Dismantling (cont’d)

25 To remove circlip 145, place the cylinder block on a

press capable of exerting a pressure of at least 100 kgf

(220 lbf) and compress spring 114 by means of a

suitable tubular tool (see Service Tools, Section 1)

pressing on washer 110.

During this operation, protect the machined surface of

the cylinder block with suitable sheeting.

26 Remove circlip 145, followed by washer 110, spring 114

and the second washer 110.

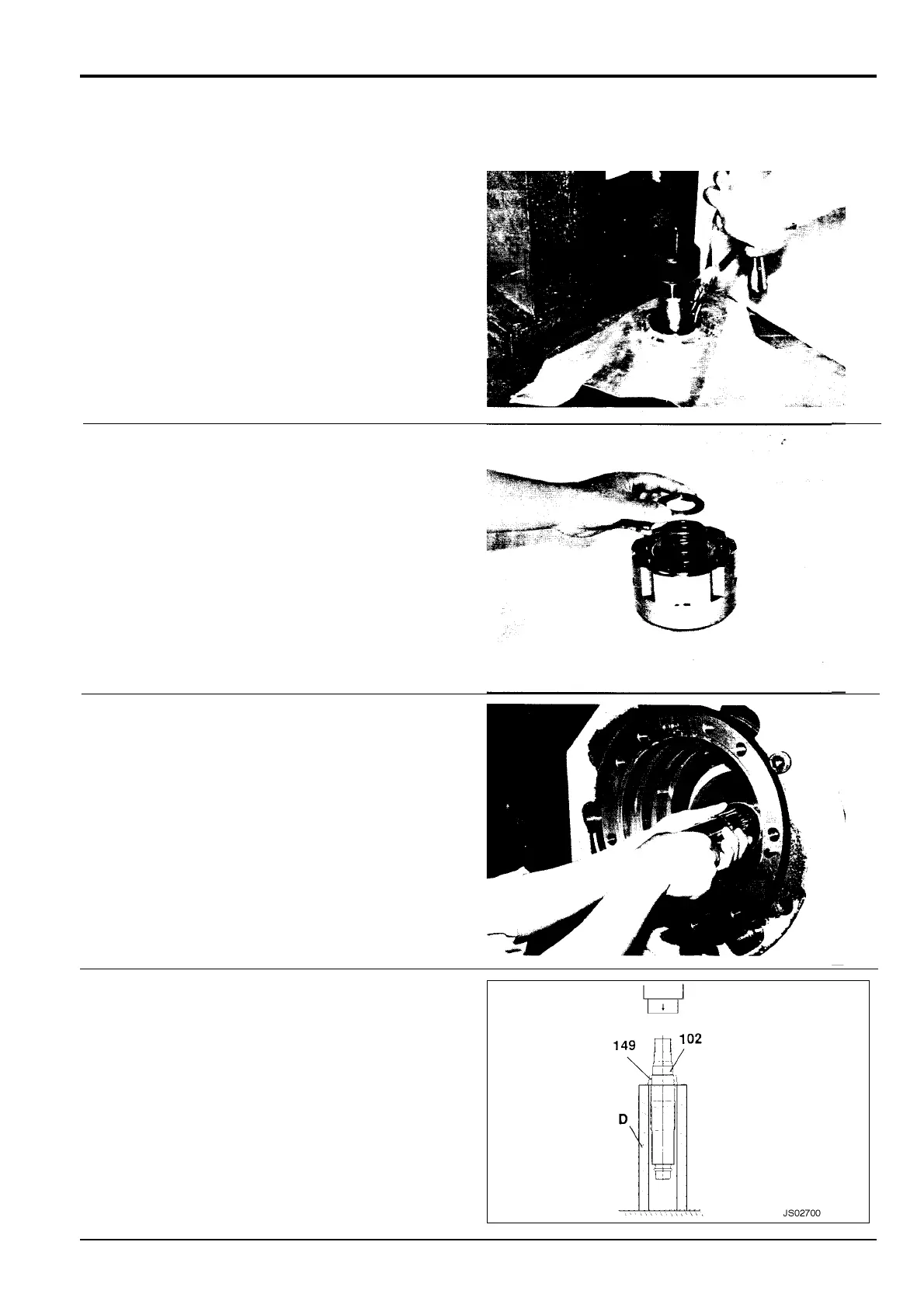

27 Remove shaft 102 complete with inner race of bearing

149.

28 If bearing 149 is to be renewed, press the shaft 102 out

of the bearing inner race. Support the bearing by means

of a suitable tube D (see Service Tools, Section 1).

8 - 9

Section F Transmission

9803/6410

Section F

8 - 9

Issue 1

Traction Motor

Loading...

Loading...