The double mechanical seals fitted to

Hy~Line and Ultima provide the facility to

contain a high pressure fluid behind the

primary seal. This allows the pump to be

used for applications where the single seal

is unsuitable. Double seals Codes 1 and 4

are run with a fluid between the primary and

secondary mechanical seals to form a

barrier between the pump and the

atmosphere.

For LH32 and LH34 Pumps:

Double mechanical shaft seals are not

available on the LH32 or LH34 size pumps.

They are used with:

Double Mechanical Seal with a low

pressure liquid flush when:

• The pumped fluid is toxic or hazardous

and must not escape from pump even in

minute quantities.

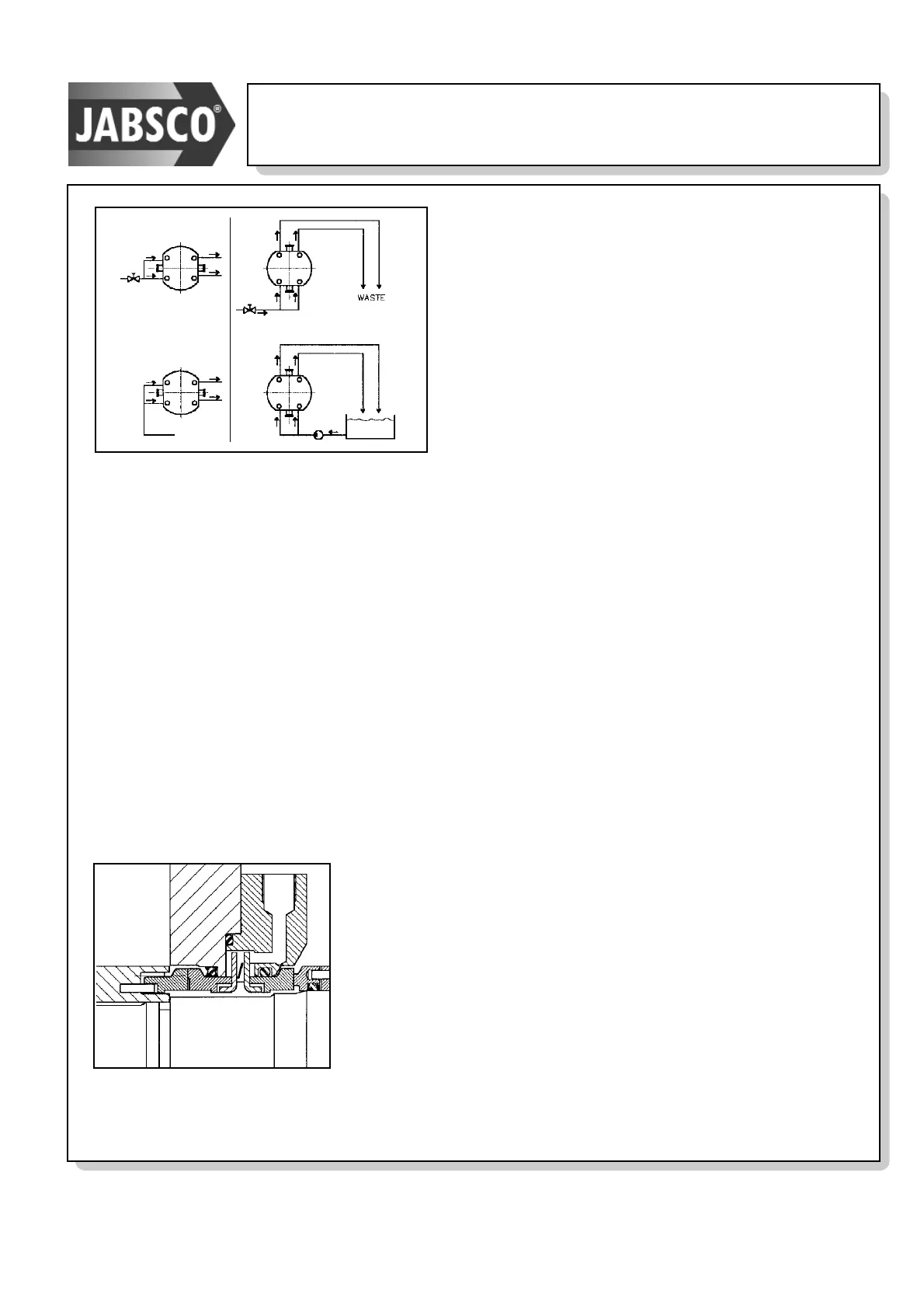

• The system can be installed as in figure

4a but must be capable of withstanding

the full pressure within the pumped fluid

pipe system.

Double Mechanical Seal with a high

pressure liquid flush when:

• The pumped fluid has no lubricating

properties and cannot be allowed onto

seal faces

• Pumped fluid is highly viscous, i.e. over

150,000 cps.

• A high pressure sterile liquid barrier is

required.

When the double seal is used with a high-

pressure liquid flush for the reasons

described above, a flushing system must be

installed as follows:

• The flushing liquid used must itself be

compatible with the pumped fluid and

must itself not require a complex seal, i.e.

must be non hazardous, non abrasive and

lubricating.

• Flush liquid must be at a pressure of 1 bar

(15psi) above the discharge pressure of

the Jabsco lobe pump and should flow at

35 to 55 litres/hour (10 to 15 US gal/hour)

per seal.

Page 11

Hy~Line and Ultima Lobe Pumps

07/03

Figure 4a: Suggested Low Pressure

Flushing System

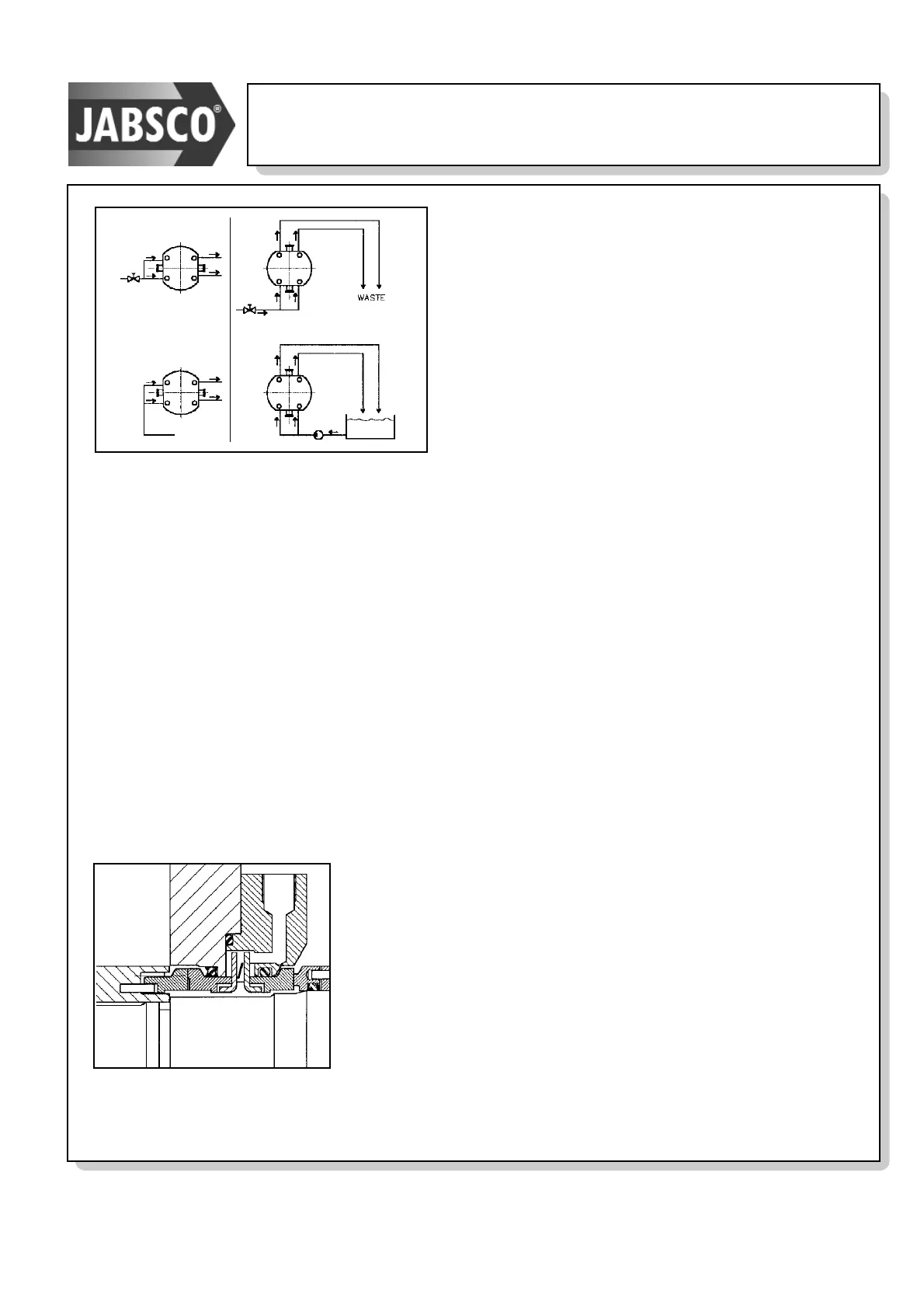

Figure 5:

Double

Mechanical

Seal

Loading...

Loading...