Model

-RL1

-RL1

-RL1

-RL1

-RL1

-RL1

Voltage

Nominal voltage of DC breaker should be

larger than maximum voltage of

battery.

Current[A]

160A

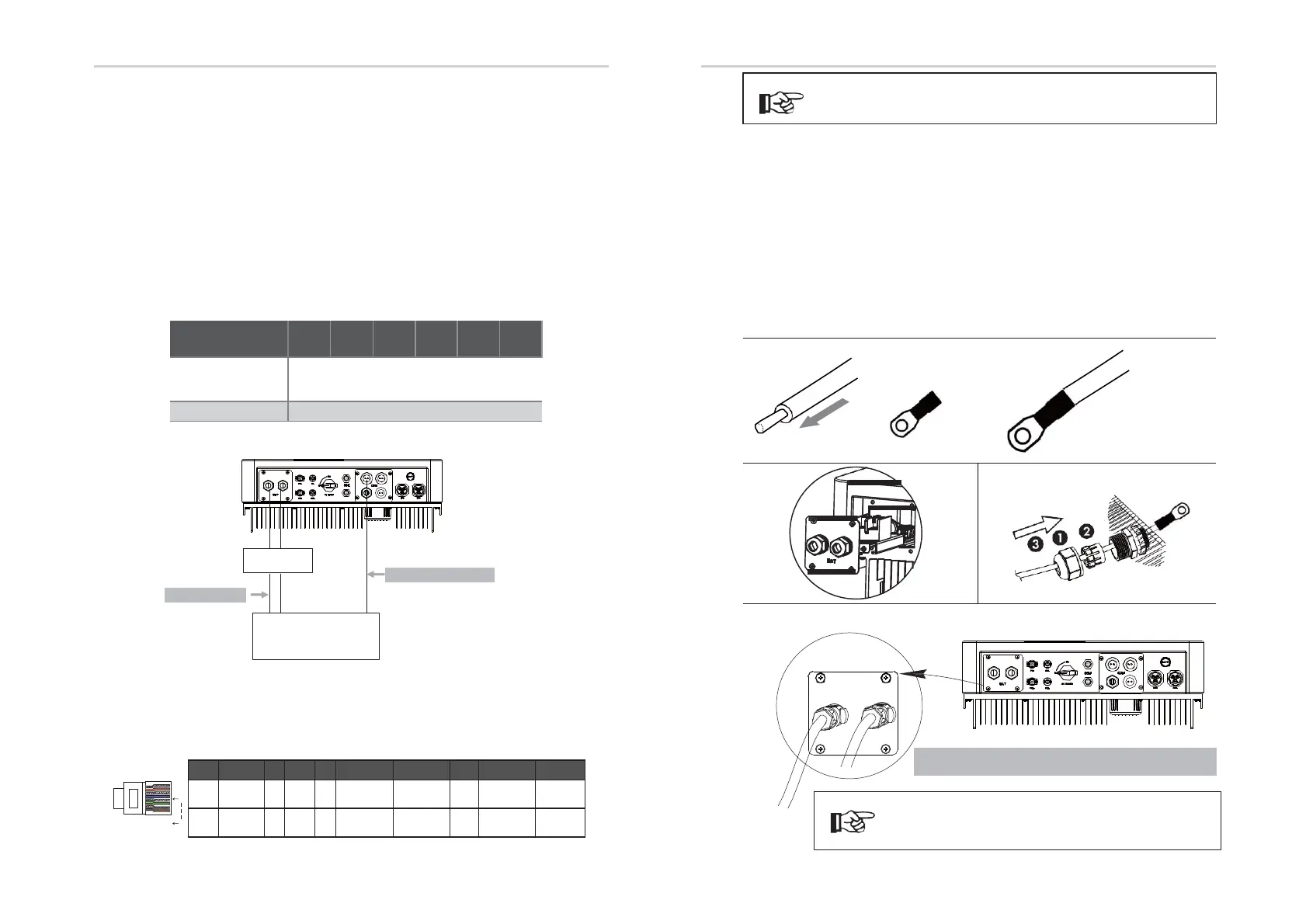

6.4 Battery

Connection

Charging & discharging system of BD series inverter is designed for

high-voltage lithium battery.

Before choosing battery, please note the maximum voltage of battery

can not

exceed 59V and the rated voltage of battery can not exceed 48V,

and the battery communication should be compatible with BD Hybrid

inverter.

Battery breaker

Before connecting to battery, please install a nonpolarized DC breaker to

make sure inverter can be securely disconnected during maintanance.

Battery connection

diagram

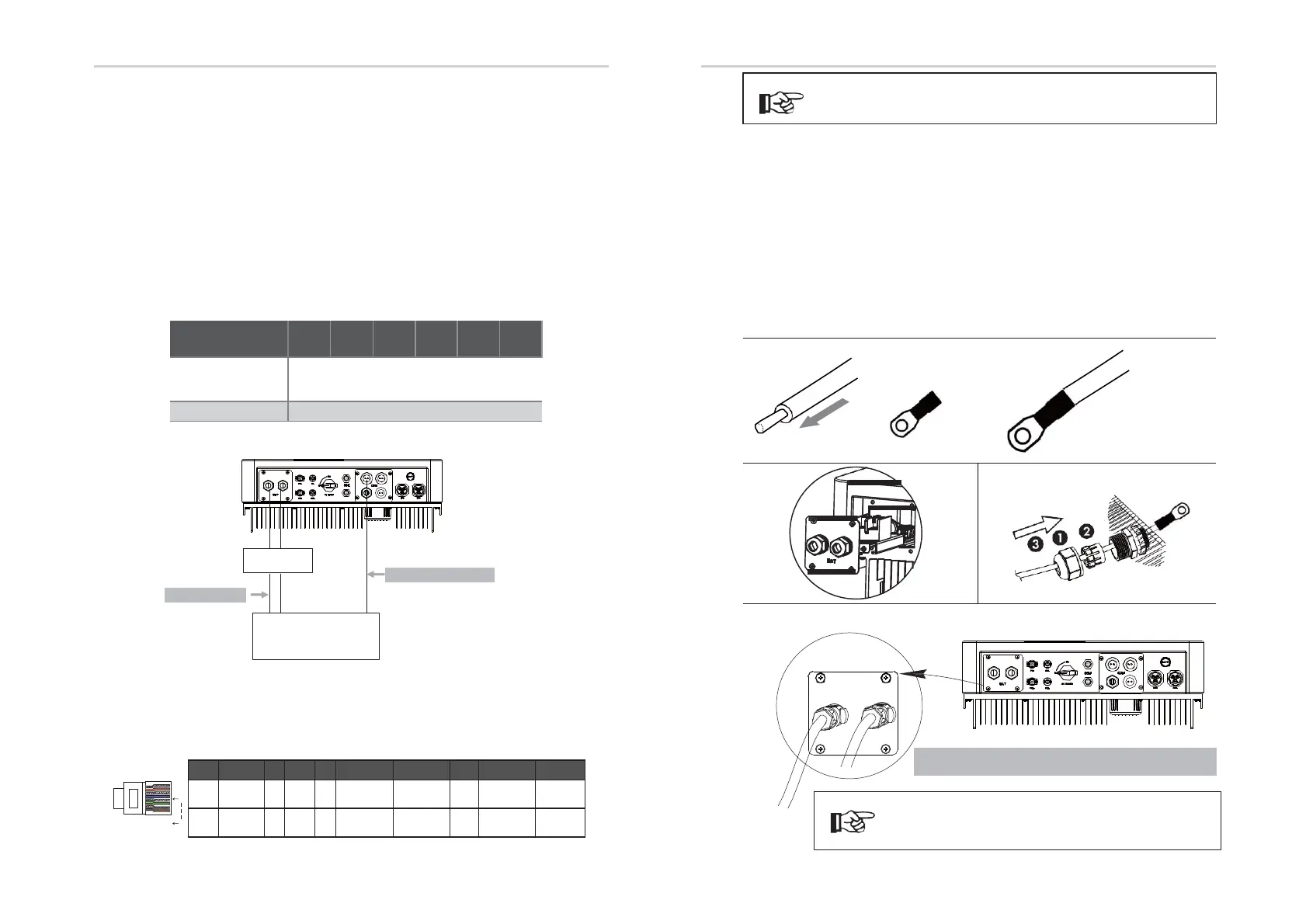

Power Connection Steps:

Step1. Choose the 2 AWG wire and strip the cable to 15mm.

Step2. Select two O-terminals with an aperture of M6.

Step3. Insert the stripping line into the O-terminal and clamp it with a crimping

clamp. Step4. Remove waterproof cover plate.

Step5. Disassemble the waterproof connector and pass the cable through

the waterproof connector.

S. tep6. Connect the cable to the terminal of the inverter .

.Step7. Assemble waterproof connectors and waterproof covers plate.

+

CAN/ RS485

Nonpolarized

DC breaker

Power connection

48V lithium battery

Note: When working with Pylontech batteries, It is recommended the number of battery

module (H48050-15S) is 2-7 and the number of battery manager system (SC0500A-100S) is 1.

Communication connection

BMS PIN Definition

Communication interface bewteen inverter and battery is RS485 or CAN

with a RJ45 connector.

Note!

The battery communication can only work when the battery

BMS is compatible with the inverter.

1

8

Electrical Connection Electrical Connection

Step1,2,

3.

Step4

.

Step5

.

Step6,7.

PIN

2

3

4

5

6 7 8

fi

on

X

X

BMS_CANH

BMS_CANL

X

X X

fi

on

X X

X X GND

BMS_485A

When using RS485 protocol, please note that PIN2 must be disconnected.

BAT

Note: BAT port, not PV port!The positive pole on the left and

the negative pole on the right.

Note!

Positive and negative lines are not allowed to

reverse.

30

31

Loading...

Loading...