Optidrive ODP-2 User Guide Revision 2.10

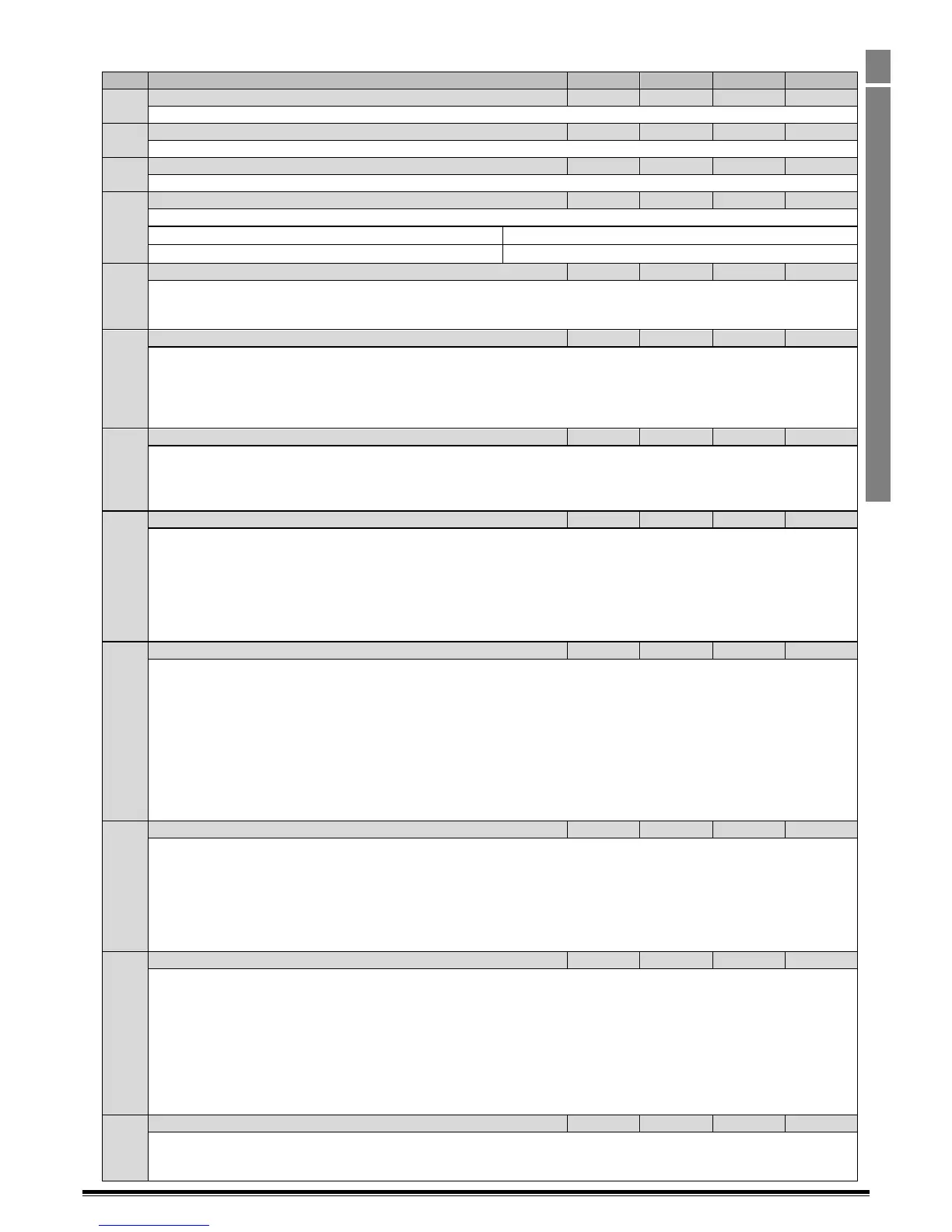

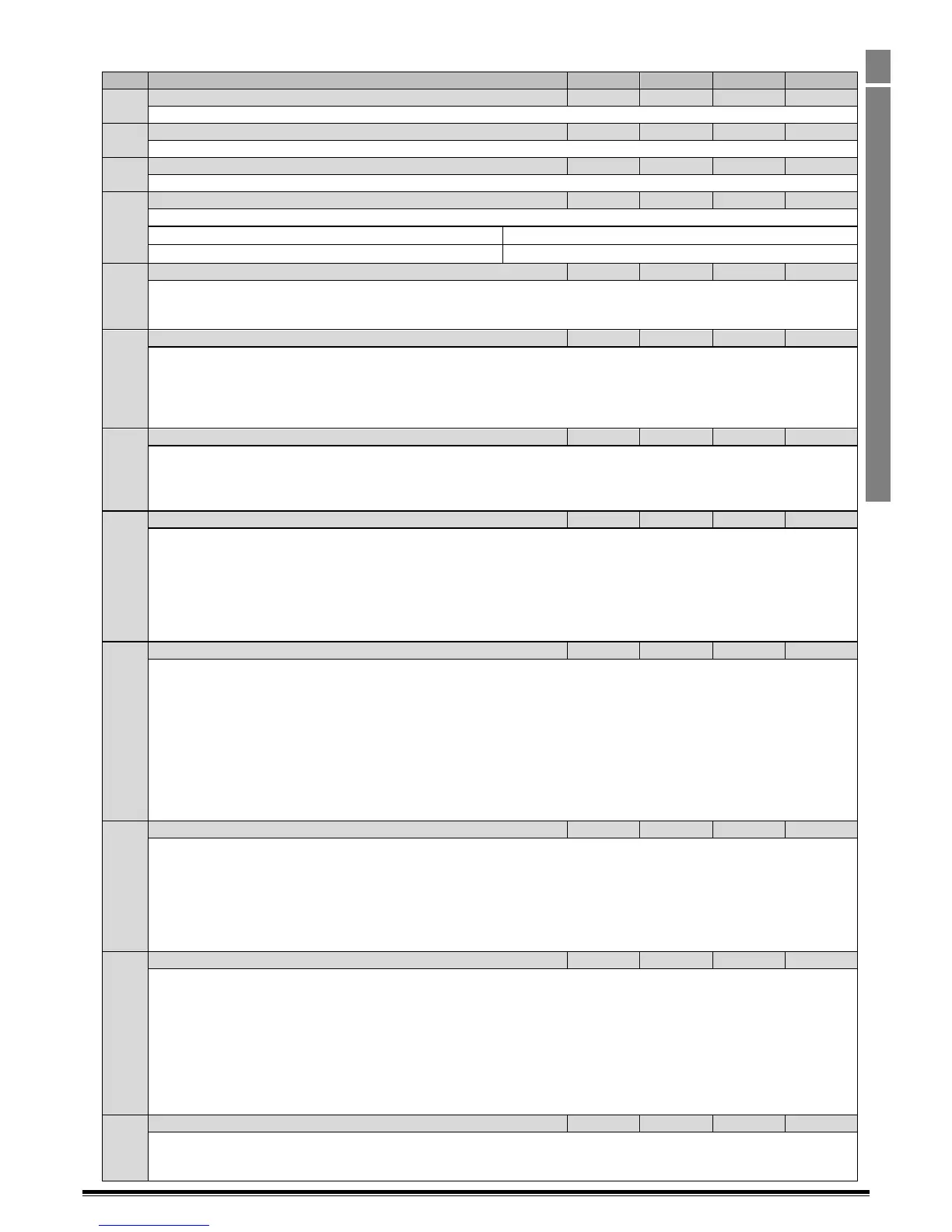

8.4. Parameter Group 5 – Communication Parameters

Sets the fieldbus address for the Optidrive

Sets the baud rate when CAN Open communications are used

Sets the baud rate when Modbus RTU communications are used

Sets the expected Modbus telegram data format as follows :-

: No Parity, 1 stop bit

: Odd parity, 1 stop bit

: No parity, 2 stop bits

: Even parity, 1 stop bit

Communications Loss Timeout

Sets the watchdog time period for the communications channel. If a valid telegram is not received by the Optidrive within this

time period, the drive will assume a loss of communications has occurred and react as selected below. Setting to zero disables

the function.

Communications Loss Action

Controls the behaviour of the drive following a loss of communications as determined by the above parameter setting.

0 : Trip & Coast To Stop

1 : Ramp to Stop Then Trip

2 : Ramp to Stop Only (No Trip)

3 : Run at Preset Speed 8

Selects whether the acceleration and deceleration ramps are control directly via the Fieldbus, or by internal drive parameters P1-

03 and P1-04.

0 : Disabled. Ramps are control from internal drive parameters

1 : Enabled. Ramps are controlled directly by the Fieldbus

Fieldbus Process Data Output Word 4 Select

When using an optional fieldbus interface, this parameter configures the parameter source for the 4

th

process data word

transferred from the drive to the network master during cyclic communications

0 : Output Torque – 0 to 2000 = 0 to 200.0%

1 : Output Power – Output power in kW to two decimal places, e.g. 400 = 4.00kW

2 : Digital Input Status – Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc.

3 : Analog Input 2 Signal Level – 0 to 1000 = 0 to 100.0%

4 : Drive Heatsink Temperature – 0 to 100 = 0 to 100°C

Fieldbus Process Data Output Word 3 Select

When using an optional fieldbus interface, this parameter configures the parameter source for the 3

rd

process data word

transferred from the drive to the network master during cyclic communications

0: Motor current – Output current to 1 decimal place, e.g. 100 = 10.0 Amps

1: Power (x.xx kW) Output power in kW to two decimal places, e.g. 400 = 4.00kW

2: Digital input status – Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc.

3: Analog Input 2 Signal Level - 0 to 1000 = 0 to 100.0%

4: Drive Heatsink Temperature – 0 to 100 = 0 to 100°C

5: User register 1 – User Defined Register 1 Value

6: User register 2– User Defined Register 1 Value

7: P0-80 value – User Selected data value.

Fieldbus Process Data Input Word 4 Select

When using an optional fieldbus interface, this parameter configures destination for the 4

th

process data word received by the

drive from the network master during cyclic communications

0: Fieldbus Ramp Control – This option must be selected if the drive acceleration and deceleration ramps are to be controlled

from the fieldbus. P5-07 must also be set to 1 to enable this function.

1: User register 4 – The value received by the drive in PDI 4 is transferred to User Register 4. This option allows the function of

the process data word to be defined in Parameter Group 9. In this case, User Register 4 should not be written to within any PLC

function code, although the value can be read.

Fieldbus Process Data Input Word 3 Select

When using an optional fieldbus interface, this parameter configures destination for the 3

rd

process data word received by the

drive from the network master during cyclic communications

0: Torque limit/reference – This option must be selected if the drive output torque limit / setpoint is to be controlled from the

fieldbus. This also requires setting P4-06 = 3.

1: User PID reference register – This option allows the setpoint to the PID controller to be received from the Fieldbus. In order

for this option to be used, P9-38 must be set to 1, and the PID User setpoint must not be utilised within the PLC function.

2: User register 3 - The value received by the drive in PDI 3 is transferred to User Register 3. This option allows the function of the

process data word to be defined in Parameter Group 9. In this case, User Register 3 should not be written to within any PLC

function code, although the value can be read.

Allows the user to configure an additional delay between the drive receiving a request via the Modbus RTU interface, and

transmitting a reply. The value entered represents the delay in addition to the minimum delay permissible according to the

Modbus RTU specification, and is expressed as the number of additional characters.

Loading...

Loading...