Do you have a question about the ITT GOULDS PUMPS LF 3196 i-FRAME and is the answer not in the manual?

| Model | LF 3196 i-FRAME |

|---|---|

| Category | Water Pump |

| Manufacturer | ITT Goulds Pumps |

| Type | Centrifugal Pump |

| Material | Stainless Steel |

| Application | Industrial |

Provides an overview of the manual's purpose and scope.

Covers critical safety warnings, terminology, and precautions for operation.

Details the terms, coverage, and limitations of the product warranty.

Addresses safety regulations and considerations for equipment in potentially explosive atmospheres.

Instructions for inspecting the pump unit upon arrival for any damage or missing items.

Guidelines and methods for safely handling and lifting the pump during transport.

Requirements for proper short-term and long-term storage to preserve the pump's condition.

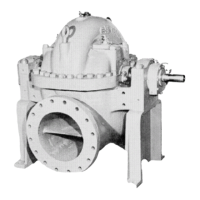

Overview of the LF 3196 pump, its type, and design characteristics.

Description of the i-ALERT®2 monitor, its function, and features for pump monitoring.

Explains the importance of nameplate data for ordering parts and identifying pump specifications.

Precautions and guidelines for selecting the pump location and preparing the foundation.

Detailed procedures for preparing, installing, and leveling the baseplate using various methods.

Steps for mounting and fastening the pump, driver, and coupling onto the baseplate.

Critical procedures for ensuring proper pump and driver alignment to prevent damage.

Procedures and requirements for grouting the baseplate to ensure stability and alignment.

Checklists for ensuring correct suction and discharge piping installation to prevent issues.

Essential precautions and checks to perform before starting the pump for the first time.

Steps for safely removing the coupling guard before accessing the coupling for maintenance.

Procedure to verify the correct direction of pump rotation before initial startup.

Detailed procedures for setting impeller clearance using dial indicator or feeler gauge methods.

Guidelines for properly coupling the pump and driver, including installing the coupling guard.

Methods for priming the pump to ensure it is filled with liquid before startup.

Critical steps and warnings for starting the pump and monitoring its initial operation.

Safe procedures for shutting down the pump, including closing valves and locking out the driver.

Outlines routine, three-month, and annual inspections to ensure pump reliability.

Comprehensive guide to lubricating, regreasing, and maintaining pump bearings.

Maintenance procedures for mechanical seals and packed stuffing boxes to ensure sealing integrity.

Detailed steps and precautions for safely disassembling the pump for maintenance or repair.

Guidelines for inspecting pump parts before reassembly to ensure proper condition.

Comprehensive instructions for reassembling the pump components after maintenance.

Common operational problems, their causes, and recommended remedies for pump issues.

Solutions for issues related to achieving proper horizontal (side-to-side) alignment.

Troubleshooting steps for common problems encountered during pump assembly and reassembly.

Comprehensive list of pump parts with their material codes and quantities for various models.

Information on how to obtain further relevant documentation or manuals from ITT.

Contact information for ITT regional offices worldwide for support and inquiries.