ECI

MORTAR

SHIM IF REQUIRED

TO ACHIEVE

CORRECT HEIGH

14

Assembly Instructions - 28, 36, 42 & 48

FIGURE 8

General Isokern Assembly Instructions:

Earthcore Mortar (a thin-set type masonry adhesive)

is used to glue all Isokern components together during eld

assembly of the unit. The mortar is supplied dry, in either 15

pound or 50 pound pails.

Earthcore mortar is mixed with clean water to a

smooth, workable texture (without lumps or dry pockets)

of a “toothpaste” consistency. This mixture is suitable for

application onto Isokern components by using a masonry grout

bag supplied with the unit.

Attention should be paid that the mortar mixture is not

too thin or runny, as this will not allow the mortar to reach its

maximum bonding strength.

Earthcore mortar is squeezed from a grout bag onto

the contact surfaces of the Isokern components as they are tted

together.

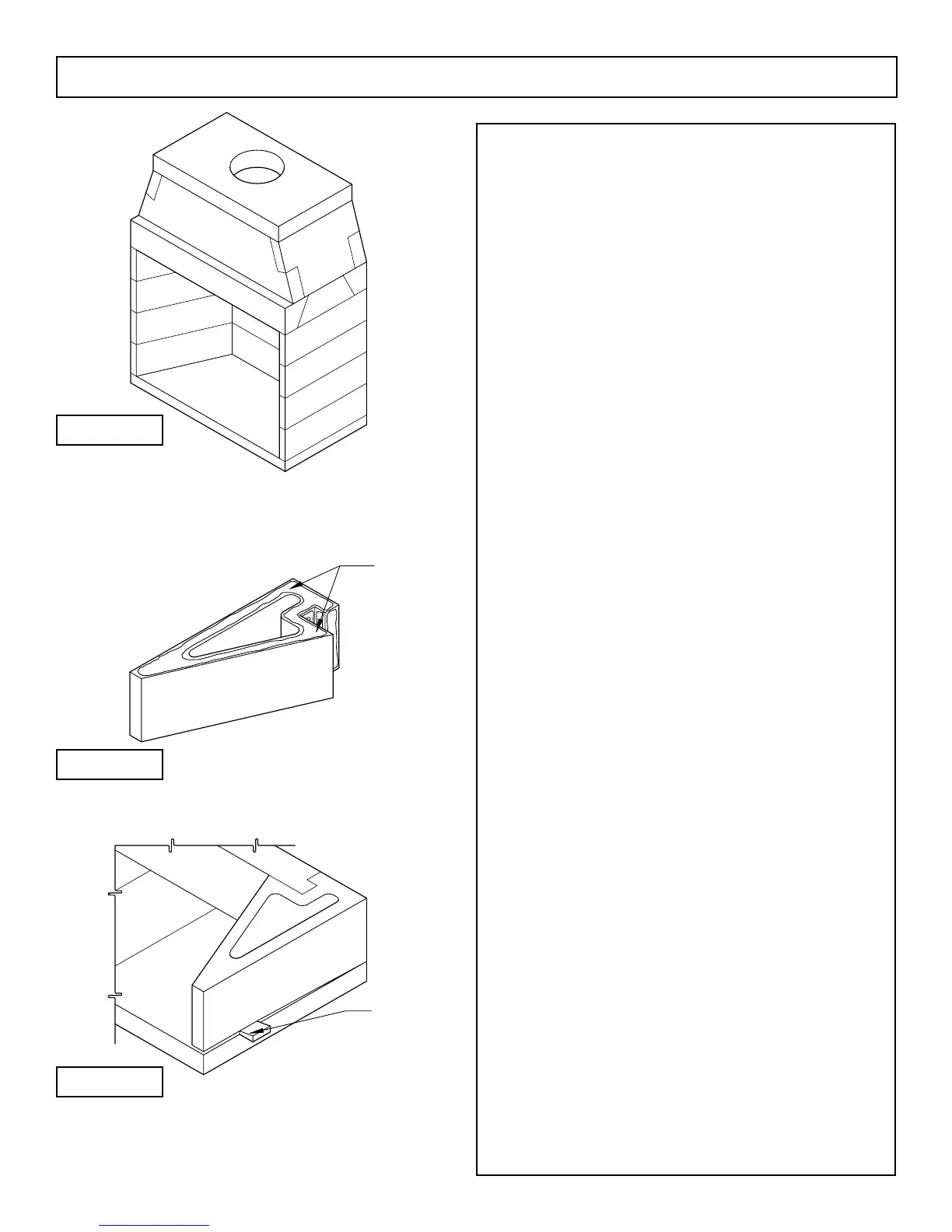

It is important that a 1/2” bead of mortar on all the

components’ contact surfaces is applied at about 1/2” in from

all edges of the contact surface of the component. (Figure 7)

When setting the next component onto the mortared

contact surface of the rst component, some mortar should

squeeze out along the face of the entire joint as a sign of

complete and proper sealing of the joint.

On broader contact surfaces it is advisable to apply

several additional 1/2” beads of the Earthcore Mortar to the area

to assure proper sealing of the joint.

Properly mortared rebox and smoke dome assembly

requires approximately 5 gallons (dry measure) of Earthcore

mortar.

Broken Components:

Components broken into 2 or 3 pieces can be repaired

by using Earthcore mortar along the break line as the component

is set into place. Components broken into multiple small pieces

should be discarded and replaced.

Leveling and Aligning Components:

Be sure to assemble all Isokern components level and

ush with adjoining components.

Earthcore mortar is not intended to create a mortar

joint of any thickness for leveling purposes. Therefore, leveling

and alignment adjustments are made by the use of small plastic

shims supplied with the unit. (Figure 8)

The shims can be inserted under a component to level

and align it with adjacent Isokern components. Be sure to re-

grout any and all gaps resulting from shim insertion to maintain

components to full bearing.

Notes:

1. Do not mix Earthcore mortar with spirits or anti-freeze

agents.

2. The maximum recommended mortar joint thickness at

Isokern components is 1/4”.

FIGURE 7

FIGURE 6

Loading...

Loading...