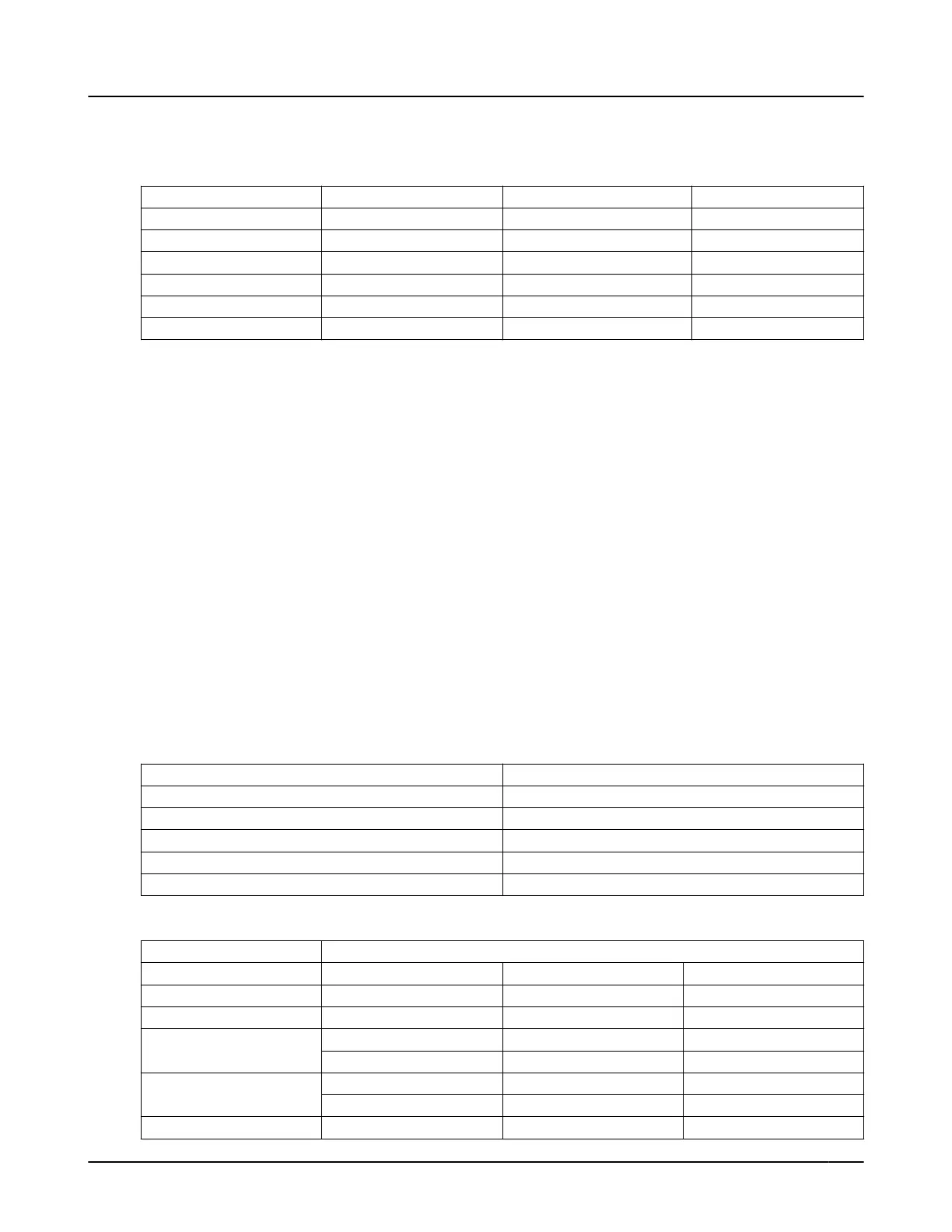

6.1.3 Oil volumes

Oil volume requirements

Frame Milliliters Quarts Ounces

PF1 1040 1.1 35

PF2 1400 1.5 48

PF3 1600 1.7 54

PF4S 2630 2.78 89

PF4 3975 4.2 134

PF5 4600 4.9 157

6.1.4 Acceptable oil for lubricating bearings

Acceptable lubricants

Use a high quality turbine oil with rust and oxidation inhibitors.

Oil ISO viscosity recommendations can vary based on Operating speed, Ambient temperature and Ro-

tating element loading.

The following recommendations for oil viscosity will suit a variety of XHD product applications. Due to

variables during operation such as operational speed, SG of liquid being pumped, ambient temperature,

bearing setting preload and other factors, the tapered roller bearings used on XHD products can routine-

ly operate at temperatures as high as 99°C | 210°F

. As a general rule, oil temperature above 102°C |

215°F should be avoided, except during initial break in of new equipment. In no case should bearings

ever operated above 121°C | 250°F for any period of time.

In the event of excessive bearing temperatures as defined above, monitor bearing and oil temperature to

confirm then investigate the root cause. Bearing preload, and improper assembly are possible causes.

Confirm bearing preload (End cover shimming) for correct assembly per the procedure outlined in the as-

sembly section of this IOM. Based on Ambient temperature, operating speed, and application variables

(SG / temp) a different oil viscosity may be selected for the application.

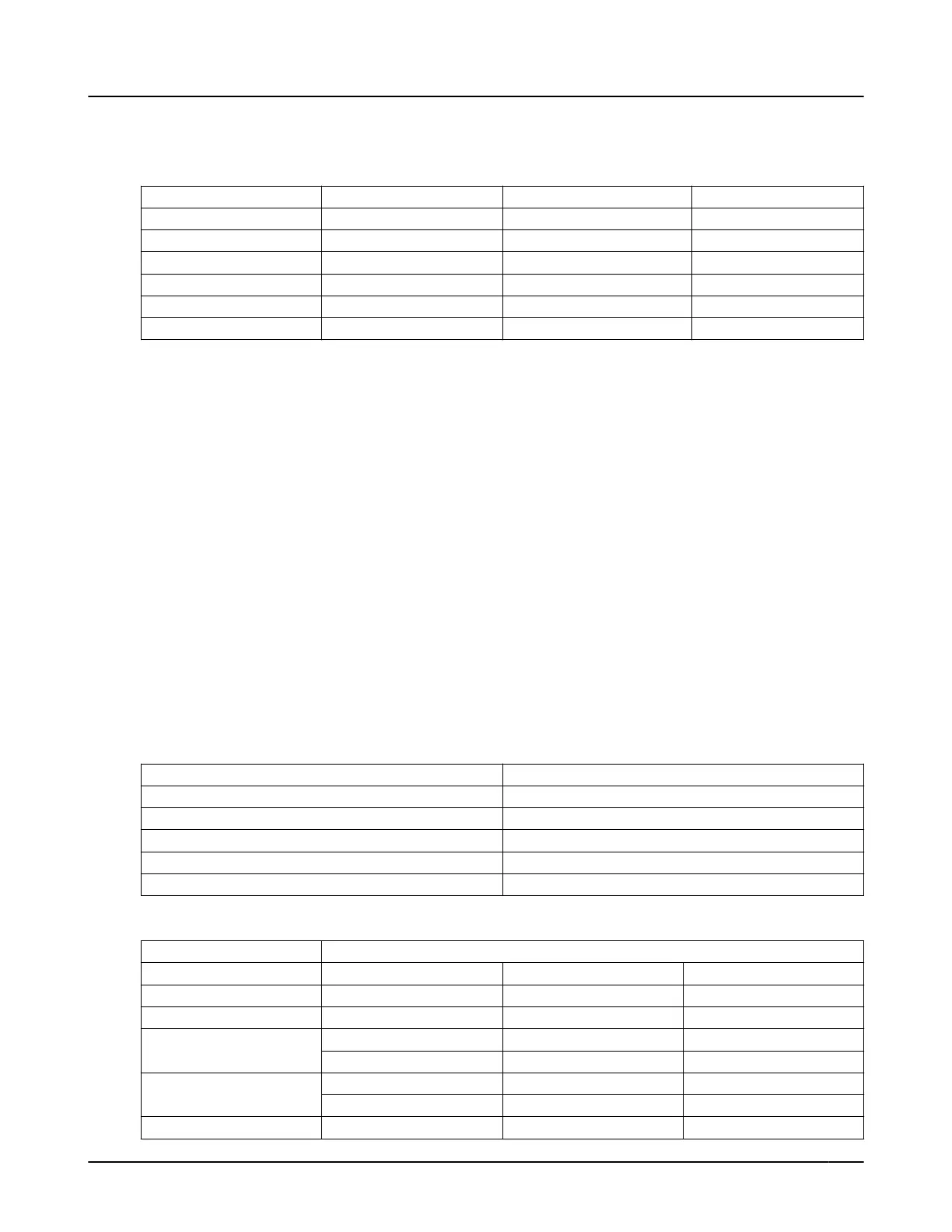

Table 13: Frame Designation Oil Viscosity (General Recommendation)

Frame Designation Oil Viscosity

PF1 100

PF2 100

PF3 100

PF4 / PF4S 150

PF5 220

Table 14:

Brand Lubricant Type

Castrol Hyspin R&O 220 Hyspin R&O 150 Hyspin R&O 100

Chevron GST 220 GST ISO 150 GST ISO 100

Exxon Teresstic 220 Teresstic 150 Teresstic 100

Mobil DTE Oil BB - - - VG100

Gear 630 Gear 150 Gear 627

Shell Morlina 220 Morlina 150 Morlina 100

Tellus 220 - - - Tellus 100

Sunoco Sunvis 9220 Sunvis 9150 Sunvis 9100

6.1 Maintenance schedule

XHD Installation, Operation, and Maintenance Manual 77

Loading...

Loading...