Do you have a question about the ITT Goulds Pumps 3405 and is the answer not in the manual?

User safety is a major focus. Precautions minimize risk of injury.

Risks specific to pumping equipment require reinforcement beyond normal safety.

General safety measures and precautions for installation and operation.

Definitions of WARNING, CAUTION, ELECTRICAL, and ATEX terms.

Special care for explosive environments & intended operational use.

Information on genuine Goulds parts for reliable operation.

Proper placement for access, inspection, and maintenance.

Requirements for a substantial and rigid foundation support.

Steps for achieving initial pump and driver alignment.

Guidelines for proper piping support and configuration.

Proper installation of suction piping for trouble-free pump operation.

Recommended installation of discharge piping with valves.

Connecting suction and discharge piping, checking for binding.

Verifying correct driver rotation direction.

Connecting pump and driver coupling per manufacturer's instructions.

Connecting water piping for bearing cooling on specific models.

Connecting overflow outlets for drains.

Lubrication and type of bearings used for different models.

Checking driver bearings and coupling lubrication.

Information on packed stuffing boxes and mechanical seals.

Connecting water seal piping for specific operating conditions.

Connecting piping for quenching glands on specific applications.

Detailed instructions for connecting bearing cooling water piping.

Connecting overflow outlets from stuffing boxes and bedplate.

Methods and procedures for priming the pump before starting.

Regulating water flow to cooled bearings and glands.

Adjusting stuffing box glands while the pump is running.

Final alignment check after the unit reaches operating temperature.

Doweling procedure for specific pump groups for final alignment.

Periodic inspection and maintenance of stuffing boxes.

Hazards of operating at reduced capacities or closed discharge.

Monitoring motor heating when operating at reduced head.

Precautions for preventing pressure surges in the discharge line.

Procedures for draining pump and cooling water in freezing conditions.

Common causes and checks for no water delivery.

Common causes and checks for insufficient water delivery.

Common causes for insufficient discharge pressure.

Potential reasons for the pump stopping after a period of operation.

Causes for excessive power consumption by the pump.

Reasons for excessive leakage from the stuffing box.

Causes of mechanical or hydraulic noise in the pump.

Procedures for removing and repacking stuffing boxes.

Instructions for greasing and oiling pump bearings.

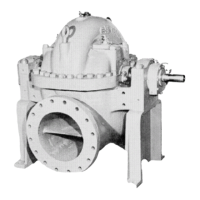

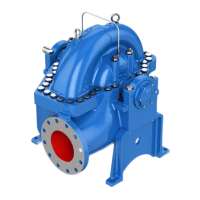

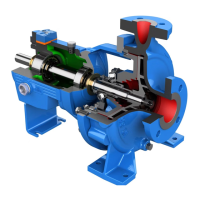

Detailed sectional views of pump components for reference.

Step-by-step instructions for disassembling the pump.

Step-by-step instructions for reassembling the pump.

Checks for wear and clearances during pump overhaul.

Procedures for changing the pump's direction of rotation.

Procedure for replacing a thrust end ball bearing in an emergency.

Recommended spare parts for maintenance and stocking.

Guidelines for ordering replacement parts correctly.

| Brand | ITT |

|---|---|

| Model | Goulds Pumps 3405 |

| Category | Water Pump |

| Language | English |