40

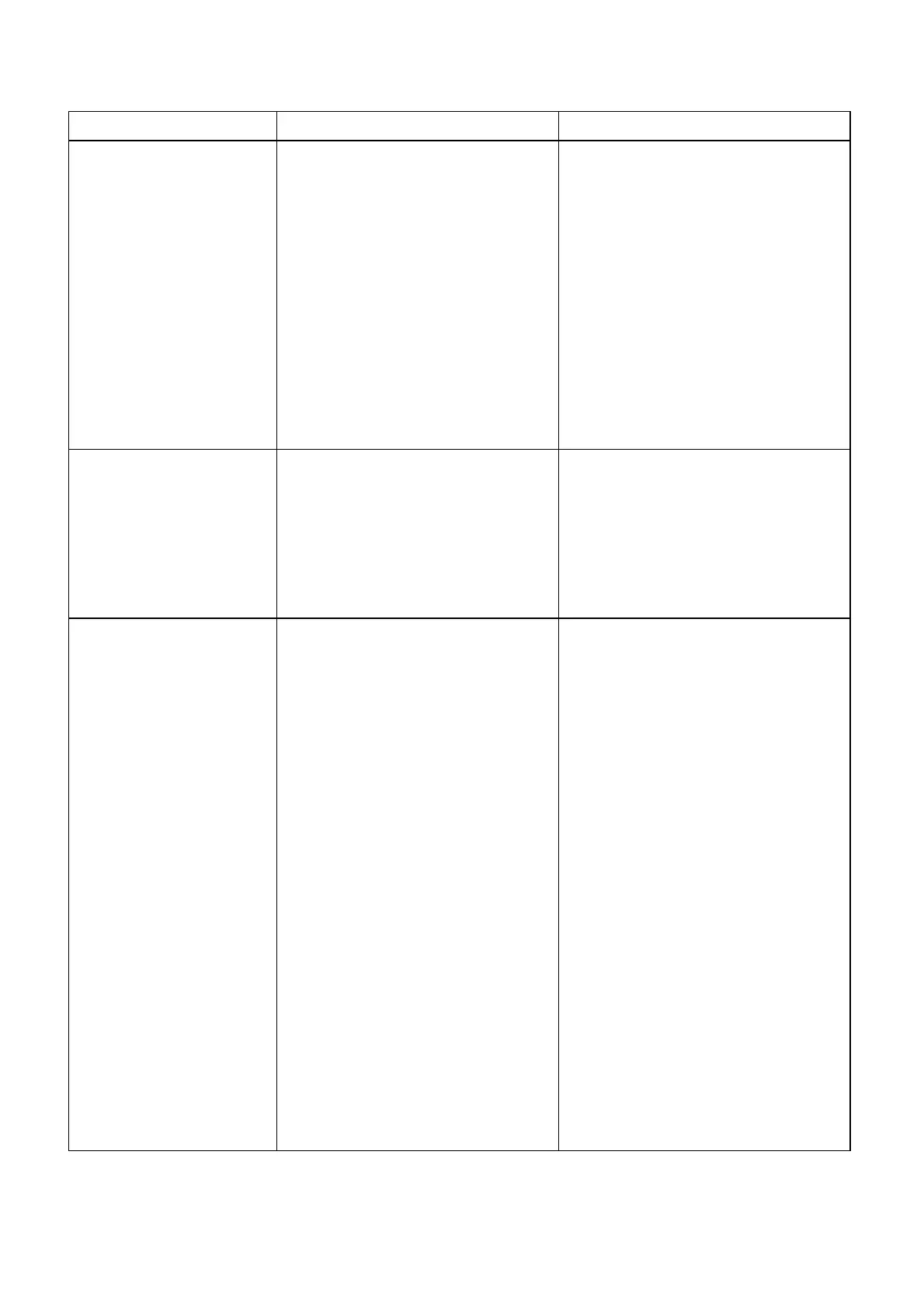

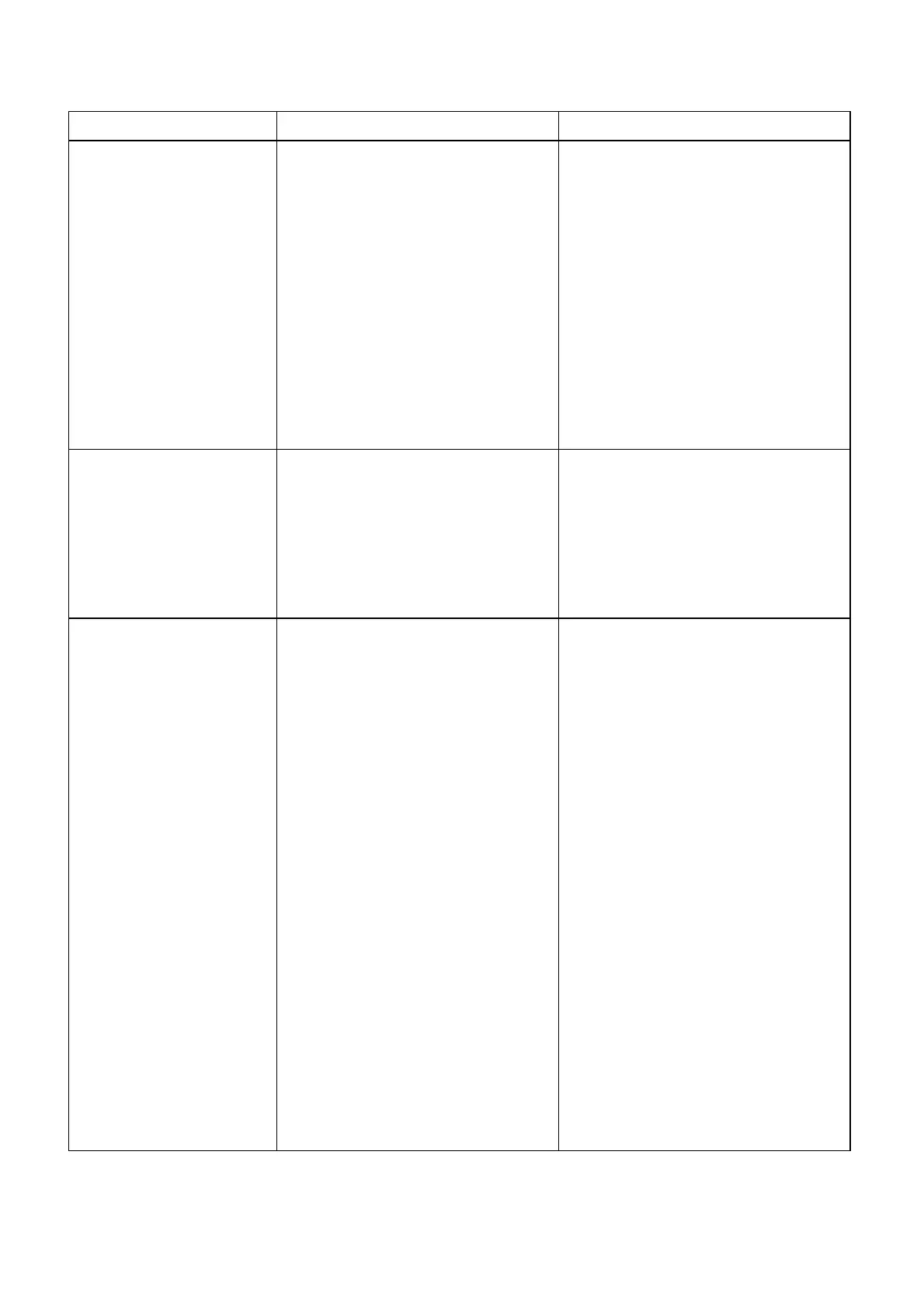

TROUBLE SHOOTING

TROUBLE

PROBABLE CAUSES

REMEDY

1 .Oil level In headstock Is too low or Replenish or discharge the oil to the

too much. proper level.

2.Quality and viscosity of oil is wrong. Replace the oil with recommended type.

3.Oil is too dirty. Replace the oil..

4.Oil hole in bearing is obstructed by Remove the dirt from the oil hole

dirt.

5. Bearing obstructed by dirty. Clean the bearing and renew oil.

6.Badly worn bearing. Replace bearing.

7. Bearing is not in proper position. Dismantle and reassemble it.

8. Bent or sprung main spindle. Straighten or replace it.

Overheat of headstock bearings

9.Too much end thrust. Adjust thrust nut.

1.Plug of drain not tight. Resealing and tighten.

2.Case cracking. Repaired by special welding.

Oil leakage 3.Leakage from overflow. Tighten cover screws.

4.Packing or gasket damaged. Replace packing or gasket.

5.Leakage from overflow on spindle Less oil flow to bearing or enlarge oil

bearing housing. return flow.

1. Badly worn bearing. Replace bearing.

2. Lost levelling. Recheck levelling & tighten.

3. Badly worn V belts. Replace V belts.

4. Loose belt tension. Adjust belt tension.

5. Badly worn gear. Replace gear.

6. Bent or sprung shaft. Straighten or replace shaft.

7. Pulley lossened Tighten pulley set screw.

8. Clamp of workpiece in loose status. Tighten clamp.

9. Bearing thrust too loose. Tighten end thrust nut.

Excess noise or vibration 10. Headstock not tighten on bed. Tighten fixed screws.

of machine 11. Excess clearance between the Adjust the gib and tighten back

carriage and bed. clamp.

12. Excess clearance in cross or Adjust taper gib.

compound slide.

13. Cutting tool failure. Replace correct cutting tool or regrind it

14. Tool holder not tight enough. Tighten again check for debris..

15. Weak tool shank or too long. Replace with rigid tool or reset.

16. Unbalance of workpiece while high Balance workpiece or reduce spindle

speed running. speed.

Loading...

Loading...