4 - 4

Slew Motor Pressure Relief

1. Prepare the machine

Put the operators lever into neutral, lower the gate lock

lever. Start the engine and place the machine on level

ground, lower and open the dipper and set the bucket on

the ground. Stop the engine.

2. Release the hydraulic oil tank pressure.

(See Releasing Tank Pressure).

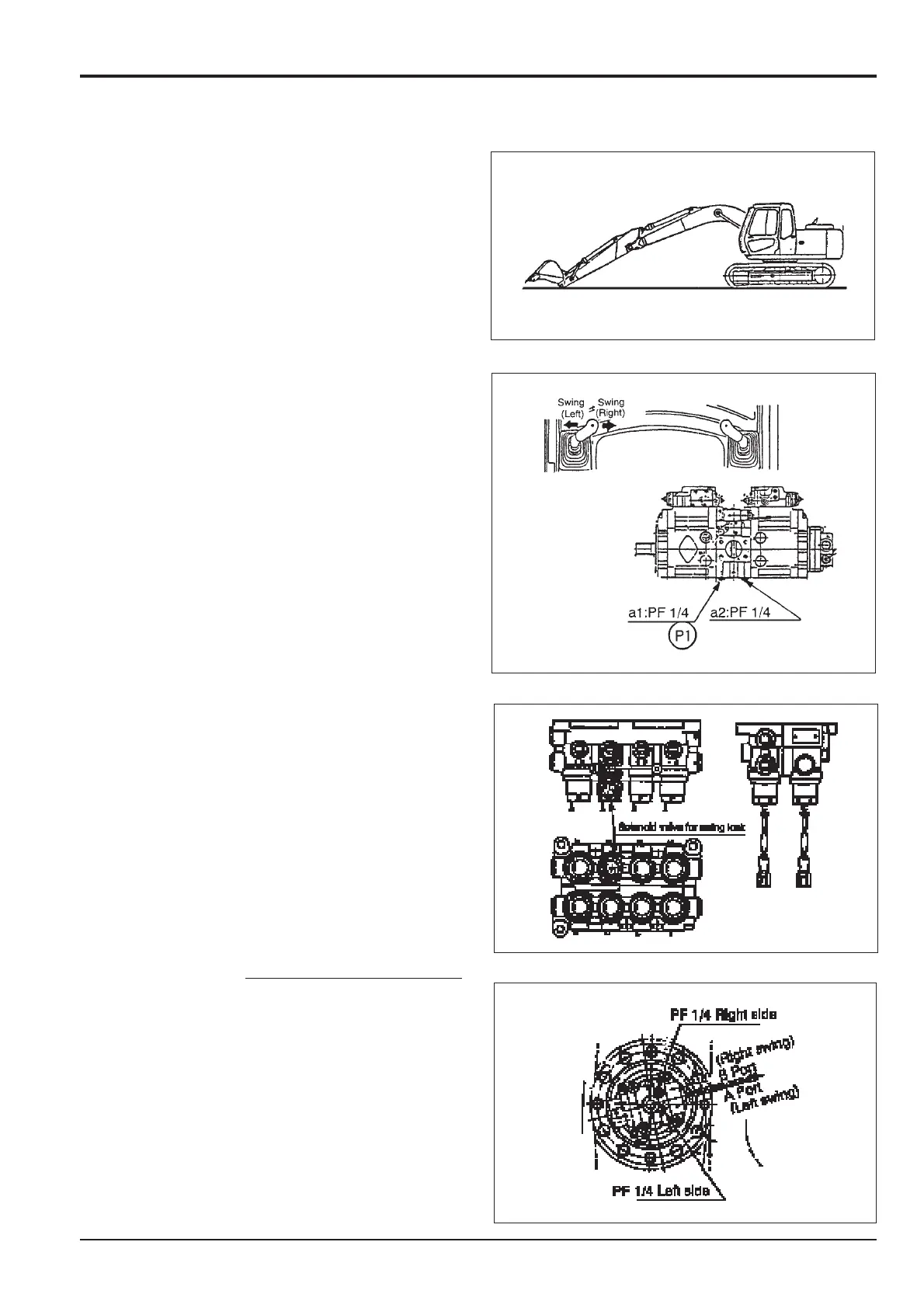

3. Connect a 0-500 bar (0-7000 lb/in

2

) pressure gauge and

adaptor to the port marked P1 on the pump.

4. Initiate slew lock procedures.

a. Remove the water-proof connector on the slew lock

solenoid valve, which is on the hydraulic pump side.

b. Press the slew lock switch which is on the left hand

console inside the cab, and confirm that the slew

(swing) lock symbol appears on the monitor.

c. Start the engine, and operate the engine at around

1000 r.p.m, then operate the slew lever slowly. Listen

to confirm that the relief sound is heard and that the

machine does not slew.

d. Run the engine at maximum no-load speed and in the

S mode.

e. Operate the slew lever.

5. Confirm the pressure of 299.8 ± 14.4 bar (4408 ± 213

lb/in

2

) at the gauge.

Notes:

1. If the water-proof slew lock solenoid valve is not

removed, slew lock status can be obtained with the

slew lock switch ON, but slew relief is not carried out.

2. Wire colour code to the solenoid is Dark Green.

3. Pressure measurement is also possible on the slew

motor, upper section.

6. If the pressure is within the limits, stop engine release

tank pressure and remove the gauge and adaptor; If the

readings are outside the limits, continue as below.

7. Pressure Adjustment

a. Confirm the present pressure reading.

b. The difference between the set pressure and the

present pressure determines the number of shims F

required for adjustment.

The No of shims = Set pressure-Present Pressure

4.83 bar (71.1 lb/in

2

)

8. Remove the relief valve assembly from the slew motor.

Note: If both relief valves are removed at the same time,

mark them left and right to facilitate reassembly in the

correct position.

Section E

Hydraulics

9803/6400

Section E

4 - 4

Issue 2*

Pressure Testing

*

Loading...

Loading...