Machines manufactured by Hydralok, Bristol, UK

Machine enquiries, sales, after sales service :

Interpump Hydraulics (UK) Ltd t/a IMM Hydraulics (UK) : Kidderminster

Tel : (0)121 550 1115 / sales@immhydraulics.co.uk

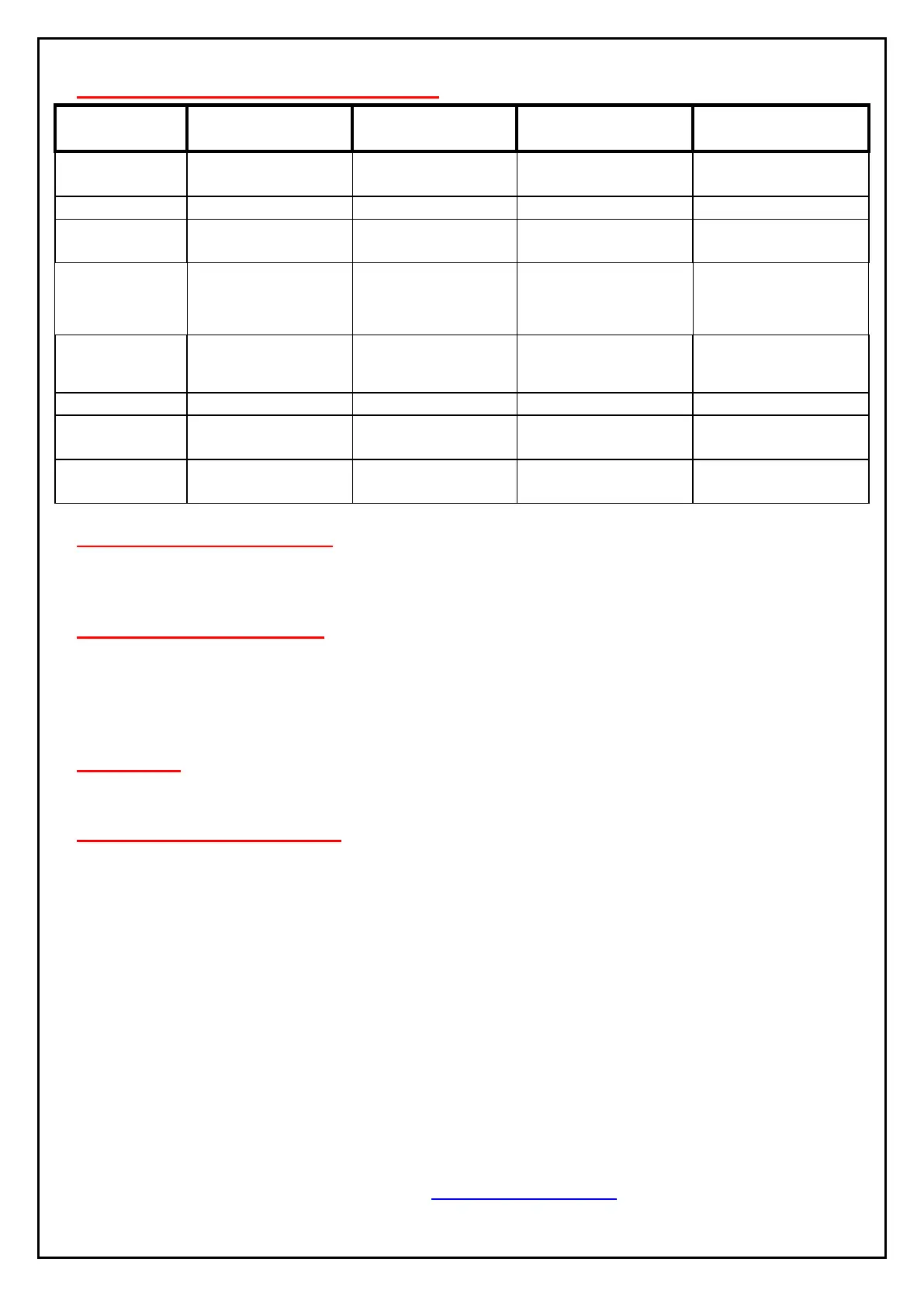

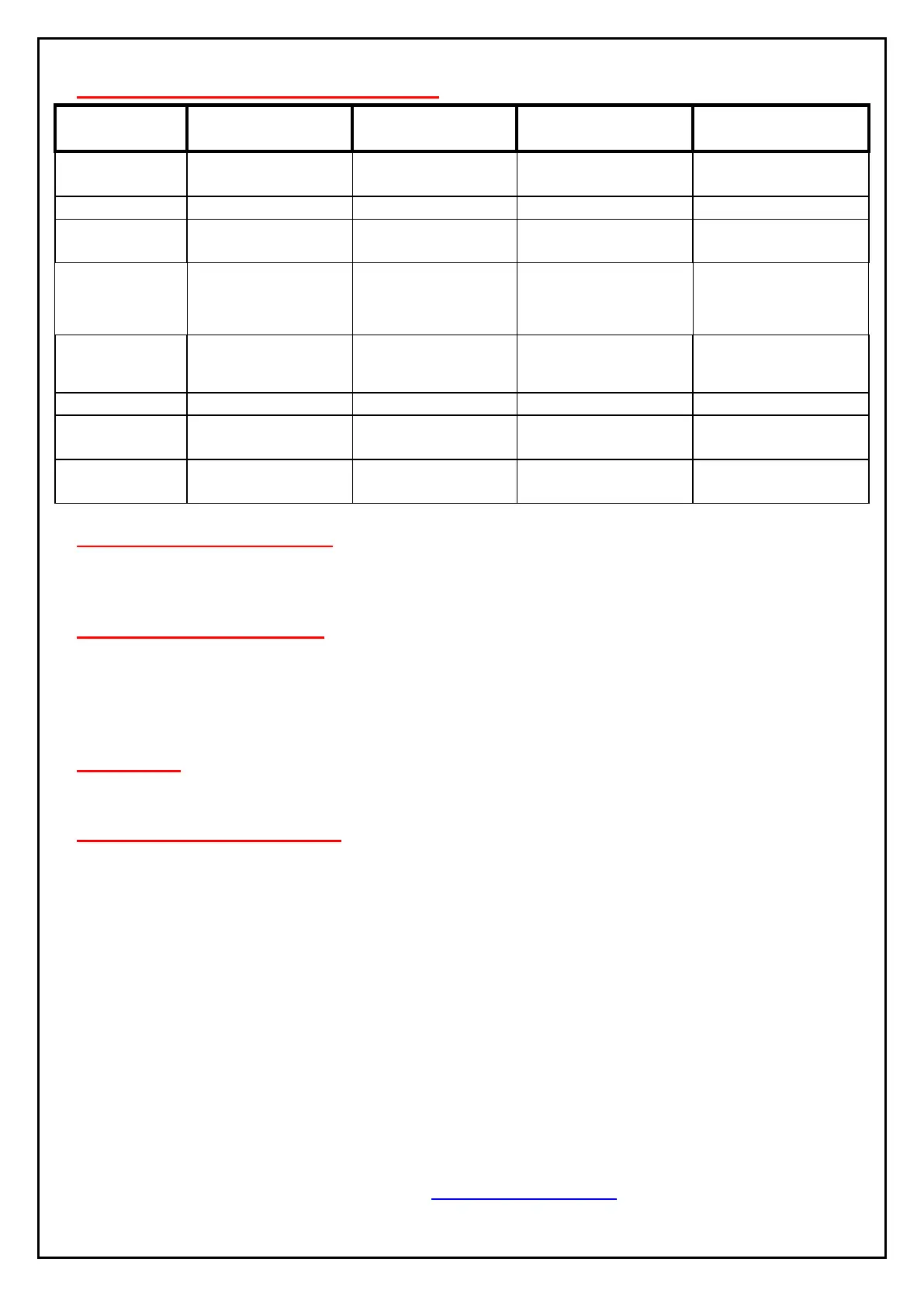

TECHNICAL / DIMENSIONAL DATA

3/16”- 2” (4 wire)

And 1½” (6 wire)

Voltage, Phase

and Frequency

Options

220/240-1- 50HZ or

220/240 - 380/440-3-50

Hz 225/280 – 440/480

60 Hz

220/240-1-50HZ or

220/240 - 380/440-3-50

Hz 225/280 – 440/480

60 Hz

220/240-1-50HZ or

220/240 - 380/440-3-50

Hz 225/280 – 440/480

60 Hz

220/240-1-50HZ or

220/240 - 380/440-3-50

Hz 225/280 – 440/480

60 Hz

16 19 22 26 30 34

40 46 52 58 64 70

16 19 22 26 30 34 40

46 52 58 64 70

16 19 22 26 30 34 40

46 52 58 64 70 76

HANDLING/TRANSPORT

The machine will normally be shipped bolted to a wooden pallet. The bolts should be removed

and the machine lifted onto the work place using suitable lifting equipment.

PRELIMINARY CHECKS

Place the machine on a flat and stable base.

Where applicable, ensure that the power supply line is fitted with a differential safety breaker and

overload cut-out.

LIGHTING

The equipment does not have its own lighting and so it must be used in a suitably illuminated area.

ROUTINE MAINTENANCE

Ensure that moving parts are always lightly greased. Where applicable, check periodically that the

limit switches and emergency controls are in good working order.

At the top of the machine base, remove the oil filler cap and check that the oil level is correct.

Where necessary add oil (ISO 32 Hydraulic oil).

Loading...

Loading...