Do you have a question about the ITT Goulds Pumps 3415 and is the answer not in the manual?

Key safety information for users to minimize injury risks.

Reinforces significant risks beyond normal safety precautions for pumping equipment.

Defines terms and details specific hazards like electrical and ATEX risks.

Provides essential safety measures and precautions for operating and maintaining the pump.

Explains ATEX directives for equipment in potentially explosive atmospheres.

Outlines requirements for operating within intended use and compliance with ATEX standards.

Illustrates a typical ATEX nameplate and explains its components.

Details the temperature class definitions relevant to ATEX compliance.

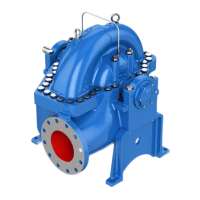

Procedures for proper storage, uncrating, and handling of the pump unit.

Guidelines for selecting an appropriate location for the pumping unit.

Specific installation instructions for close-coupled and vertical pump types.

Detailed steps for installing horizontal split case and bedplate mounted pumps.

Importance and general steps for initial pump and driver alignment.

Methods for achieving parallel shaft alignment based on pump type and operating temperature.

Best practices for piping support, connection, and preventing strain on the pump.

Critical guidelines for designing and installing effective suction piping.

Guidance on gate and check valves, and handling of quick-closing valves.

Steps for connecting suction and discharge piping to the pump.

Crucial step of checking and ensuring correct pump rotation direction.

Instructions for connecting the pump and driver coupling.

Detailed guidance on oil and grease lubrication for pump bearings.

Ensuring proper lubrication of driver bearings and coupling.

Procedures for packing stuffing boxes, including types of packing and installation.

Connecting sealing liquid or grease lubricators for packed boxes.

Connecting cooling water lines for quench glands, bearings, stuffing boxes, and mechanical seals.

Connecting drain piping for stuffing boxes.

Connecting equalizing piping for multi-stage pumps.

Procedures for adjusting impeller clearance to prevent damage.

Verifying that the rotating element turns freely before starting.

Regulating flow rates for cooling and flushing liquids to various components.

Methods for priming the pump before starting.

Adjusting stuffing box packing and observing leakage after startup.

Verifying proper operation and checks for mechanical seals after startup.

Performing final alignment checks after the unit has reached operating temperature.

Instructions for doweling the pump and driver to the foundation for stability.

How to operate and maintain stuffing boxes with packing or mechanical seals.

Warnings and precautions for operating the pump at reduced capacities or closed discharge.

Considerations for operating the pump with reduced head and potential motor heating.

How to handle surge conditions in the discharge line to prevent damage.

Procedures for protecting the pump during freezing conditions.

Detailed instructions for oil and grease lubrication of bearings.

Procedures for adjusting impeller clearance.

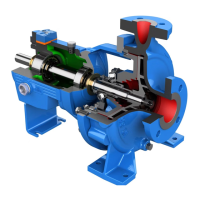

Step-by-step guide for disassembling the pump.

Chart and explanation for determining pump pressure and temperature limits.

Inspecting and replacing O-rings and wearing rings for optimal performance.

Steps for replacing impeller wearing rings and related clearance specifications.

Proper installation of gaskets to ensure sealing and prevent leakage.

Checking shaft straightness and impeller condition during reassembly.

Procedures for replacing an outboard end ball bearing without a full overhaul.

Monitoring and understanding normal bearing operating temperatures.

Methods for inspecting ball and roller bearings for wear.

Procedures for cleaning bearings if necessary, emphasizing dust-free environments.

Techniques for safely removing ball and sleeve bearings.

Steps for correctly installing ball bearings onto the shaft.

Troubleshooting steps for when the pump fails to deliver liquid.

Diagnosing issues when the pump delivers insufficient water.

Troubleshooting pump issues related to insufficient discharge pressure.

Identifying causes for the pump stopping after initial operation.

Diagnosing issues causing excessive power consumption by the pump.

Troubleshooting excessive leakage from the stuffing box.

Identifying the causes of pump noise and vibration.

Troubleshooting high bearing temperatures.

Recommended spare parts inventory for different pump types.

Essential information needed for placing spare parts orders.

Visual representation and list of all pump parts with identification numbers.

Contact information for local ITT Goulds Pumps representatives.

| Brand | ITT |

|---|---|

| Model | Goulds Pumps 3415 |

| Category | Water Pump |

| Language | English |