18 - 7

Hydraulic Pump

Dismantling and Assembly

The working environment must be clean and the workbench

covered with a cloth or rubber sheet to prevent damage to

the components.

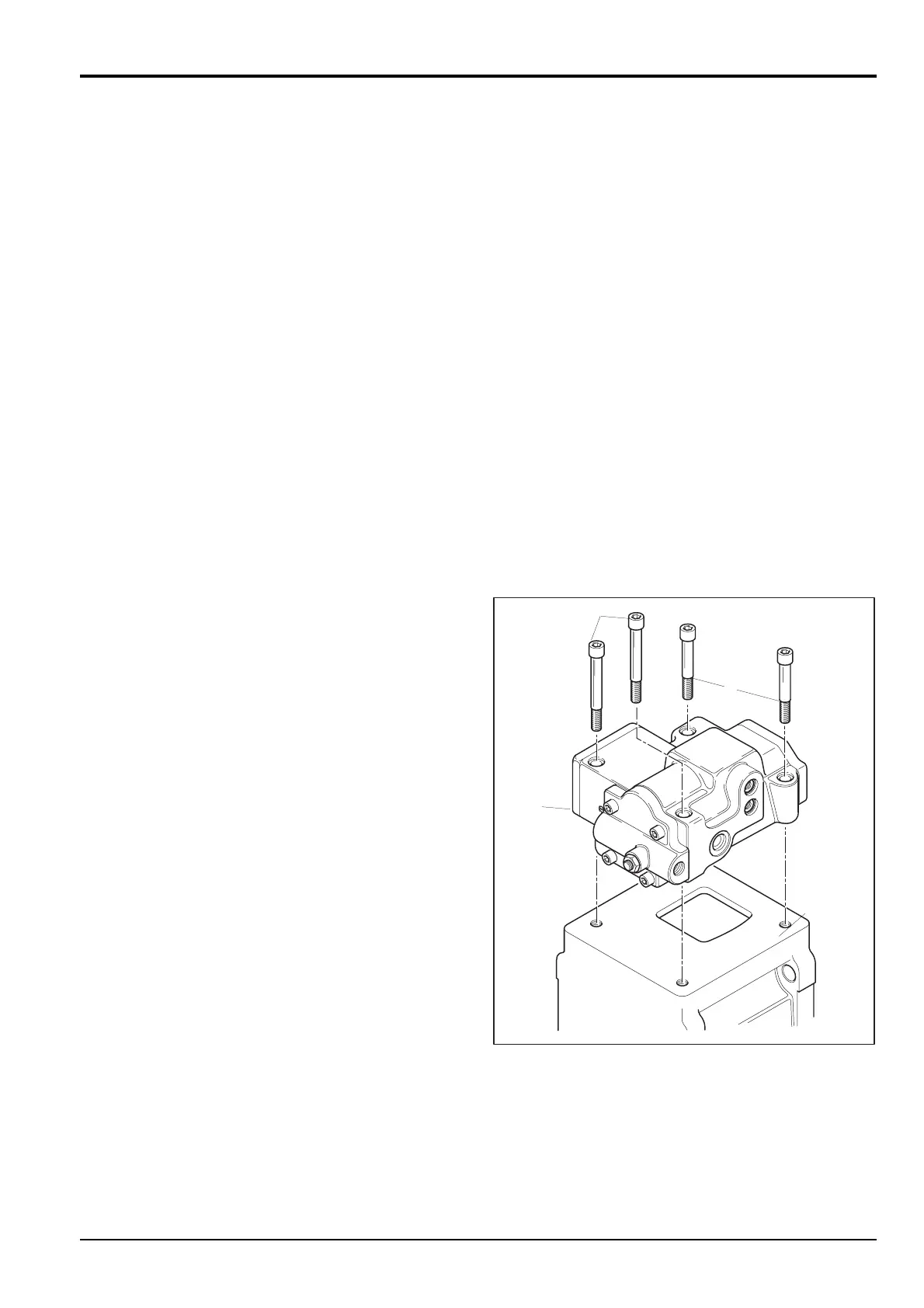

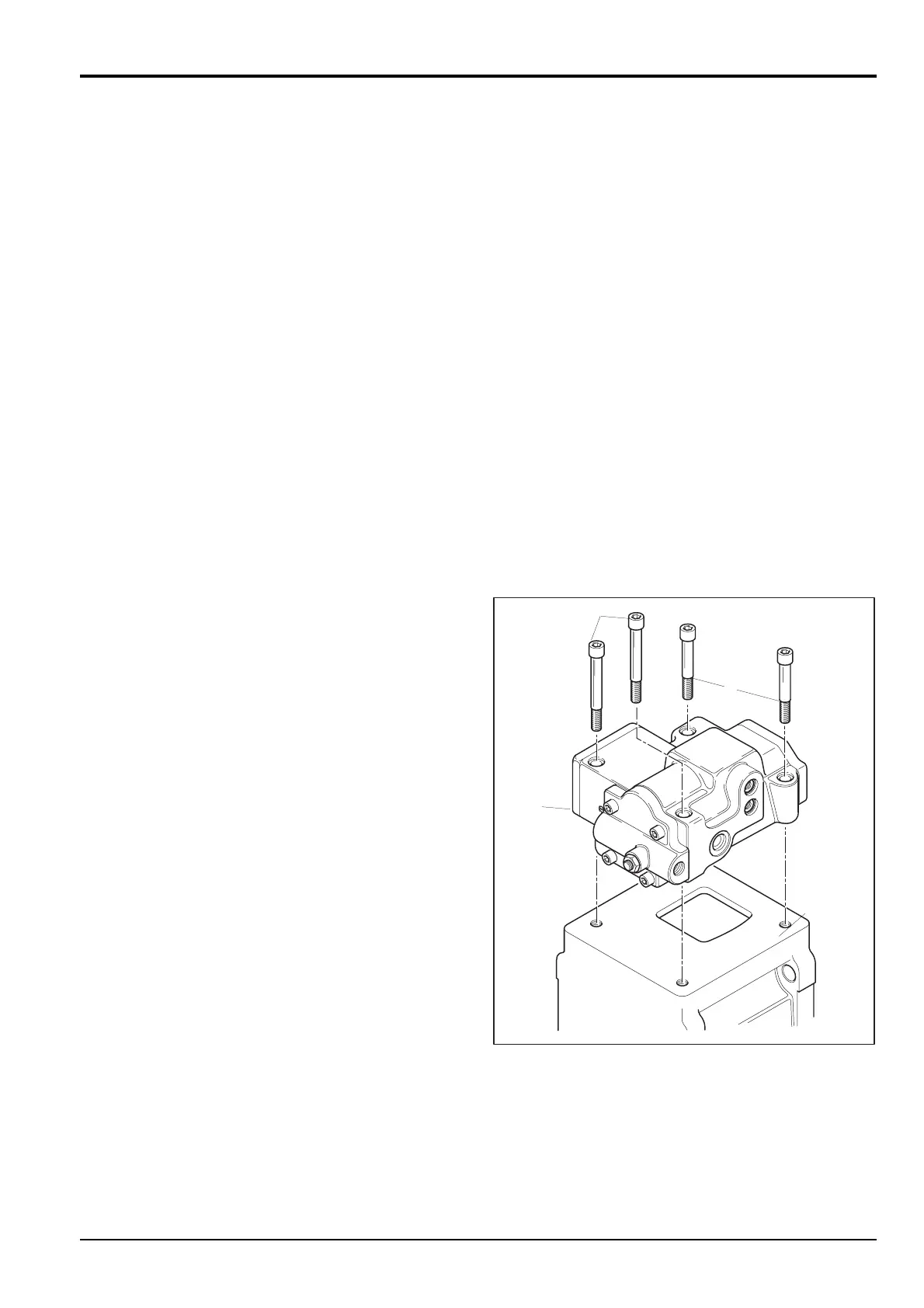

The illustration opposite shows both halves of the tandem

double axial piston pump, but the procedures refer mostly to

Pump 1. These procedures should also be applied to Pump

2 except where indicated otherwise.

Note 1: The components from one pump section must not

be mixed up with the corresponding components from the

other section and should be returned to the section from

which they came.

The item numbers called up in the following procedures

correspond with those in the exploded view.

Dismantling

Before dismantling, the pump ports should be plugged and

the external surfaces thoroughly cleaned to prevent the

ingress of dirt into the pump mechanism.

1 Remove drain plug 1 and let the oil drain into a suitable

receptacle.

2 As an aid to re-assembly, match mark the mating

flanges of regulator 4 and pump casing 5. Remove

socket head screws 2 and 3 (2 off each) and lift off the

regulator. Put the regulator to one side in readiness for

dismantling if required (see Regulator, Dismantling).

3 Remove the gear pump assembly 6.

Section E Hydraulics

9803/6410

Section E

18 - 7

Issue 1

Hydraulic Pump/Regulator JS130, JS160

Loading...

Loading...