Page 31

Relubrication intervals are based on continuous operation in ambient temperature up to +20ºC and should be

reduced as follows for increases in ambient temperature +25ºC x 0.8, +30ºC x 0.65, +35ºC x 0.5, +40ºC x 0.4.

Above +40ºC consult our Technical Department.

Data is provided as a guide only and intervals should be shortened/lengthened based on service experience

with the particular application.

ASSEMBLY AND DISMANTLING

BLz series vibrator motors do not contain any user serviceable parts. If repairs or replacement parts are

required, the user is directed to instruction (5) under ‘operational conditions’ on page 1.

REMOVAL AND FITTING OF BEARINGS:

Bearings should only be removed when absolutely necessary. A press & / or appropriate extractor tools

should be used to remove the outer race, cage and rollers from the bearing housing and the inner race from

the shaft. If the same bearings are to be used again, wash them thoroughly in a mixture of petrol and light

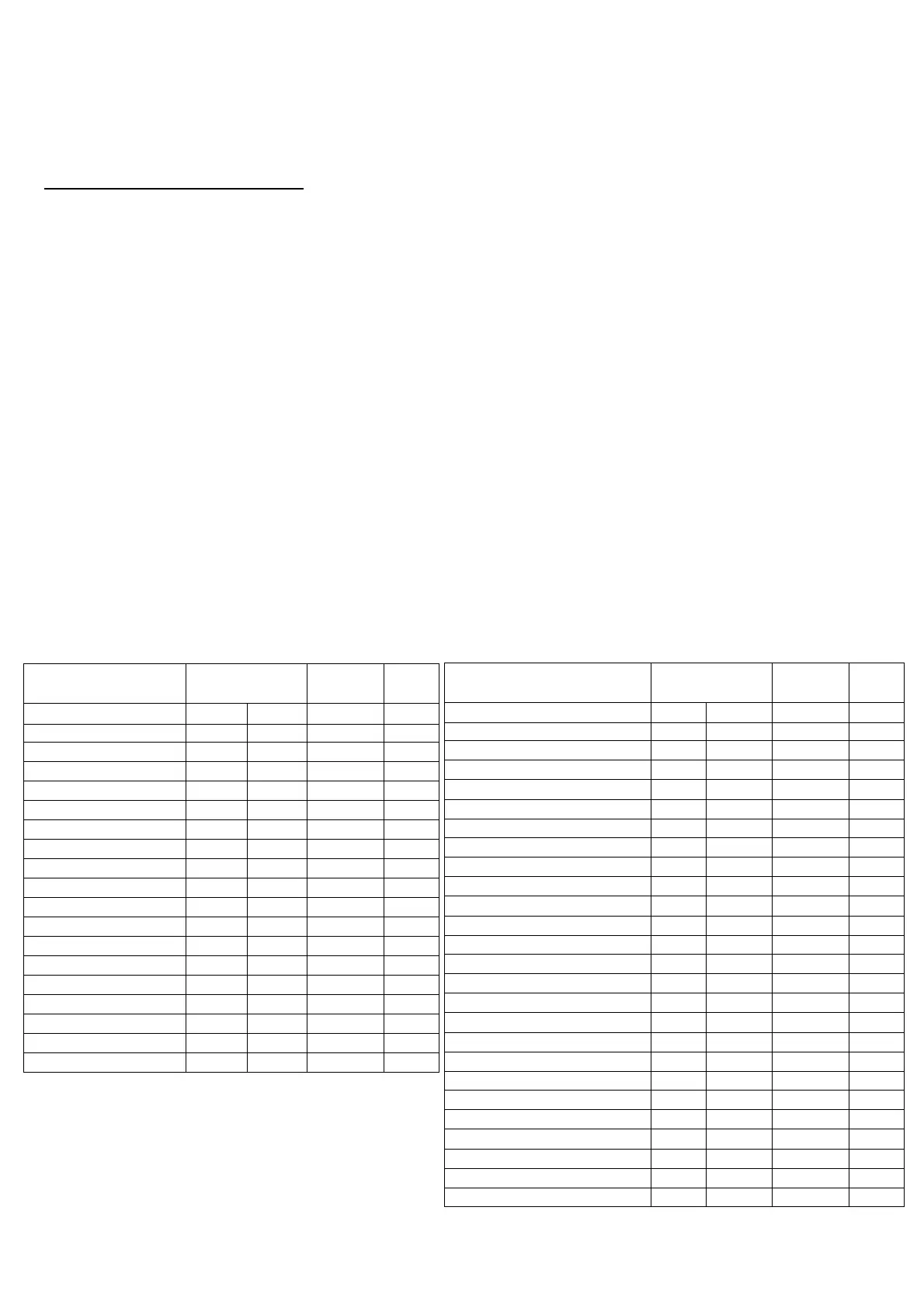

machine oil. Replacement bearings must have the special features recommended in the following table.

Since some of the interference fit can be lost by removing and fitting new bearings they should always be re-

fitted using Loctite 638 or equivalent. Refit each bearing into the bearing housing using a press. Lightly pack

the outer race and rollers with grease, forcing some well into the working parts.

The inner race of the bearing should be placed in a bath of clean mineral oil and heated to a temperature of

+80

o

C (180

o

)F. The inner race should be pushed into place in the correct orientation, then held against the

shaft shoulder until it contracts sufficiently to grip the shaft. Smear the inner race with grease & place the

shaft/rotor assembly carefully inside the stator bore within the main housing and fit the bearing housings, outer

grease retainers, weights & end covers. Use Loctite 242 (or equivalent) on screws when refitting bearing

housing. Check that the shaft has the correct end float.

BLz 03, 05, 15, 20, 22, 24/25-8/2, -7.5/4 and 4/6 have shielded ball bearings and should be replaced if

damaged.

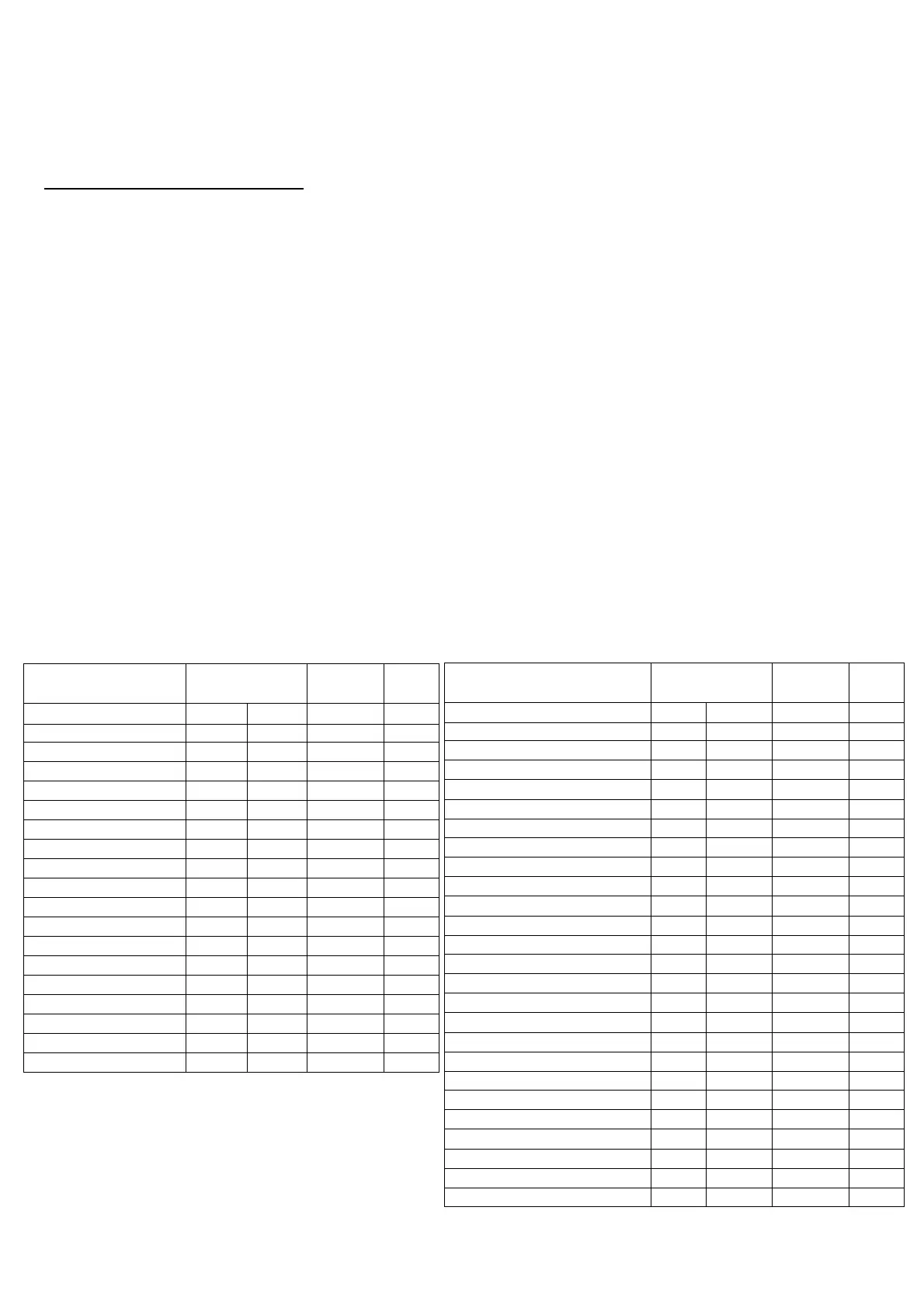

GREASING INSTRUCTIONS – RELUBRICATION CHART – PER BEARING

Loading...

Loading...