5.10.1 Lubricate the bearings with oil

WARNING:

Risk of explosive hazard and premature failure from sparks and heat generation.

Ensure bearings are properly lubricated prior to startup.

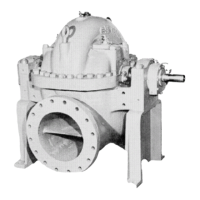

1. Remove the oil fill pipe plug (319B).

2.

Fill the bearing frame with oil through the filler connection that is located on the top of the bearing

frame.

3. Fill the bearing frame with oil until the oil level reaches the middle of the sight glass or opposite

sight glass (319 or 408N). The correct volume of oil required for each size of bearing frame can be

found in the ‘Oil Volume Requirements’ section in the ‘Bearing Maintenance’ / ‘Maintenance’ portion

of the IOM.

319B

319 and

408N

(opposite side)

1

1. Correct level

Figure 38: Oil lubricated bearings

4.

Replace the oil fill pipe plug (319B).

5.11 Shaft-sealing options

In most cases, the manufacturer seals the shaft before shipping the pump. If your pump does not have a

sealed shaft, see the Shaft-seal maintenance section in the Maintenance chapter.

NOTICE:

The mechanical seal used in an ATEX classified environment must be properly cer-

tified.

The mechanical seal must have an appropriate seal-flush system. Failure to do so

will result in excess heat generation and seal failure.

This model uses these types of shaft seals:

•

Cartridge mechanical seal

• Packed-stuffing-box option

5.11 Shaft-sealing options

60 XHD Installation, Operation, and Maintenance Manual

Loading...

Loading...