Page 8

‘L’ SERIES VIBRATOR INSTALLATION AND MAINTENANCE

RECEIPT AND STORAGE

Each vibrator is tested and inspected on completion. Whilst every care is taken during transit they should be

inspected on receipt and any defects immediately reported to the carrier and supplier. When not for immediate

use, they can be stored for up to two years if kept in a clean, dry and temperate atmosphere, free from

vibration. After more than 2 years of storage the bearing grease should be replaced before the motor is used.

INSTALLATION GUIDANCE NOTES:

Mechanical: Inspect vibrator for any physical damage and check that rotor shaft rotates freely. Remove paint

masking stickers from motor mounting holes. ALL mounting surfaces MUST be flat and free of paint, dirt and

scale. Fixing bolts should be tightened as recommended below and tightness checked after initially running

the vibrator. Bolts and nuts should not be reused. Please ensure there is at least 50mm of clearance between

the vibrator and any surrounding static structure.

IMPORTANT - GAPS BETWEEN THE VIBRATOR FOOT AND MATING SURFACES AND INCORRECT

BOLT TIGHTNESS WILL CAUSE BOLT BREAKAGE AND DAMAGE TO THE VIBRATOR.

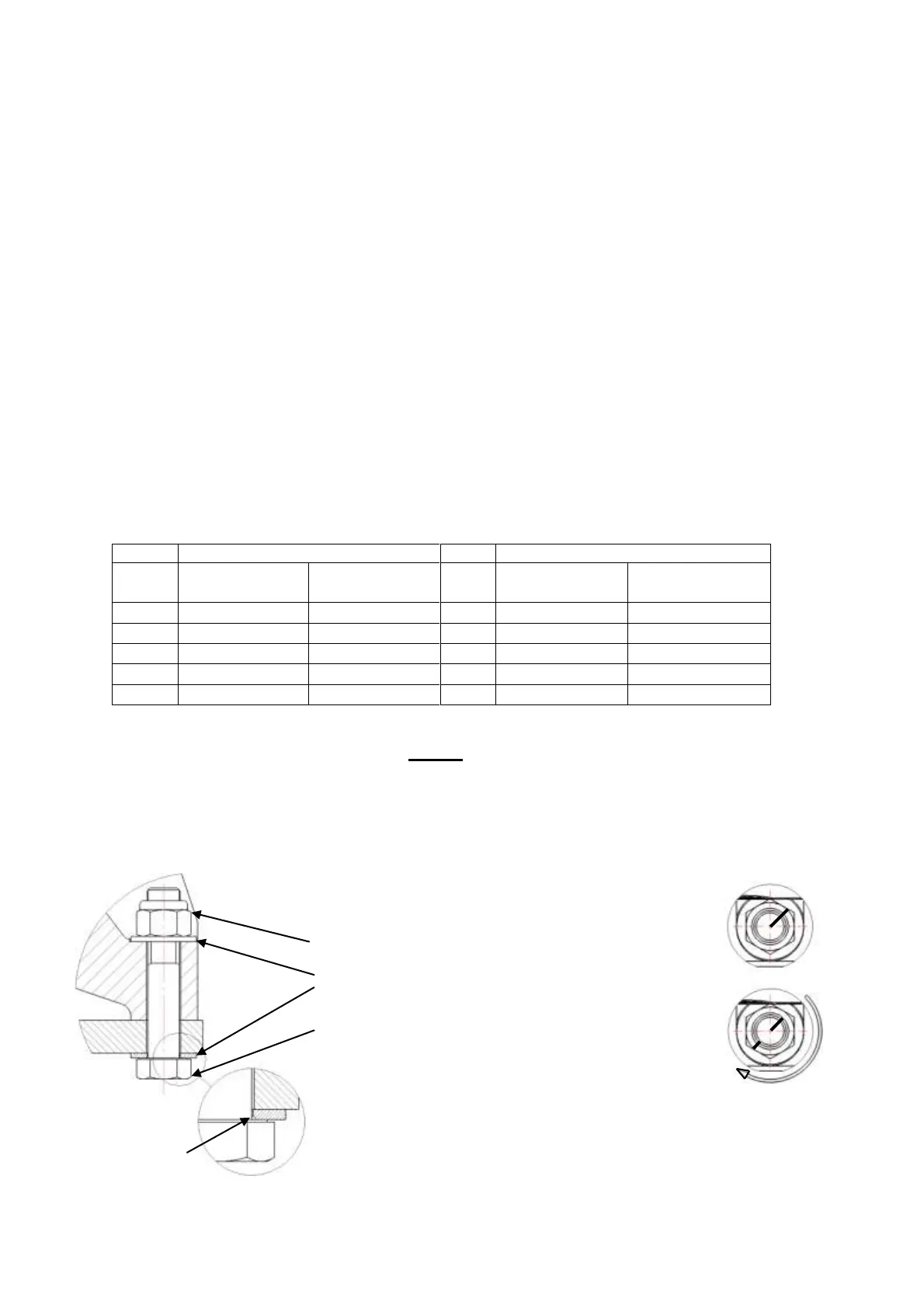

Fixing bolt tightening: Use Grade 8.8 bolts with Grade 8 self locking nuts, torqued to values below. Figures

below apply to un-plated dry threads.

Where capscrews are used with locking nuts, Grade 10 nuts must be fitted.

Use plain washers for BLz 03 - BLz 24 (aluminium frames) Not BLz22. If washers are used for BLz22 - BLz80

(cast iron frames) Not BLz24, hardened washers (PSN 612 to DIN 6916 or BS EN 14399-6) must be fitted.

Setscrews/Bolts

Grade 8.8

Setscrews/Bolts

Grade 8.8

With figures marked * a torque multiplier will be required.

Use the above figures for all screws except out of balance weights. (see page 29)

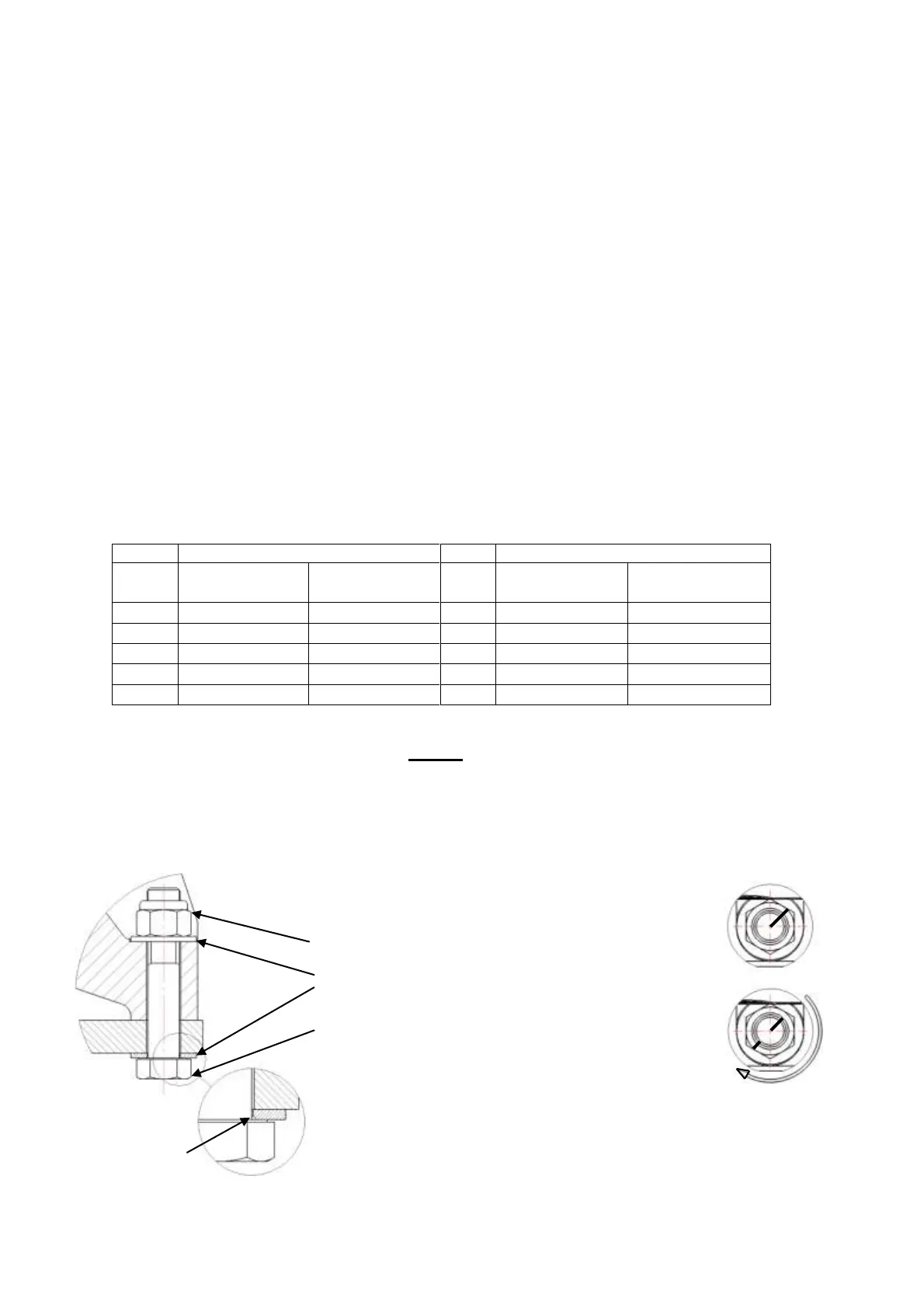

BLz 75 - 80: Half turn method.

In exceptional circumstances where tooling is not available, the half turn method may be used.

PSN 661 – High Strength nut

PSN 612 – Hardened washer under

bolt head and nut

PSN 780 - High strength bolt

Remove any paint, dirt or scale from all mating surfaces.

Fit hardened washer (PSN 612) under bolt head and nut. Pre-tighten until all mating surfaces are in contact.

Mark nuts and bolts as shown in fig. 2 and slog nut one half turn until marks are as shown in fig. 3.

Washer Chamfer

this side.

Loading...

Loading...