G2

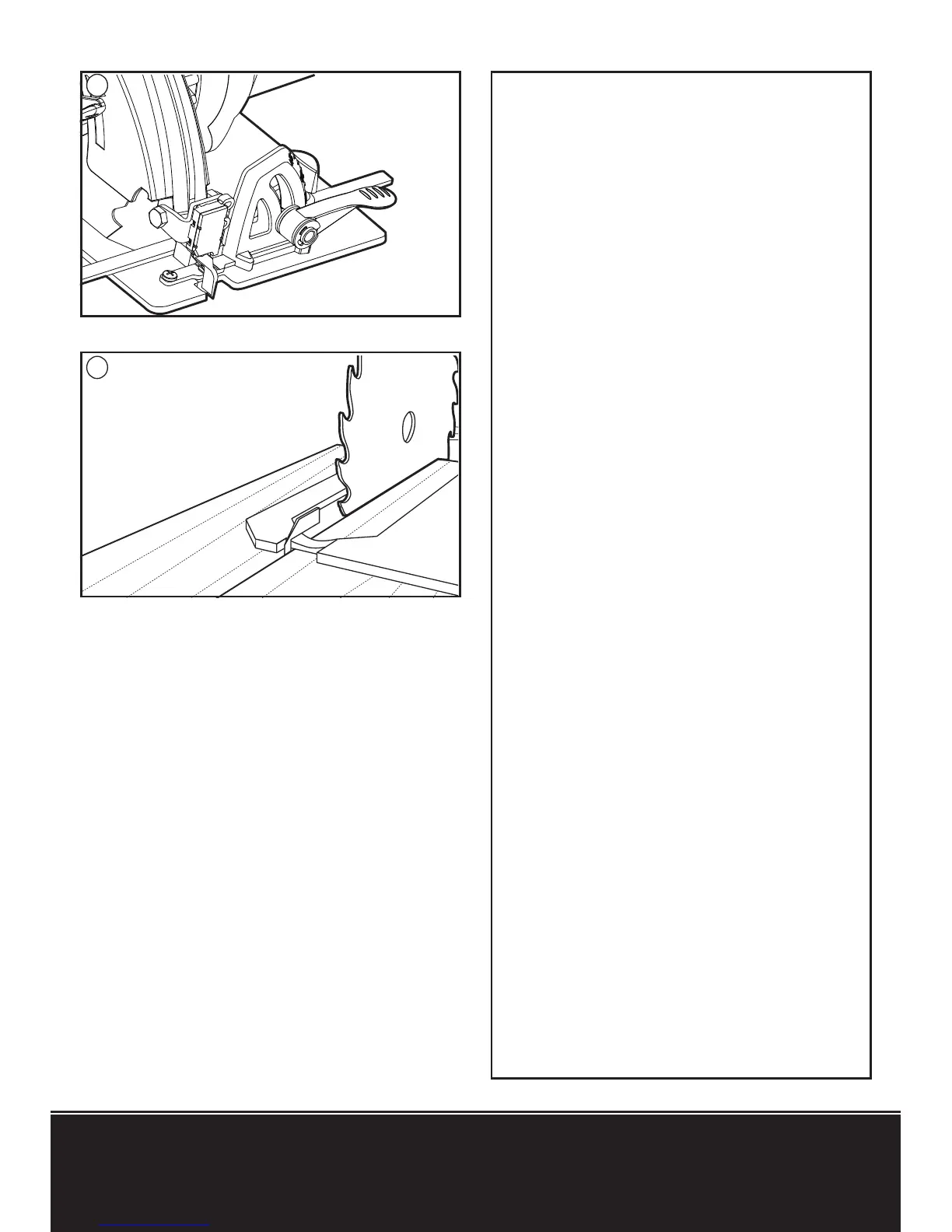

A. ADJUSTING THE CUTTING

ANGLE (See E&F)

Turn the base plate bevel lock (6)

in counter-clockwise direction to

loosen the angle scale. Tilt the

base plate away from the machine

until the required cutting angle is

adjusted on the bevel scale (4).

Tighten the bevel lock button(6) by

turning it in clockwise direction.

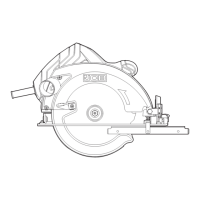

B. CUTTING GUIDE (See G1, G2)

The sight line (G2) fixed in front of

the base plate is used as cutting

guide. Always guide it along the

cutting mark made on the workpiece

for accurate cutting.

The cutting mark 0° indicates the

position of the saw blade for right-

angled cuts.

NOTE:

It is best to perform a

practice cut prior to starting work.

8. PARALLEL GUIDE

ADJUSTMENT

Used for making cuts parallel to

a work piece edge at a chosen

distance. Slide the parallel guide

arm through both fixtures to achieve

the required cutting distance and

tighten screw to lock into position

(See H2). It can be used from both

sides of the base plate (15). There is

a cutting guide notch on the front of

the base plate (15) for using with a

parallel guide (10). For straight cuts,

use the 0° guide mark to align with

G1

Loading...

Loading...