4

Material loading

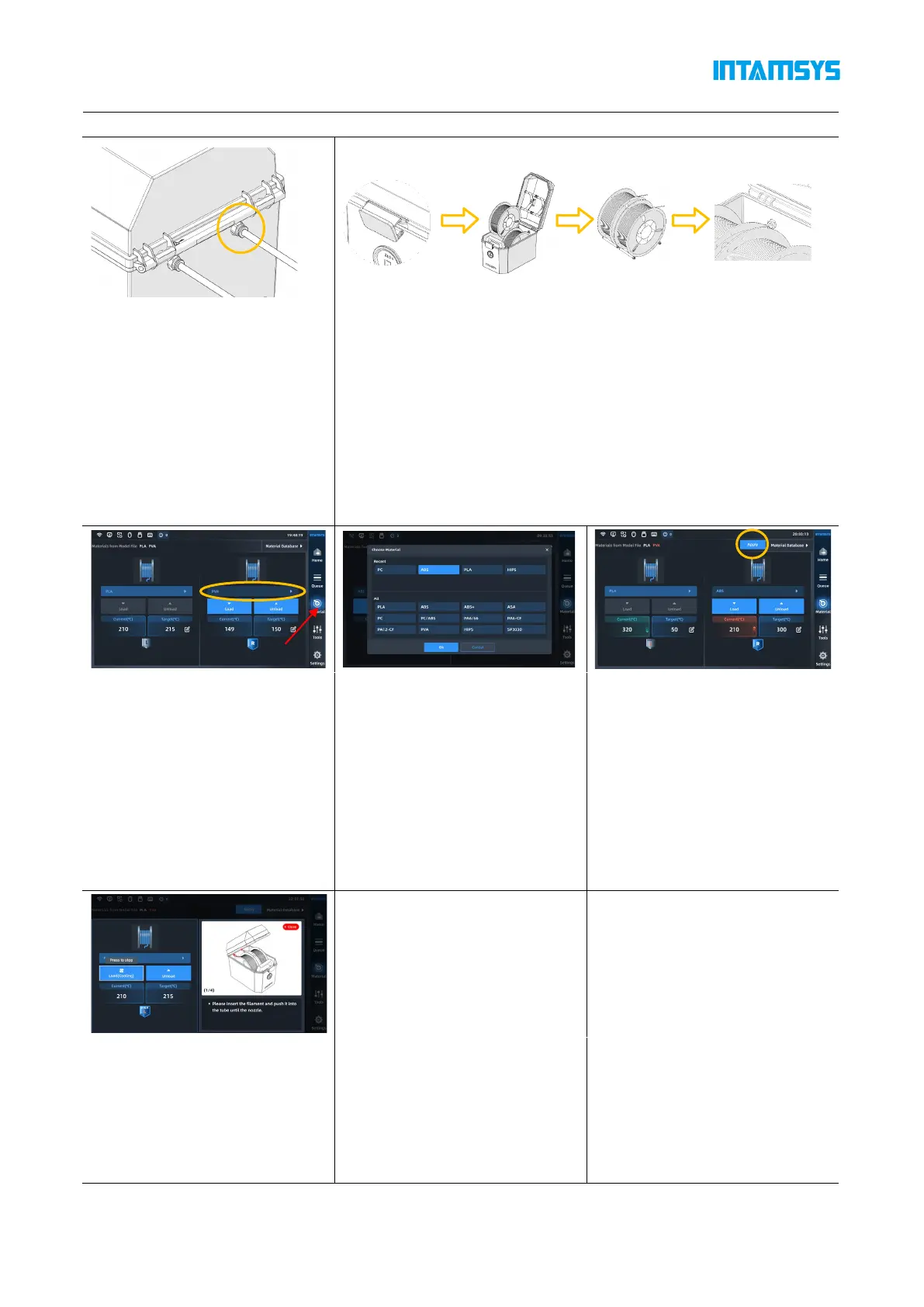

1) Insert the feeding pipe in the

accompanying accessories of the

filament box into the quick

connector and the other end into

the quick connector located on

the right side of the printer. The

feeding pipe should be inserted

to the bottom for smooth

feeding.

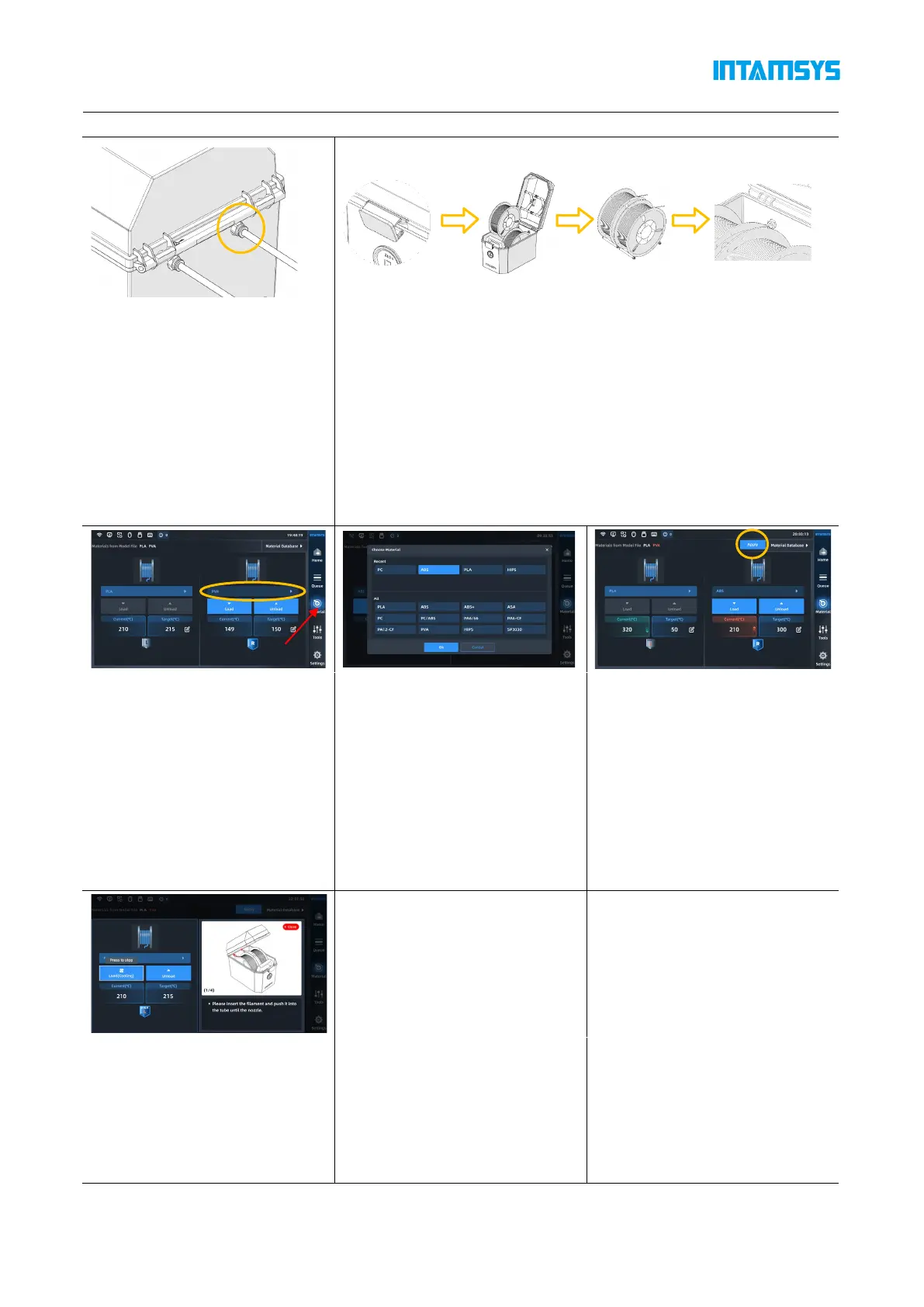

2) Unbuckle the upper cover of the filament box, place the drying box

in the front slot of the filament box, put the wire rod on the roller of

the filament box as shown in the figure, and then thread the wire rod

through the quick connector at the rear end until the material

protrudes from the feeding pipe of the printer. After manual loading

is completed, buckle the upper cover.

3) Click the "Material" button on

the screen operation interface,

click the left or right spool icon

to select the extruder to be

loaded with materials. The

highlighted icon indicates the

extruder is activated;

4) Pressing the "Material

Database" button will display

INTAMSYS materials and user-

defined materials. Materials that

we used recently and frequently

will be at the top, scroll down to

select available materials. User-

defined materials can be

configured in material database.

5) Specifically, if the material on

the printer is inconsistent with

the material settings in the G-

code print file, the system will

alert the user to check the

material. Click "Apply". Then the

material will be automatically

applied to the L&R Nozzle.

6) After selecting the material,

press the Load button to load the

material step by step according

to the pop-up wizard.

Loading...

Loading...