6

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

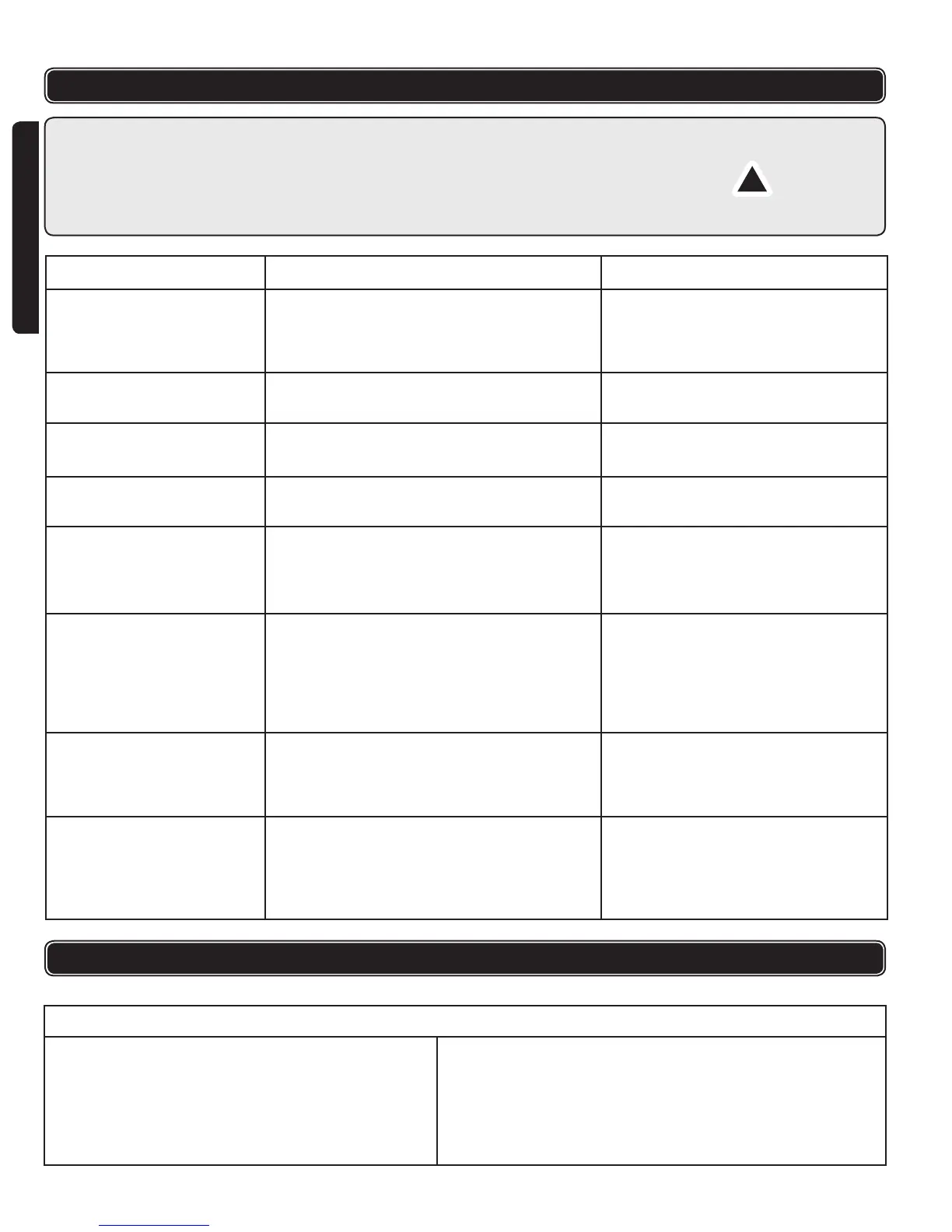

Air leak at trigger area O-ring in trigger valve damaged or cracked Check and replace O-ring

Trigger valve head damaged Check and replace trigger valve head

Trigger valve stem, seal or O-ring damaged Check and replace trigger valve stem,

seal or O-ring

Air leak between body and Piston O-ring or bumper damaged Check and replace O-ring or bumper

front plate

Air leak between body and Screw loose Tighten screws

cylinder cap Damaged seal Check & replace seal

Tool driving fasteners too Worn bumper Replace bumper

deeply Air pressure too high Adjust air pressure at regulator

Tool runs slowly or has power Insufcient lubrication Add oil as instructed

loss Insufcient air supply Check air supply

Broken spring in cylinder cap Replace spring

Exhaust port in cylinder head is blocked Replace damaged internal parts

Tool skips fasteners Worn bumper or damaged spring Replace bumper or pusher spring

Dirt in front plate Clean drive channel of front plate

Inadequate airow to tool Check hose and compressor ttings

Worn or dry O-ring on piston Replace O-ring or lubricate

Damaged O-ring on trigger valve Replace O-ring

Cylinder cap is leaking Replace seal

Fasteners jam in tool or Joint guide is worn Replace joint guide

magazine Fasteners are the wrong size or damaged Use only recommended fasteners

Magazine screws or front plate clamp are loose Tighten all

Blade in piston assembly is damaged Replace piston assembly

Tool will not drive fasteners Worn blade in piston assembly Replace piston assembly

down tight Lack of power Adjust regulator to adequate pressure

Slow cycling and loss of power Check cylinder cap spring for broken

coils, reduced length or if exhaust port

is blocked

PROBLEM

SOLUTIONCAUSE

TROUBLESHOOTING

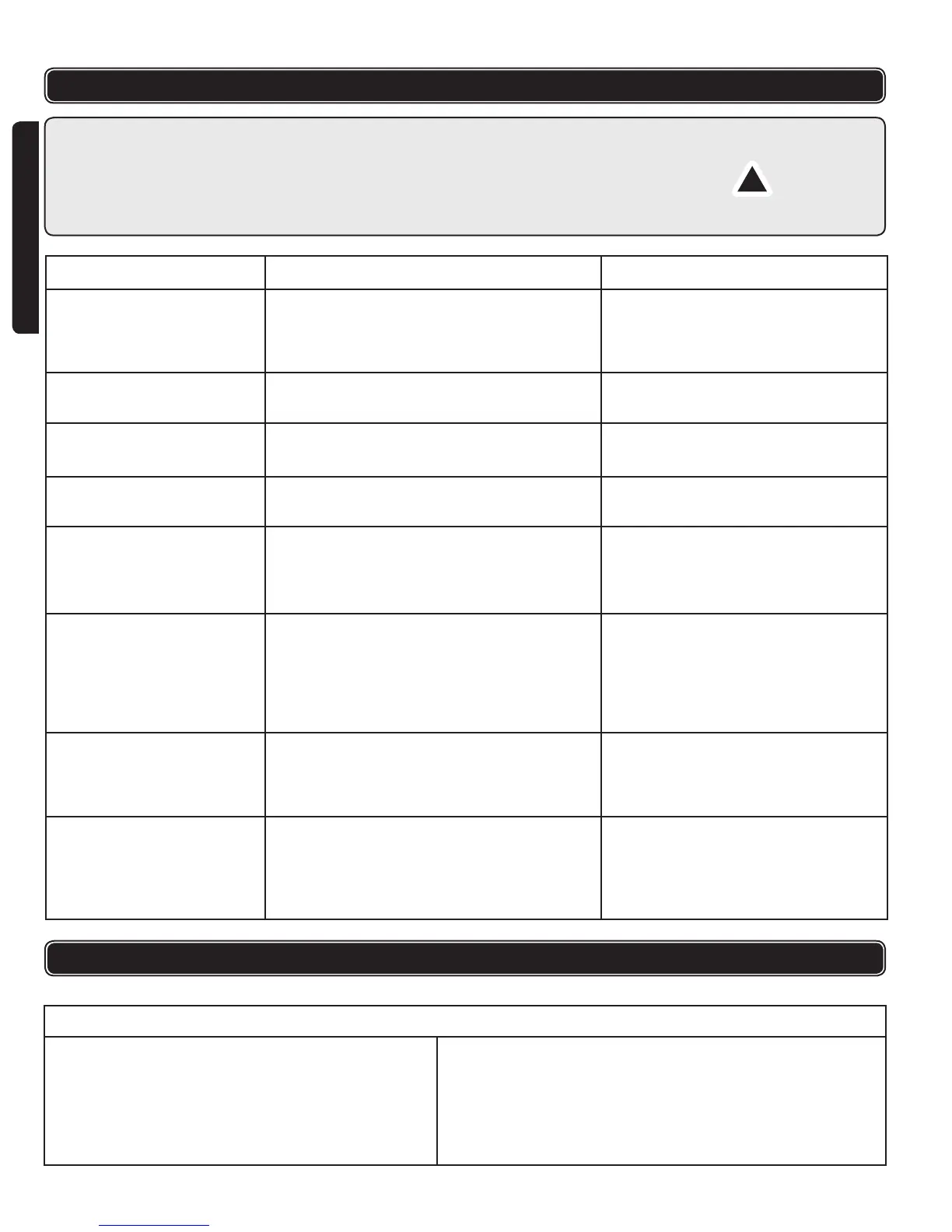

PARTS LIST

PART NO. DESCRIPTION PART NO. DESCRIPTION

1 Screw 36 Spring pin

2 Bushing 37 Pin

3 Exhaust cover 38 Lock washer

4 Seal 39 Trigger

5 Screw 40 Spring pin

6 Cylinder cap 41 Plate

7 Gasket 42 Screw

Please refer to schematic drawing page 15

STOP using the tool immediately if any of the following problems occur. Serious

personal injury could occur. Any repairs or replacements must be done by a

qualiedpersonoranauthorizedservicecentreonly.

CAUTION: Disconnect the tool from air supply before performing any service

procedure. When inserting new or re-installing O-rings, make sure they are

clean and lubricated with an O-ring lubricant.

Loading...

Loading...