Optidrive ODP-2 User Guide Revisions 2.10

4.8. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm

2

/ 30 – 12 AWG.

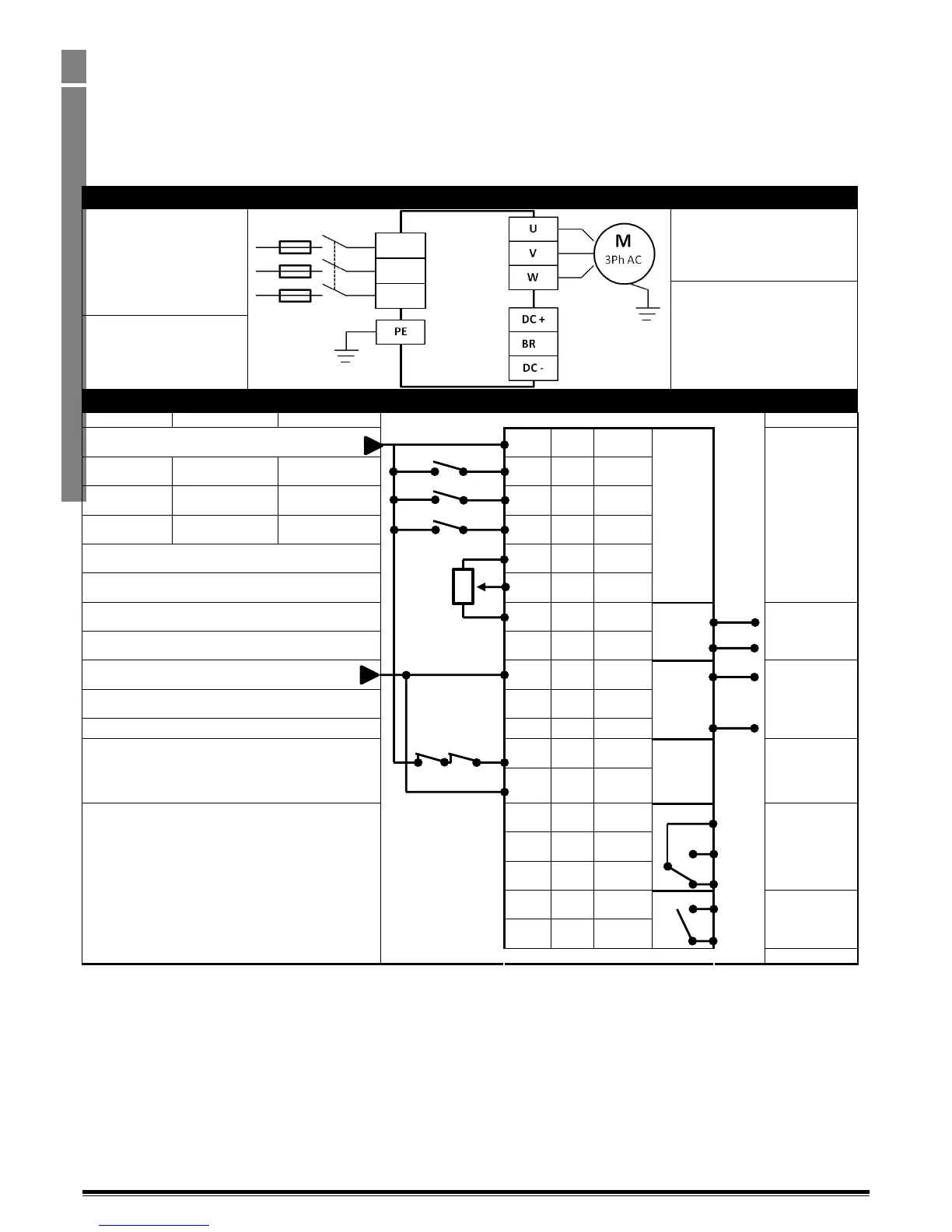

4.9. Connection Diagram

4.9.1. Power Terminal Designations

Incoming Mains Power Supply

For 1 Phase Supply, connect to

L1/L and L2/N terminals.

For 3 Phase Supply, connect to

L1, L2 & L3 terminals.

Phase sequence is not

important.

Motor Connections

Connect the motor to the U, V & W

terminals.

The motor earth must be

connected to the drive

Optional Brake Resistor & DC Bus

Connections

Where a Brake resistor is used, it

must be connected to the BR and

DC+ terminals

Protective Earth / Ground

connection.

The drive must be Earthed /

Grounded

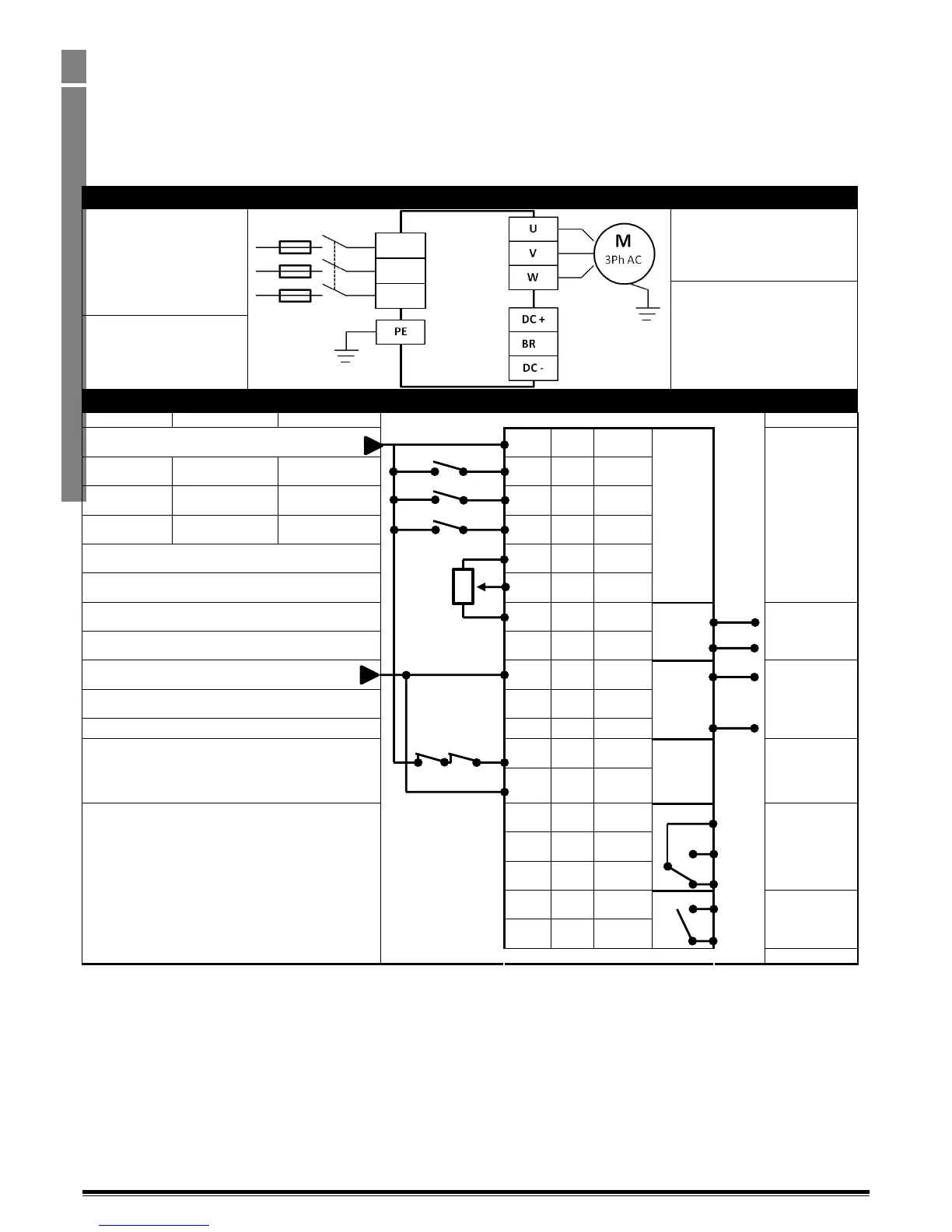

4.9.2. Control Terminal Connections & Factory Settings

+24V Supply (100mA) / External Input

Digital Inputs : 8 – 30 Volt DC

+ 10 Volt, 10mA Output

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

0 Volt Supply / External Input

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

SAFE TOQUE OFF input

Also refer to section 4.10.7 “STO“Electrical Installation

Logic High = 18-30 Vdc (“SAFE TORQUE OFF” Standby

mode)

Relay Contacts (Terminals 14-18)

250VAC / 30VDC

5A Maximum

Default

Function :

Healthy

/ Fault

Default

Function :

Running

Loading...

Loading...