it

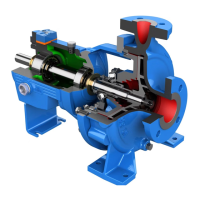

GRUPPI DI PRESSIONE

ANTINCENDIO SERIE GEN

Istruzioni d’installazione e uso

en

GEN SERIES FIREFIGHTING

BOOSTER SETS

Installation and Operating Instructions

fi

GEN-PALOTORJUNTASARJAN

PAINEYKSIKÖT

Asennus- ja käyttöohjeet

pt

UNIDADES DE PRESSURIZAÇÃO

ANTI-INCÊNDIO SÉRIE GEN

Instruções de instalação e uso

it

Conservate con cura il manuale per future consultazioni

en

Keep this manual for future reference

fi

Säilytä käyttöopas huolellisesti

pt

Conservar cuidadosamente o manual para consultas futuras

Lowara

cod. 001073667 B 03/08