23 - 5

Regulator Assembly

Clean each part in a suitable solvent and dry using

compressed air.

Inspect all parts and replace as required.

Care must be taken not to let dust or dirt adhere to parts after

cleaning and that parts do not become dented, scratched or

damaged.

Fit new 'O' rings, plugs, packing and oil seals, and apply

clean hydraulic fluid to all sliding parts before installation.

1. Assemble the compensatory rod (623) into the

compensatory hole of the casing (601).

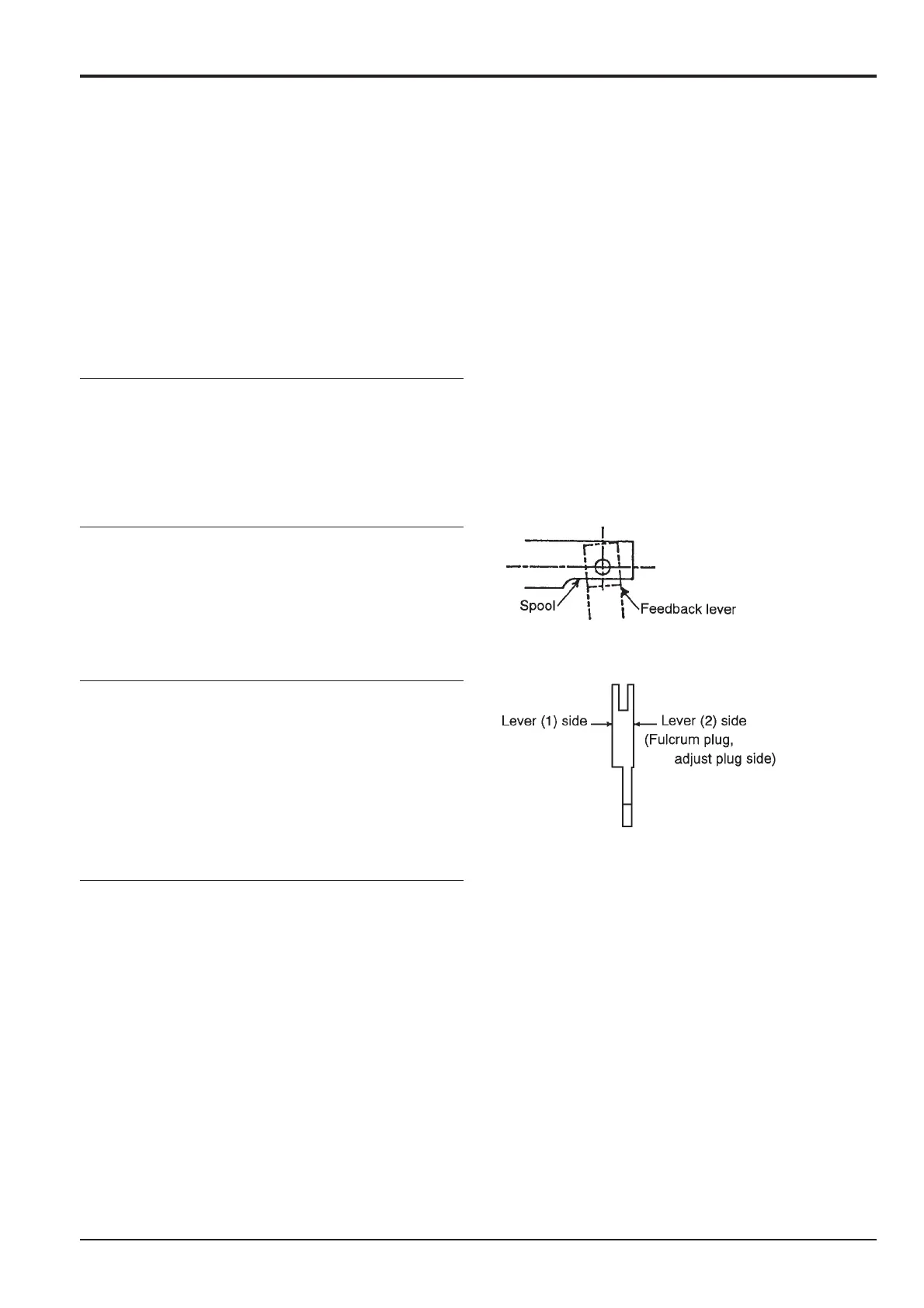

2. Insert the pin which is press-fitted into the lever (1) (612)

into the compensatory rod groove and assemble the pin

which is press-fitted into the casing to the lever (1).

3. Assemble the spool (652) and sleeve (651) into the

spool hole of the casing.

Note: (1) Confirm that the spool and sleeve slide smoothly

inside the casing. (2) Be careful of the spool direction.

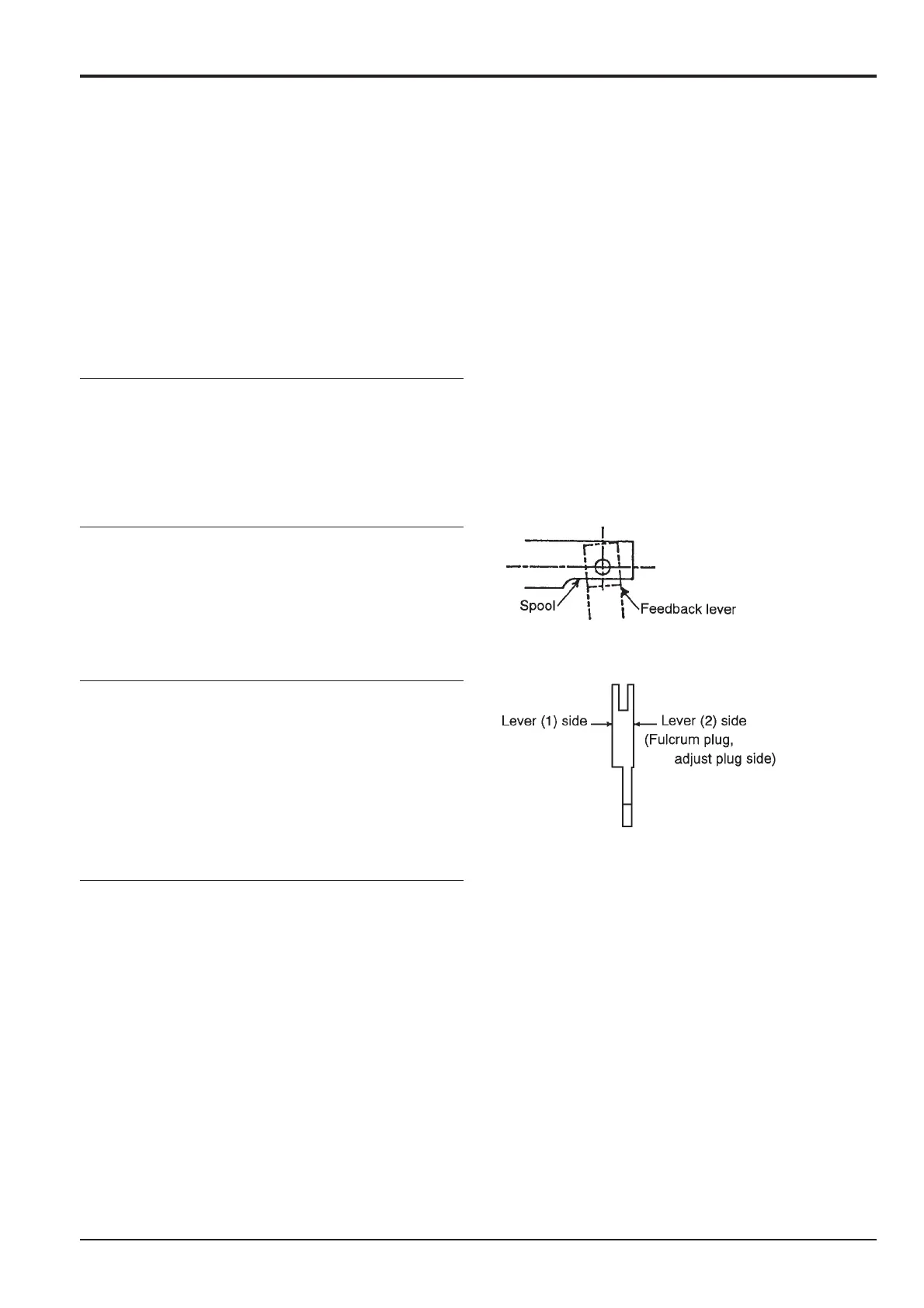

4. Assemble the feedback lever (611) and insert the pin

(874), aligning with the feedback pin hole.

Note: (1) To facilitate work, insert the pin a little into the

feedback lever beforehand. (2) Be careful not to mistake the

direction of the feedback lever.

5. Assemble the pilot piston (643) to the casing hole for

flow rate control.

Note: (1) Confirm that the pilot piston slides smoothly.

All tapped holes and gasket faces should be thoroughly

degreased by washing as liquid packing and adhesive is

used on all gasket surfaces and threads.

Apply adhesive to the final few threads of a bolt or screw. Do

not apply excessive amounts of adhesive. Wipe off any

surplus liquid packing.

Ensure that the pump controllers are fitted to the positions

from which they were removed.

Section E

Hydraulics

9803/6400

Section E

23 - 5

Issue 2*

Regulator JS200. JS240

*

Loading...

Loading...