MAINTENANCE & LUBRICATION CHARTS 6

33

6 MAINTENANCE & LUBRICATION CHARTS

6.1 GENERAL ________________________________________________________________

1. Always clean grease fittings before and after lubrication.

2. Lubricate with grease that meets or exceeds NLGI

Grade 2 LB specifications. Apply grease with a manual

grease gun and fill slowly until grease begins to seep

out. Do not use compressed air.

3. For smooth operation of pivot points and other friction

points, apply several drops of SAE 30 oil every 50

hours or as required.

4. Remove wheels and repack bearings once a year.

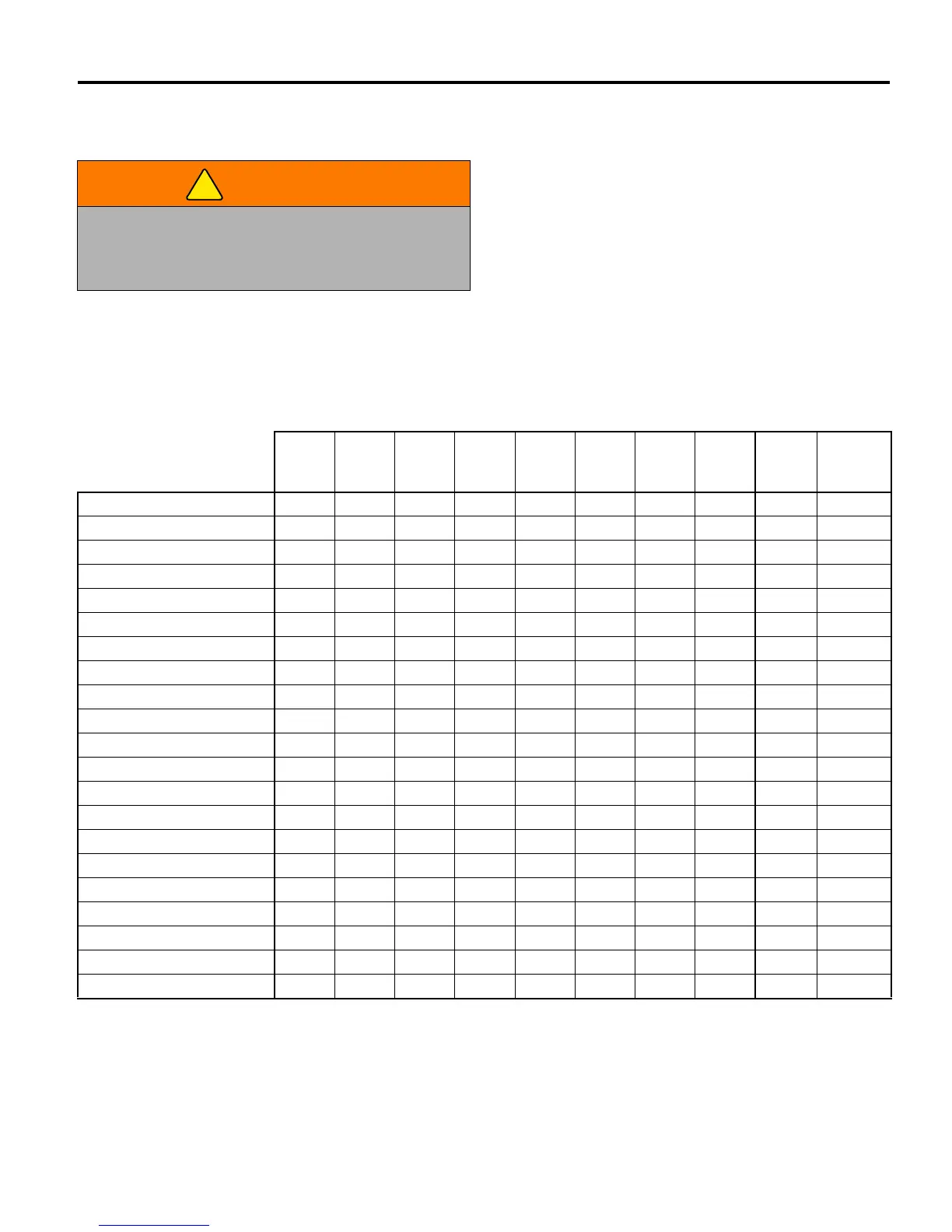

6.2 MAINTENANCE CHART_____________________________________________________

A - Add or Adjust C - Clean I - Inspect L- Lubricate R - Replace AR - As Required

* Indicates initial service for new machines.

** Or Yearly whichever comes first. *** Inspect visible hoses and tubes for leaks or oil marks.

I Pack bearings with NLGI Grade 2 (Service Class GB)

II Manual grease gun with NLGI Grade 2 (Service Class LB).

III Engine Oil - See Section 7.3

IV Jacobsen Hydraulic Oil - SAE 10W30 or Greens Care 68

WARNING

Before you clean, adjust, or repair this equipment,

disengage all drives, lower implements to the ground,

engage parking brake, stop engine, and remove key

from ignition switch to prevent injuries.

Loading...

Loading...