Page 13 of 40

Dual Furnace Models M17705, N17706 & 17707 Iss.09 – 12/14

COMMISSIONING

Connect the step down transformer to a suitable 230Vac supply.

Before connecting the unit to the mains power supply, check the impedance between live and earth, and neutral and

earth (values as low as 2MΩ on arrival are acceptable since moisture may be present after transportation).

Familiarise yourself with controller operation; manuals are supplied with all equipment.

Plug in and switch on the dual furnace (figure 1) and operate the reset button. This will energise the annealing

furnace controller. Adjust the set point to 100°C (450 and 500°C for potassium 17706 and Sodium 17705 models)

and the over-temperature controller set point to 50°C above the controller set point. After 1 or 2 hours the

annealing furnace will stabilise. Adjust its over-temperature set point downwards until the circuit relay trips,

switching off the annealing furnace.

Later models of the furnace use a Eurotherm over-temperature cut-off controller. On these models the RESET

button is located below the over-temperature controller. The SP value should be set approximately 50°C higher

than the operating controller setting. If this limit should be exceeded the red push button switch will reset the

apparatus once the furnace temperature has fallen below the AL1 value.

To turn on system power at start up (or as required), it is necessary to depress the red push button.

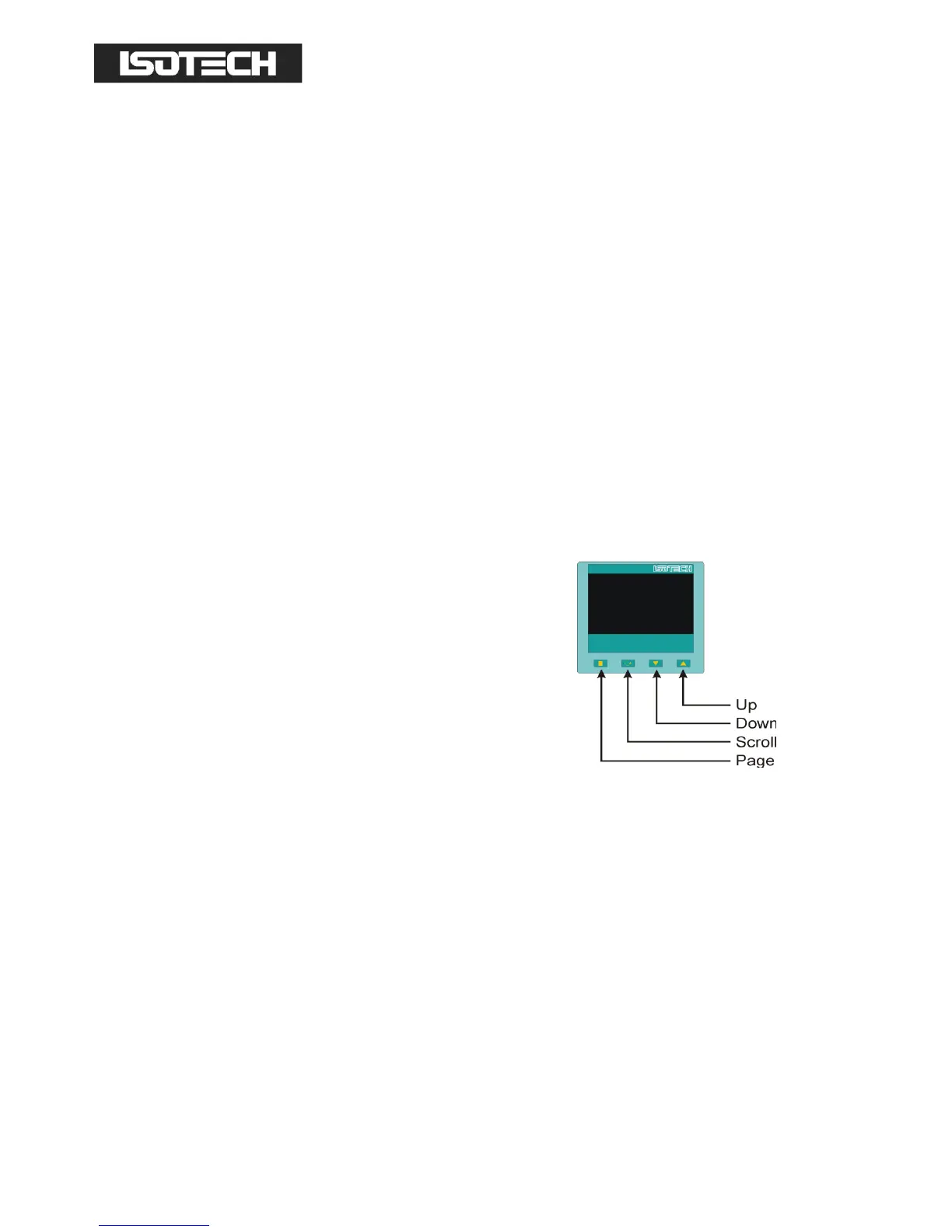

To adjust SP press the "Scroll" until the controller indicates “SP”.

Press the UP or DOWN keys to modify the SP value.

NOTE; the annealing/pre-heating furnace controller has been pre-set to produce a slow change in temperature, in

line with the heating and cooling rates recommended for annealing of thermometers. Do not over-ride the control

settings.

The recrystallised alumina liner has a closed end and thermometers may be placed directly into the liner for

annealing.

Switch on the main furnace (heat pipe) and press the reset button. This will energise the heater.

The rate of change of temperature for a heat-pipe at low temperature must be controlled, and for this reason the

heat-pipe controller has been pre-programmed to warm up slowly to its minimum working temperature. The

parameters used to effect this control are not directly accessible, for safety reasons.

As soon as the minimum temperature has been reached, the initial restriction on the rate of approach to set point is

removed.

The remainder of the instructions differ for the three models; reference should be made to the page clearly marked

with the appropriate dual furnace model.

Loading...

Loading...