10 - 3

Operation

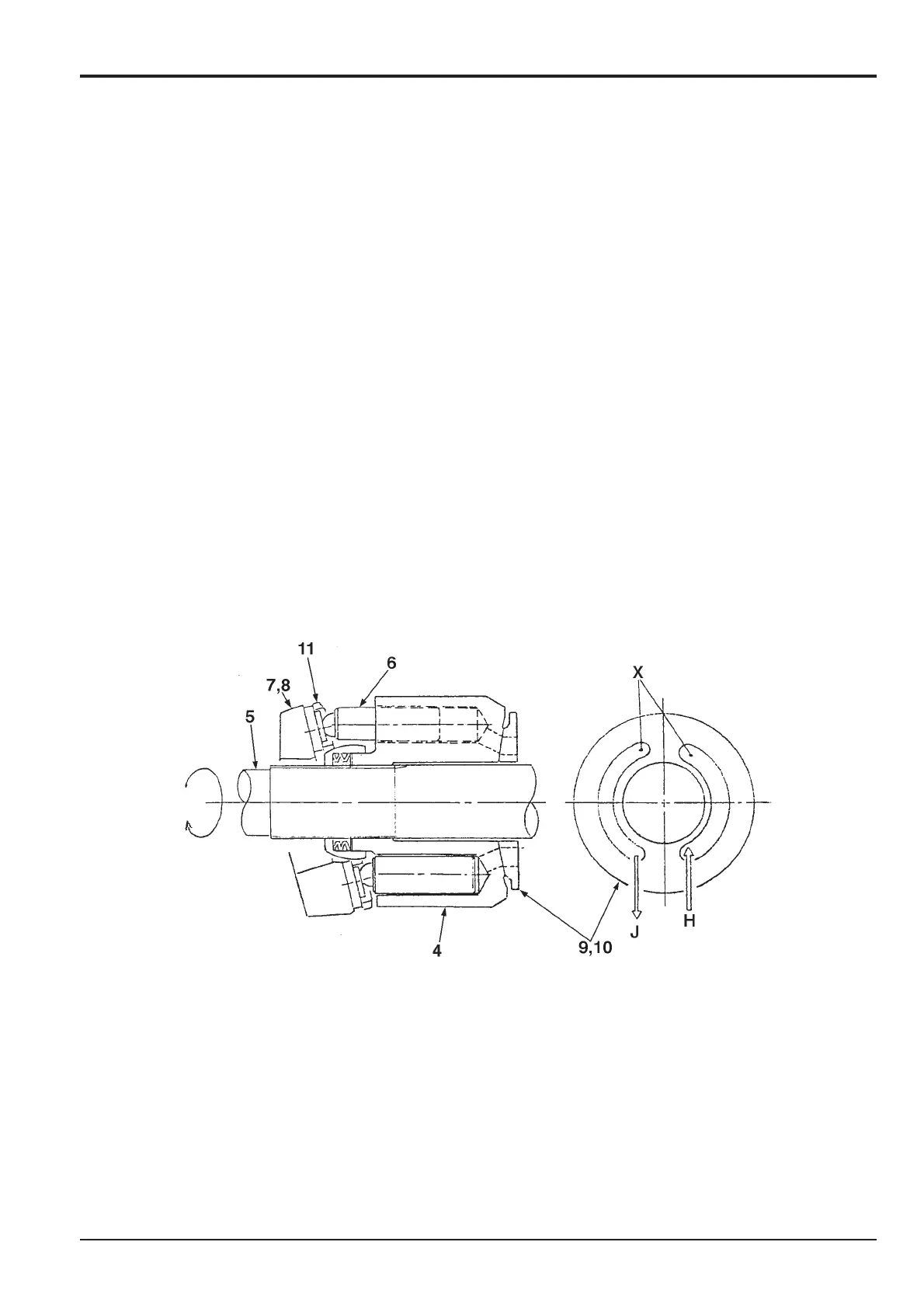

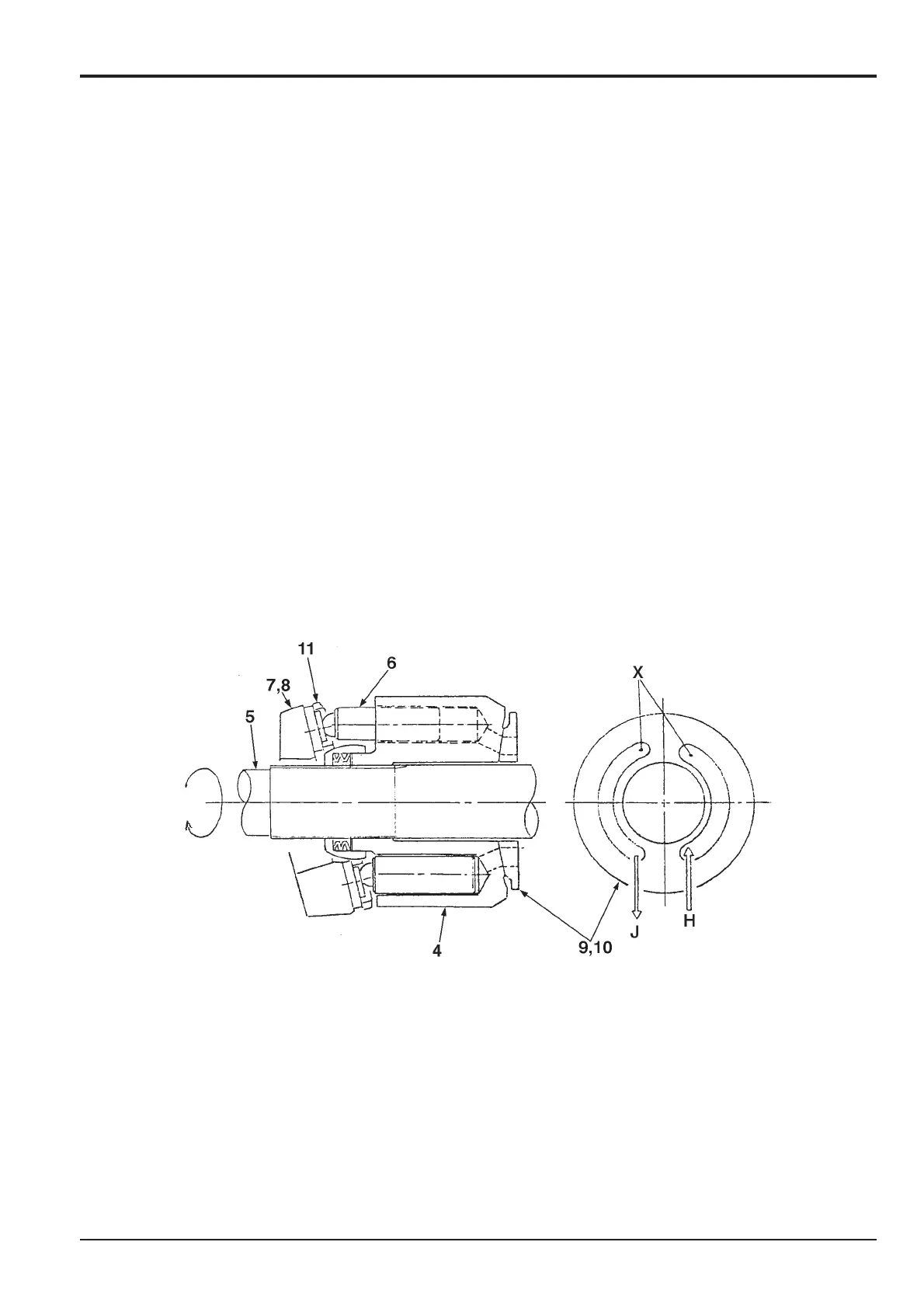

In the following descriptions the bold figures (e.g. 4) relate to

the items on the sectional and exploded views on pages

14 - 1 to 14 - 3 and the component list on page 14 - 4.

Main Pumps (P1 and P2)

Each pump consists of a cylinder block 4, containing nine

piston/shoe assemblies 6. Driven by shaft 5, the block

rotates between a variable angle, non-rotating swash plate

(7 on P1, 8 on P2) and a fixed valve plate (9 on P1, 10 on

P2).

Retainer plate 11 holds the piston shoes against the swash

plate. Due to the angle of the swash plate, as the cylinder

block rotates the pistons are forced to move back and forth

in their cylinders. The piston stroke, and therefore the pump

displacement, varies according to the swash plate angle,

which is controlled by machine demand.

The fixed valve plate 9 contains two crescent shaped ports

X. The valve plate is located so that when a piston reaches

its nearest point to the plate it comes into line with the pump

inlet port H. During the next 180° of cylinder block rotation

the piston draws oil into the cylinder bore. When the piston

reaches its furthest point from the plate it ceases to be in

line with the inlet port and comes into line with pump outlet

port J. The next 180° of cylinder block rotation causes the

piston to force oil from the cylinder bore through the outlet

port.

The process is carried out sequentially by the nine pistons to

provide a continuous smooth pump output.

Section E Hydraulics

9803/6410

Section E

10 - 3

Issue 1

Hydraulic Pump/Regulator

JS00060

Loading...

Loading...