Instruction Manual FS140 and FS100 - 6115... / 6116...

© BA_FS140+100_EN_Rev02-2010.doc Page 10 of 20

6.2 Drive with electric motor

Electrical work must be carried out by trained electricians.

Check the electric motor drive unit. If it runs noisily, replace the ball bearing between the gear unit and

the spindle if necessary.

Lubricate the spindle with chain grease or other kinds of standard grease. Enclosed slide valves have a

screw on top that needs to be unscrewed and removed to permit lubrication.

Check and replace with motor operated slide valves the lubricant sensor. – Data sheet lubricant sensor

see appendix .

Check the electrical connection for signs of oxidation, damage or leaks.

Check that the limit switches are working properly and are in good technical condition.

Make sure that the safety guard (cover plate) is attached securely.

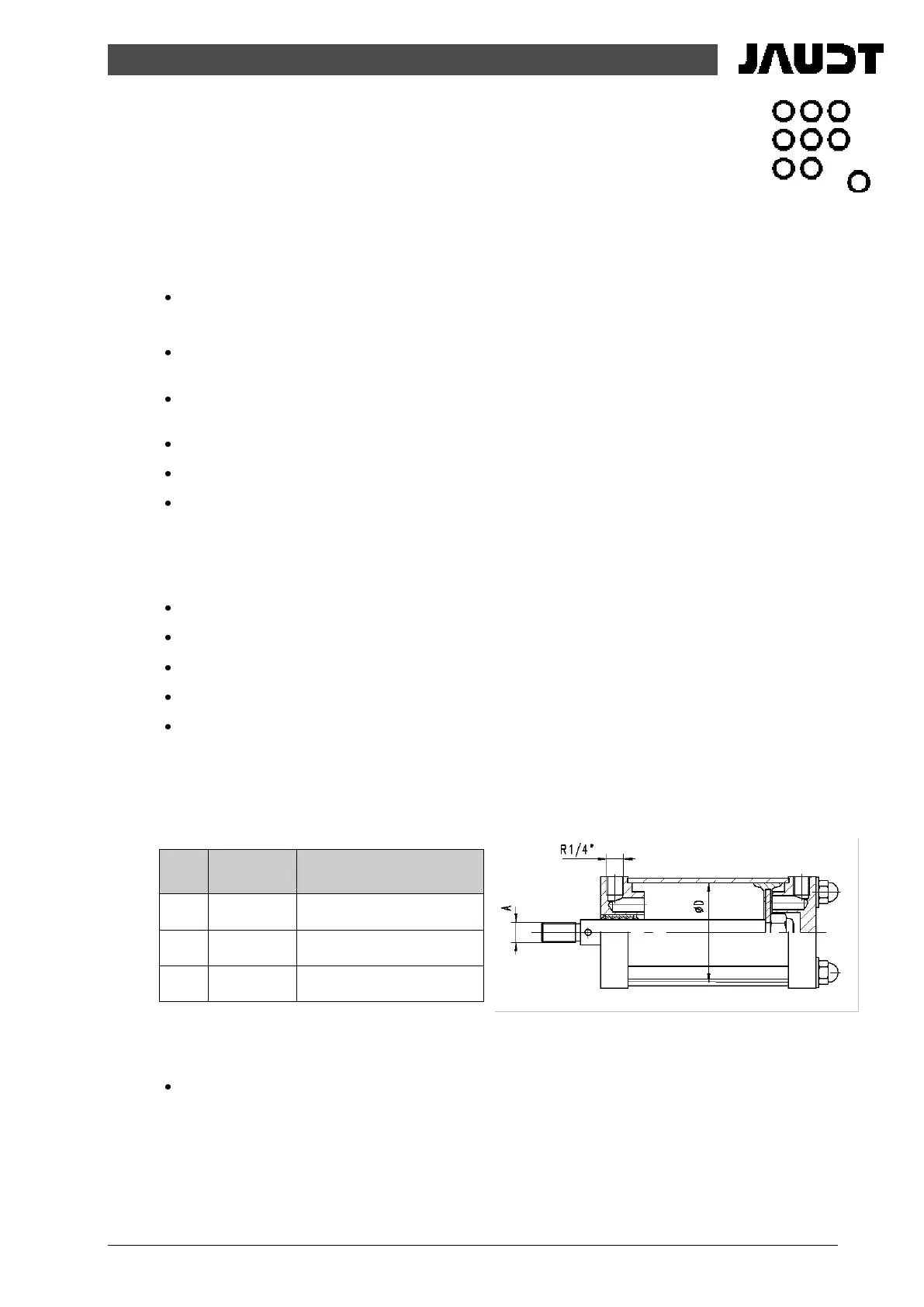

6.3 Electropneumatic drive

Electrical work must be carried out by trained electricians.

Check the pneumatic supply system and drain it if necessary.

Make sure that the magnetic valves are working properly.

Check whether there are any leaks in the pneumatic system.

Check that the limit switches (optional) are working properly and are in good technical condition.

Make sure that the safety guard is attached securely.

The cylinder liner of the electropneumatic drive features different diameters ØD depending on the nominal

width of the slide valve.

Tabular overview of repair kit for JAUDT electropneumatic drive:

6.4 Hydraulic drive

Inspection and maintenance must be carried out in accordance with the manufacturer's specifications

for the hydraulic cylinder (see insert).

Repair kit article number

Loading...

Loading...