5.11.1 Mechanical seal options

Pumps are usually shipped with mechanical seals installed. If they are not, then refer to the mechanical

seal manufacturer's installation instructions.

These are the mechanical seal options for this pump:

•

Cartridge mechanical seal

5.11.2 Connection of sealing liquid for mechanical seals

Seal lubrication is required

Seal faces must have liquid film between them for proper lubrication. Locate the taps using the illustra-

tions shipped with the seal.

If a flushless slurry seal was ordered, then consult manufacturers instructions for seal lubrication.

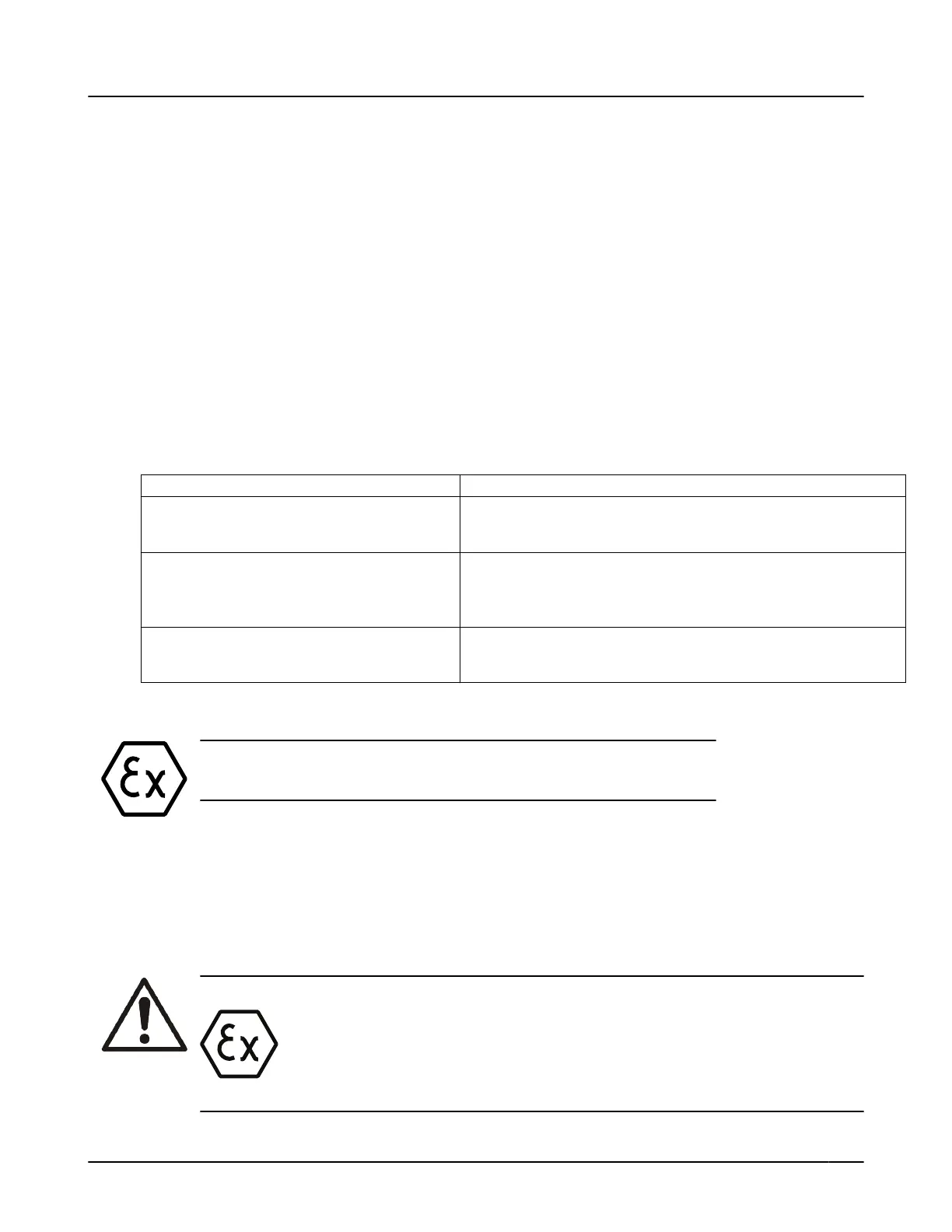

Seal flushing methods

Table 11: You can use these methods in order to flush or cool the seal:

Method Description

Product flush Run the piping so that the pump pushes the pumped fluid from the

casing and injects it into the seal gland. If necessary

, an external heat

exchanger cools the pumped fluid before it enters the seal gland.

External flush Run the piping so that the pump injects a clean, cool, compatible liquid

directly into the seal gland. The pressure of the flushing liquid must be

0.35 to 1.01 kg/cm

2

| 5 to 15 psi greater than the seal chamber pres-

sure. The injection rate must be 2 to 8 lpm | 0.5 to 2 gpm.

Other You can use other methods that employ multiple gland or seal cham-

ber connections. Refer to the mechanical seal reference drawing and

seal flush/cooling piping diagrams.

5.11.3 Packed stuffing box option

WARNING:

Packed stuf

fing boxes are not allowed in an ATEX-classified environment.

The factory does not install the packing, lantern ring, or split gland.

These parts are included with the pump in the box of fittings. Before you start the pump, you must install

the packing, lantern ring, and split gland according to the Packed stuf

fing box maintenance section in the

Maintenance chapter.

5.11.4 Connection of sealing liquid for a packed stuffing box

WARNING:

The mechanical seal must have an appropriate seal-flush system. Failure to do so

will result in excess heat generation and seal failure.

5.11 Shaft-sealing options

XHD Installation, Operation, and Maintenance Manual 61

Loading...

Loading...