2: INSTALLATION

Iridium Pilot™ Installation Guide 17

2. Provide a water barrier to prevent the seawater (electrolyte) from reaching the area between the dissimilar

metals. Again 3-M brand 5200 adhesive, or equivalent, can be used for this purpose to cover all the fasteners

and areas between the anges.

These two steps should signicantly reduce the possibility galvanic corrosion and structural failure of the

adaptor mounting bracket.

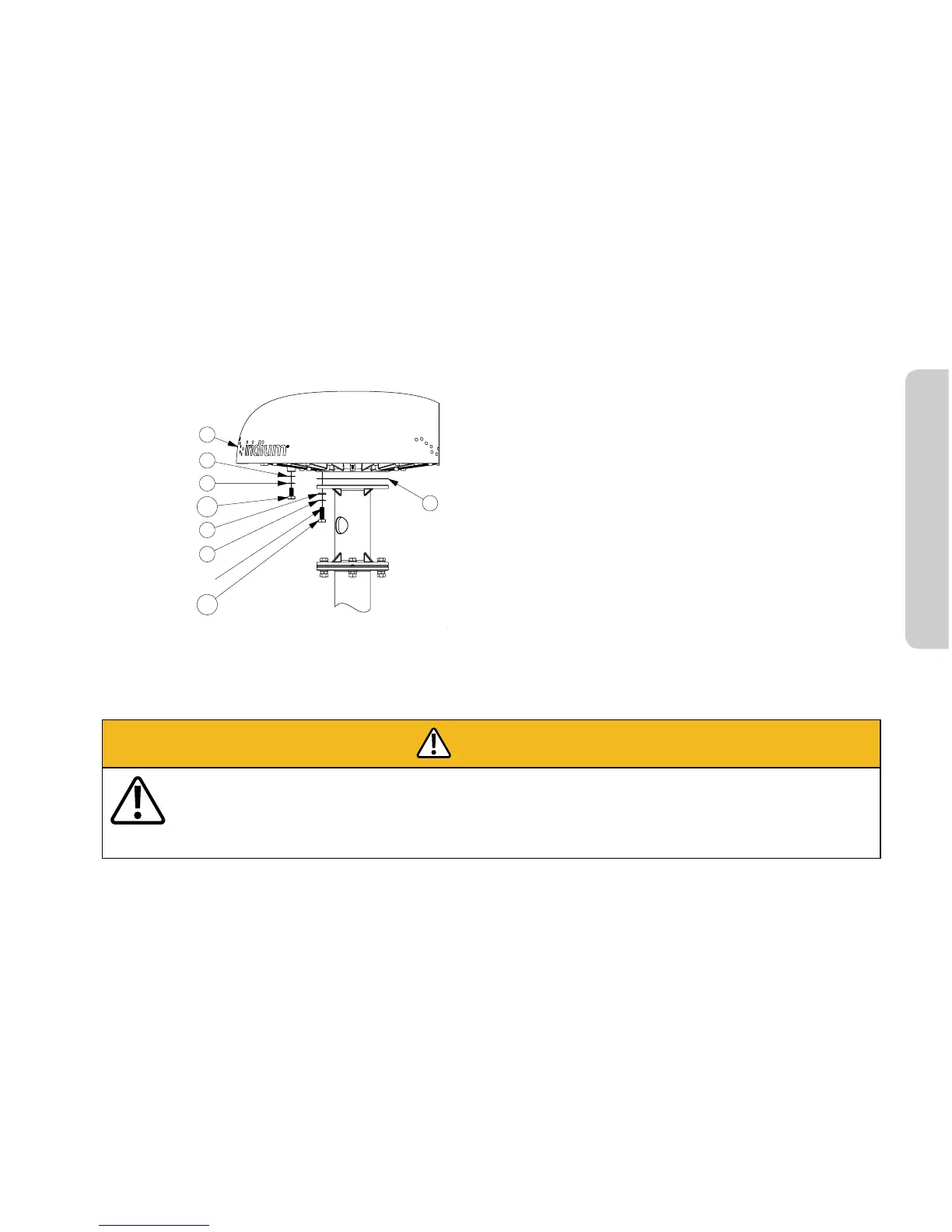

ADE Mounting

There is more than one approach that can be taken to install the ADE. The installation of the ADE is dependent

on the vessel structure. Follow these generic steps to install the ADE:

1. Fasten mounting bracket to mounting pole per “Recommended Stand Mounting” instructions below and in

Appendix D.

Figure 9.

STEPS 12-19

3

5

1

9

APPLY ANTI-SEIZE

COMPOUND HERE

11

10

9

9

INSTALLATION INSTRUCTIONS:

RECOMMENDED STAND MOUNTING

•

NOTE: SHIP-SIDE MOUNT MAY DIFFER FROM THE EXAMPLE SHOWN. NEOPRENE BONDED STAINLESS

STEEL WASHERS ARE INCLUDED TO PROTECT THE ANTI-CORROSION COATING ON THE STAND AND TO

PREVEND GALVANIC CORROSION OF THE ASSEMBLY. 316 STAINLESS STEEL HARDWARE IS

RECOMMENDED FOR INSTALLATION.

TAKE CARE WHEN TRANSPORTING THE RADOME (1) AND STAND (2) SO AS NOT TO DAMAGE THE

1.

CORROSION RESISTANT COATINGS

PLACE AN ISOLATION GASKET (3) ONTO THE SHIP'S MOUNTING POST (8)

2.

PLACE THE STAND (2) ONTO THE ISOLATION GASKET, WITH THE SLOTTED SIDE FACING DOWN

3.

SLIDE A NEOPRENE BONDED ISOLATION WASHER (5) ONTO AN M10 HEX HEAD BOLT (4), WITH ITS

4.

METAL SIDE CONTACTING THE BOLT

SLIDE THIS BOLT ASSEMBLY THROUGH THE SLOT IN THE STAND THEN THROUGH THE HOLE IN THE SHIP'S

5.

MOUNTING POST

SLIDE ON ANOTHER ISOLATION WASHER WITH THE RUBBER SIDE FACING THE MOUNTING POST

6.

THREAD ON A JAM NUT (6) FINGER TIGHT

7.

THREAD ON A HEX NUT (7)

8.

REPEAT STEPS 4-8 FOR THE REMAINING THREE BOLTS

9.

TIGHTEN THE JAM NUTS UNTIL COMPRESSION IS EVIDENT IN THE ISOLATION WASHERS

10.

FOR ALL FOUR BOLTS: PREVENTING THE JAM NUT AND BOLT FROM TURNING, TIGHTEN THE HEX NUT

11.

AGAINST THE JAM NUT UNTIL THEY LOCK, TAKING CARE NOT TO OVERTIGHTEN

RADOME MOUNTING•

NOTE: GROUNDING LUG ON RADOME BASE MUST BE FACING STERN. ALIGN SHIP-SIDE MOUNT

ACCORDING TO THE DIAGRAM BELOW THESE INSTRUCTIONS

PLACE AN ISOLATION GASKET (3) ON TOP OF THE STAND

12.

ROUTE THE POWER/DATA CABLE (NOT PICTURED) THROUGH EITHER THE BOTTOM OF THE STAND OR

13.

THROUGH ITS SIDE HOLE, UP THROUGH THE TOP HOLE IN THE STAND. PLUG THE CABLE INTO THE

CONNECTOR ON THE BOTTOM OF THE RADOME

PLACE THE RADOME ONTO THE STAND, WITH THE ARROW ON THE BASE POINTING TOWARD THE BOW

14.

SLIDE A LOCK WASHER (9) THEN AN ISOLATION WASHER (5) ONTO AN M10x30mm HEX HEAD BOLT

15.

(10). THE METAL SIDE OF THE ISOLATION WASHER SHOULD FACE THE LOCK WASHER. APPLY ANTI-SEIZE

COMPOUND (12, NOT PICTURED) TO THE BOLT THREADS

SLIDE THE PREPARED BOLT UP THROUGH THE STAND, AND FINGER TIGHTEN INTO THE DOME ARRAY

16.

REPEAT STEPS 12 AND 14 FOR THE REMAINING THREE BOLTS

17.

TORQUE THE FOUR BOLTS UNTIL COMPRESSION IS EVIDENT IN THE ISOLATION WASHER

18.

ATTACH GROUND CABLE BETWEEN TWO LOCK WASHERS (9) ON THE 20mm M10 BOLT (11) AND

19.

TIGHTEN INTO GROUND POST

STARBOARD

PORT

STERN

BOWBOW

STERN

PORT

STARBOARD

CORRECT SHIP-SIDE MOUNT ORIENTATION:

INCORRECT SHIP-SIDE MOUNT ORIENTATION

DO NOT USE

REVISIONS

REV.

DESCRIPTION

DATE

PA1

INITIAL CONTROLLED DRAWING

4/27/2011

PA2

DIFFERENT HARDWARE CHOICE, NEW INSTALLATIOIN

INSTRUCTIONS

5/9/2011

PA3

HARDWARE CHANGE, ANTI-SEIZE COMPOUND

ADDED, INSTALLATION INSTRUCTIONS UPDATED

5/19/2011

PA4

ADDED GROUND BOLT, REPLACED BUTTON HEAD

SCREW WITH LONGER HEX HEAD, CHANGED PART

DESCRIPTIONS, ADDED SHIP-SIIDE MOUNT

ORIENATATION

5/20/2011

PA5

LOCK WASHERS ADDED TO GROUND BOLT, ASSEMBLY

INSTRUCTIONS UPDATES

5/23/2011

PA6

ISOLATION GASKET ADDED BETWEEN HST100 AND ODU

STAND, INSTRUCTION SUPDATED

10/28/2011

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

HST100

RADOME ASSEMBLY

1

2

ODU-STAND

ODU STAND

1

3

GSK113

RUBBER ISOLATION GASKET

2

4

INSTALLER PROVIDED

M10 316 S/S HEX BOLT

4

5

94709A418

MCMASTER RUBBER+ STEEL WASHER 3/8

12

6

INSTALLER PROVIDED

M10 JAM NUT 316 S/S

4

7

INSTALLER PROVIDED

M10 HEX NUM 316 S/S

4

8

SHIP-SIDE MOUNT

TYPICAL SHIP-SIDE MOUNT

0

9

93925A290

MCMASTER LOCK WASHER M10

6

10

93635A424

MCMASTER M10-1.5X30 MACHINE SCREW

4

11

93635A416

MCMASTER M10X20MM HEX BOLT 316 SS

1

12

ANTI-SEIZE COMPOUND

LOCTITE 2.25 OZ STICK

1

6

D

C

B

A

E

F

G

H

E

A

B

C

D

F

5

4

3

2

1

7

8

9

10

11

12

1

2

3

4

5

6

7

8

G

9

10

11

H

PA6

1:2

UNITS

mm

MATERIAL

GEOMETRIC

TOLERANCING PER

ASME Y14.5m-1994

3D REFERENCE

A-ADA101_PA5

DOCUMENT NUMBER

D-ADA101_PA6

DESCRIPTION

ISSUE DATE

SIZE

A2

REVISION

SCALE

DRAWN BY

N.MAHER

0.10

2

0.15

HOLE TO HOLE

ANGULAR DIMENSIONS

LINEAR DIMENSIONS

TOLERANCES: UNLESS

OTHERWISE SPECIFIED

THIRD ANGLE

PROJECTION

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF IRIDIUM SATELLITE

LLC AND/OR ITS AFFILIATES AND LICENSORS, UNLESS OTHERWISE STATED. NEITHER THIS DRAWING

NOR ANY SUCH INFORMATION MAY BE COPIED, REPRODUCED, TRANSMITTED, DISTRIBUTED OR

OTHERWISE USED EXCEPT AS EXPRESSLY APPROVED IN WRITING BY IRIDIUM SATELLITE LLC AND/OR

ITS AFFILIATES. NO RIGHTS OR LICENSES OF ANY KIND TO SUCH DRAWING OR INFORMATION

(INCLUDING ANY INTELLECTUAL PROPERTY RIGHTS THEREIN) ARE TRANSFERRED TO, GRANTED TO,

PROVIDED TO OR RECEIVED BY THE RECIPIENT HEREOF AS A RESULT OF THE DELIVERY HEREOF. THIS

MATERIAL MAY NOT IN WHOLE OR IN PART BE COPIED, STORED ELECTRONICALLY OR

COMMUNICATED TO THIRD PARTIES WITHOUT THE PRIOR WRITTEN AGREEMENT OF IRIDIUM.

SHEET

1 of 1

PROPRIETARY AND CONFIDENTIAL

IRIDIUM PILOT SHIP MOUNT INSTRUCTIONS

10/31/2011

STEPS 12-19

3

5

1

9

APPLY ANTI-SEIZE

COMPOUND HERE

11

10

9

9

INSTALLATION INSTRUCTIONS:

RECOMMENDED STAND MOUNTING

•

NOTE: SHIP-SIDE MOUNT MAY DIFFER FROM THE EXAMPLE SHOWN. NEOPRENE BONDED STAINLESS

STEEL WASHERS ARE INCLUDED TO PROTECT THE ANTI-CORROSION COATING ON THE STAND AND TO

PREVEND GALVANIC CORROSION OF THE ASSEMBLY. 316 STAINLESS STEEL HARDWARE IS

RECOMMENDED FOR INSTALLATION.

TAKE CARE WHEN TRANSPORTING THE RADOME (1) AND STAND (2) SO AS NOT TO DAMAGE THE

1.

CORROSION RESISTANT COATINGS

PLACE AN ISOLATION GASKET (3) ONTO THE SHIP'S MOUNTING POST (8)

2.

PLACE THE STAND (2) ONTO THE ISOLATION GASKET, WITH THE SLOTTED SIDE FACING DOWN

3.

SLIDE A NEOPRENE BONDED ISOLATION WASHER (5) ONTO AN M10 HEX HEAD BOLT (4), WITH ITS

4.

METAL SIDE CONTACTING THE BOLT

SLIDE THIS BOLT ASSEMBLY THROUGH THE SLOT IN THE STAND THEN THROUGH THE HOLE IN THE SHIP'S

5.

MOUNTING POST

SLIDE ON ANOTHER ISOLATION WASHER WITH THE RUBBER SIDE FACING THE MOUNTING POST

6.

THREAD ON A JAM NUT (6) FINGER TIGHT

7.

THREAD ON A HEX NUT (7)

8.

REPEAT STEPS 4-8 FOR THE REMAINING THREE BOLTS

9.

TIGHTEN THE JAM NUTS UNTIL COMPRESSION IS EVIDENT IN THE ISOLATION WASHERS

10.

FOR ALL FOUR BOLTS: PREVENTING THE JAM NUT AND BOLT FROM TURNING, TIGHTEN THE HEX NUT

11.

AGAINST THE JAM NUT UNTIL THEY LOCK, TAKING CARE NOT TO OVERTIGHTEN

RADOME MOUNTING•

NOTE: GROUNDING LUG ON RADOME BASE MUST BE FACING STERN. ALIGN SHIP-SIDE MOUNT

ACCORDING TO THE DIAGRAM BELOW THESE INSTRUCTIONS

PLACE AN ISOLATION GASKET (3) ON TOP OF THE STAND

12.

ROUTE THE POWER/DATA CABLE (NOT PICTURED) THROUGH EITHER THE BOTTOM OF THE STAND OR

13.

THROUGH ITS SIDE HOLE, UP THROUGH THE TOP HOLE IN THE STAND. PLUG THE CABLE INTO THE

CONNECTOR ON THE BOTTOM OF THE RADOME

PLACE THE RADOME ONTO THE STAND, WITH THE ARROW ON THE BASE POINTING TOWARD THE BOW

14.

SLIDE A LOCK WASHER (9) THEN AN ISOLATION WASHER (5) ONTO AN M10x30mm HEX HEAD BOLT

15.

(10). THE METAL SIDE OF THE ISOLATION WASHER SHOULD FACE THE LOCK WASHER. APPLY ANTI-SEIZE

COMPOUND (12, NOT PICTURED) TO THE BOLT THREADS

SLIDE THE PREPARED BOLT UP THROUGH THE STAND, AND FINGER TIGHTEN INTO THE DOME ARRAY

16.

REPEAT STEPS 12 AND 14 FOR THE REMAINING THREE BOLTS

17.

TORQUE THE FOUR BOLTS UNTIL COMPRESSION IS EVIDENT IN THE ISOLATION WASHER

18.

ATTACH GROUND CABLE BETWEEN TWO LOCK WASHERS (9) ON THE 20mm M10 BOLT (11) AND

19.

TIGHTEN INTO GROUND POST

STARBOARD

PORT

STERN

BOWBOW

STERN

PORT

STARBOARD

CORRECT SHIP-SIDE MOUNT ORIENTATION:

INCORRECT SHIP-SIDE MOUNT ORIENTATION

DO NOT USE

REVISIONS

REV.

DESCRIPTION

DATE

PA1

INITIAL CONTROLLED DRAWING

4/27/2011

PA2

DIFFERENT HARDWARE CHOICE, NEW INSTALLATIOIN

INSTRUCTIONS

5/9/2011

PA3

HARDWARE CHANGE, ANTI-SEIZE COMPOUND

ADDED, INSTALLATION INSTRUCTIONS UPDATED

5/19/2011

PA4

ADDED GROUND BOLT, REPLACED BUTTON HEAD

SCREW WITH LONGER HEX HEAD, CHANGED PART

DESCRIPTIONS, ADDED SHIP-SIIDE MOUNT

ORIENATATION

5/20/2011

PA5

LOCK WASHERS ADDED TO GROUND BOLT, ASSEMBLY

INSTRUCTIONS UPDATES

5/23/2011

PA6

ISOLATION GASKET ADDED BETWEEN HST100 AND ODU

STAND, INSTRUCTION SUPDATED

10/28/2011

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

HST100

RADOME ASSEMBLY

1

2

ODU-STAND

ODU STAND

1

3

GSK113

RUBBER ISOLATION GASKET

2

4

INSTALLER PROVIDED

M10 316 S/S HEX BOLT

4

5

94709A418

MCMASTER RUBBER+ STEEL WASHER 3/8

12

6

INSTALLER PROVIDED

M10 JAM NUT 316 S/S

4

7

INSTALLER PROVIDED

M10 HEX NUM 316 S/S

4

8

SHIP-SIDE MOUNT

TYPICAL SHIP-SIDE MOUNT

0

9

93925A290

MCMASTER LOCK WASHER M10

6

10

93635A424

MCMASTER M10-1.5X30 MACHINE SCREW

4

11

93635A416

MCMASTER M10X20MM HEX BOLT 316 SS

1

12

ANTI-SEIZE COMPOUND

LOCTITE 2.25 OZ STICK

1

6

D

C

B

A

E

F

G

H

E

A

B

C

D

F

5

4

3

2

1

7

8

9

10

11

12

1

2

3

4

5

6

7

8

G

9

10

11

H

PA6

1:2

UNITS

mm

MATERIAL

GEOMETRIC

TOLERANCING PER

ASME Y14.5m-1994

3D REFERENCE

A-ADA101_PA5

DOCUMENT NUMBER

D-ADA101_PA6

DESCRIPTION

ISSUE DATE

SIZE

A2

REVISION

SCALE

DRAWN BY

N.MAHER

0.10

2

0.15

HOLE TO HOLE

ANGULAR DIMENSIONS

LINEAR DIMENSIONS

TOLERANCES: UNLESS

OTHERWISE SPECIFIED

THIRD ANGLE

PROJECTION

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF IRIDIUM SATELLITE

LLC AND/OR ITS AFFILIATES AND LICENSORS, UNLESS OTHERWISE STATED. NEITHER THIS DRAWING

NOR ANY SUCH INFORMATION MAY BE COPIED, REPRODUCED, TRANSMITTED, DISTRIBUTED OR

OTHERWISE USED EXCEPT AS EXPRESSLY APPROVED IN WRITING BY IRIDIUM SATELLITE LLC AND/OR

ITS AFFILIATES. NO RIGHTS OR LICENSES OF ANY KIND TO SUCH DRAWING OR INFORMATION

(INCLUDING ANY INTELLECTUAL PROPERTY RIGHTS THEREIN) ARE TRANSFERRED TO, GRANTED TO,

PROVIDED TO OR RECEIVED BY THE RECIPIENT HEREOF AS A RESULT OF THE DELIVERY HEREOF. THIS

MATERIAL MAY NOT IN WHOLE OR IN PART BE COPIED, STORED ELECTRONICALLY OR

COMMUNICATED TO THIRD PARTIES WITHOUT THE PRIOR WRITTEN AGREEMENT OF IRIDIUM.

SHEET

1 of 1

PROPRIETARY AND CONFIDENTIAL

IRIDIUM PILOT SHIP MOUNT INSTRUCTIONS

10/31/2011

2. Fasten ADE radome to mounting bracket per “Radome mounting” steps above.

Note: Apply a thin coat of sealant between the base of the ADE mounting bracket.

CAUTION

Damage to the paint coating may allow rust to the ADE mounting bracket which could result

in failure of the ADE. This in turn could cause disruption in operation of the Iridium Pilot device.

Avoid damaging the paint coating. If damage occurs, re-apply appropriate anti-corrosion

primer and paint.

3. Install cable ties for strain relieve for the ADE/BDE cable and ground cable (earthing strap).

Note: Fit earthing strap between ADE grounding point and vessel superstructure.

Note: The mounting conguration may vary depending on the factors discussed (e.g.: location, pole selection).

When mounting the bracket ensure:

• The M10 bolts have 15 – 20 mm thread engagement into the ADE.

• ADE / BDE cable can be connected to the connector in the center of the ADE.

• Vent on ADE is not covered. It is also advisable to have labels visible after mounting.

The ADE provides a grounding connection for enhanced protection from lightning induced transients;

connection is not required in terms of user safety or protection of the ADE from the telephone network (as this

is provided in the BDE). The use of this connection must be considered as part of the overall grounding and

lightning protection scheme for the vessel as a whole.

www.busse-yachtshop.de | info@busse-yachtshop.de

Loading...

Loading...