4. START UP & ROUTINE

CHECKS

4.01 START UP

Before starting pump for the first time or

after servicing or maintenance work, check

the following - failure to do so could damage

equipment or cause injury to personnel.

• All pump head and mounting bolts are

tight.

• All pipe connections are secure.

• All guards, safety and protection devices,

are in place and effective.

• Flushing fluid, if required, is flowing - see

Section 2.10.

• All valves are open - NEVER run pump

against a closed valve.

• Pipes and pump head, if heated, are to

normal operating temperature.

• Pump and pipes are clear of welding flash

or other debris.

NEVER use Hy~Line or Ultima pumps

to flush the system the first time. Flush

the whole system with suitable cleaning

agents before starting the Hy~Line or

Ultima pump, using another more

suitable pump if necessary. Be aware

that heavy or metal debris tends to

collect at the lowest point in the system.

• Pump is correctly lubricated - see

Section 3.

• Motor is wired for correct direction of

rotation - see Figure 9.

When possible, start pump slowly and

increase speed gradually.

• Listen for unexpected noises.

• Check for leaks.

• Check that pump gives desired flow rate

at normal operating speed.

• Do not continue to run pump if fluid is not

flowing; dry running can damage seals -

see Section 2.10.

• Observe pump during first few hours of

operation - check for noises and

excessive heating of pump bearing

housing, i.e. if above 80°C (176°F), unless

pumping hot liquids when 110°C (230°F)

may be reached.

• If operating at high speeds or with hot

liquids, surface temperatures can exceed

50°C (122°F), safety labels may be

required to comply with local safety

regulations.

Page 16

Hy~Line and Ultima Lobe Pumps

07/03

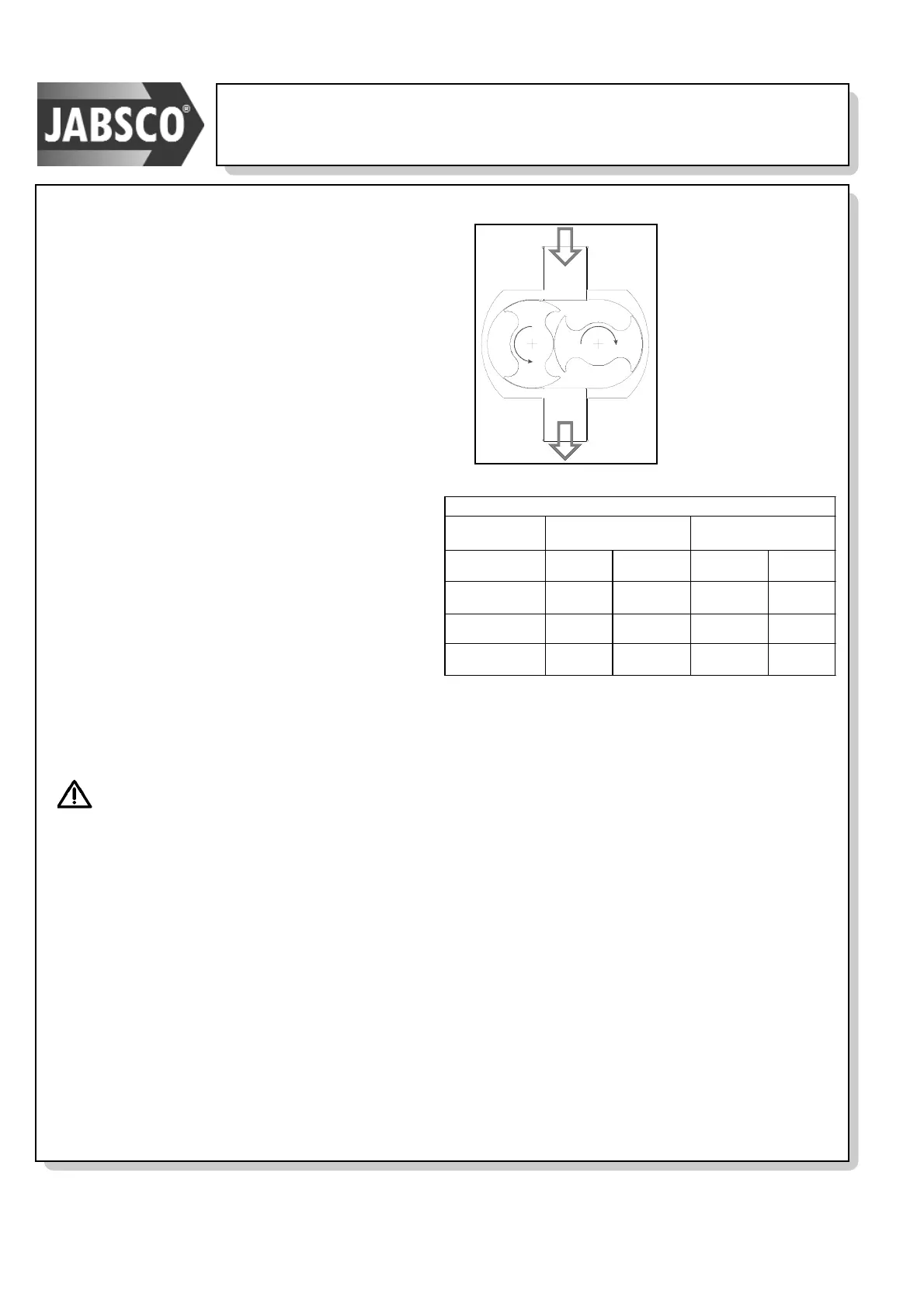

Figure 9.

Direction of

rotation -

viewed from

pump head.

(Principles

applies to all

mounting

orientations)

Loading...

Loading...