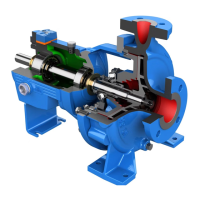

What to do if the runout for the impeller wear ring is excessive in my ITT Goulds Pumps XHD Water Pump?

- DDustin HarperSep 19, 2025

If the runout for the impeller wear ring is excessive in your ITT Water Pump, the shaft may be bent and needs replacement. Alternatively, the wear ring may have been machined improperly, requiring replacement or re-machining of the impeller.