Do you have a question about the ITT Goulds Pumps 3755 and is the answer not in the manual?

Provides crucial safety information for users to minimize injury risk during operation.

Highlights significant risks associated with pumping equipment operation and potential hazards.

Defines terms like Warning, Caution, and Electrical Hazard, and outlines associated risks.

Details essential safety measures for operating and maintaining the pump to prevent injury.

Addresses ATEX directives for explosive environments and guidelines for safe operation.

Details on identifying ATEX-certified equipment and the importance of genuine Goulds parts.

Guidelines for selecting an appropriate and accessible location for the pumping unit.

Instructions on creating a substantial and rigid foundation for the pumping unit.

Procedures for achieving initial alignment between the pump and driver shafts.

Steps for connecting suction and discharge piping and rechecking alignment.

Ensuring the driver rotates in the correct direction for the pump.

Instructions for connecting the pump and driver coupling.

Details on lubricating grease and oil lubricated pump bearings, including oiler settings.

Ensuring the driver bearings are properly lubricated for reliable operation.

Instructions for repacking stuffing boxes with packing rings or managing mechanical seals.

Connecting sealing liquid, quenching glands, and cooling water piping as required.

Connecting drain piping for the pump's drip pockets and drip basin.

Ensuring the pump is fully primed with liquid and all air removed before starting.

How to adjust the stuffing box gland while the pump is running for proper leakage.

Performing final alignment checks after the unit reaches operating temperature.

Information on doweling, noting that patented lock washers are used instead.

Operational checks and adjustments for stuffing boxes with packing rings, quenching glands, and mechanical seals.

Precautions against operating the pump at very low capacities to prevent overheating and damage.

Monitoring motor heating when operating at significantly reduced discharge head.

Addressing potential pressure surges in the discharge line and necessary cushioning arrangements.

Procedure for draining the pump to prevent damage during freezing conditions when idle.

Identifies causes and solutions for the pump not delivering any liquid.

Lists potential reasons and remedies for the pump delivering less liquid than expected.

Diagnoses issues related to the pump not achieving the required discharge pressure.

Addresses scenarios where the pump operates briefly then stops unexpectedly.

Identifies causes for the pump consuming more power than normal.

Explains reasons for excessive leakage from the pump's stuffing box.

Diagnoses causes of pump noise and vibration, including hydraulic and mechanical issues.

Detailed instructions for lubricating grease and oil lubricated bearings, including frequency and type.

Step-by-step guide for removing old packing and installing new packing in the stuffing box.

Procedure for removing and installing a new shaft sleeve to ensure proper sealing.

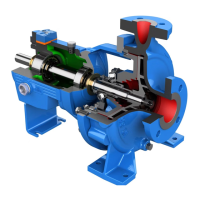

Explanation of wearing rings and their importance for hydraulic performance and clearances.

Procedure for replacing grease lubricated bearings, including disassembly and reassembly steps.

Procedure for replacing oil lubricated bearings, noting specific steps and differences.

Steps for correctly locating and installing the impeller on the shaft, referencing specific tables and figures.

Specific steps for replacing the casing when the pump uses oil lubricated bearings.

Step-by-step instructions for replacing the pump casing, covering general configurations.

Advice on maintaining a stock of spare parts to minimize downtime.

Guidance on how to correctly place orders for replacement parts.

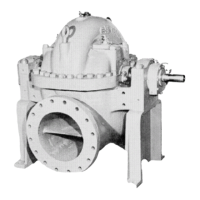

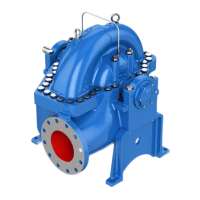

| Model | 3755 |

|---|---|

| Category | Water Pump |

| Manufacturer | ITT Goulds Pumps |

| Type | Centrifugal |

| Casing Material | Cast Iron |

| Maximum Flow Rate | 1500 GPM |

| Maximum Head | 150 ft |

| Impeller Diameter | Varies with model |

| Speed | 1750 RPM or 3500 RPM |

| Material | Cast Iron, Stainless Steel |

| Seal Type | Mechanical Seal |

| Weight | Varies by model |