22

CLEANING OR LEVELLING LATHE

WARNING: DISCONNECT ALL ELECTRIC POWER BEFORE CLEANING, LEVELLING OR

MAINTENANCE LATHE.

CLEANING

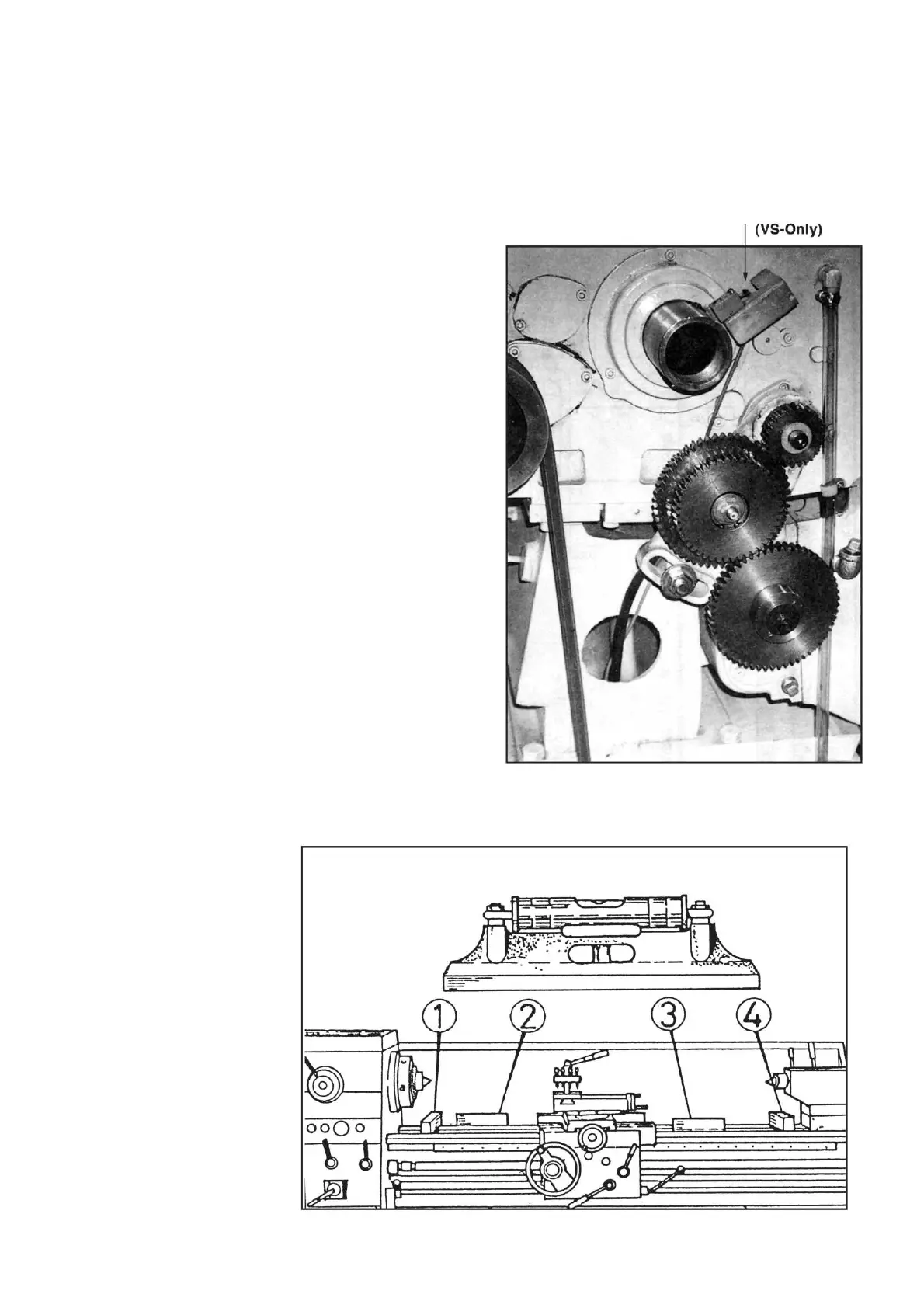

Before operating any controls, remove the anticorrosion coating

from all slideways and the end gear train; see Fig. 1, using white

spirit or Kerosene.

DO NOT USE CELLULOSE SOLVENTS FOR CLEANING AS

THEY WILL DAMAGE THE PAINT FINISH.

Oil all bright machined surfaces immediately after

cleaning, using machine oil or slideway lubricant; use

heavy oil or grease on the end gears.

INSTALLING

Locate the machine on a solid foundation, allowing sufficient

area all round for easy working and maintenance (see

Foundation Plan). The lathe may be used free-standing or

bolted to the foundation.

FREE-STANDING

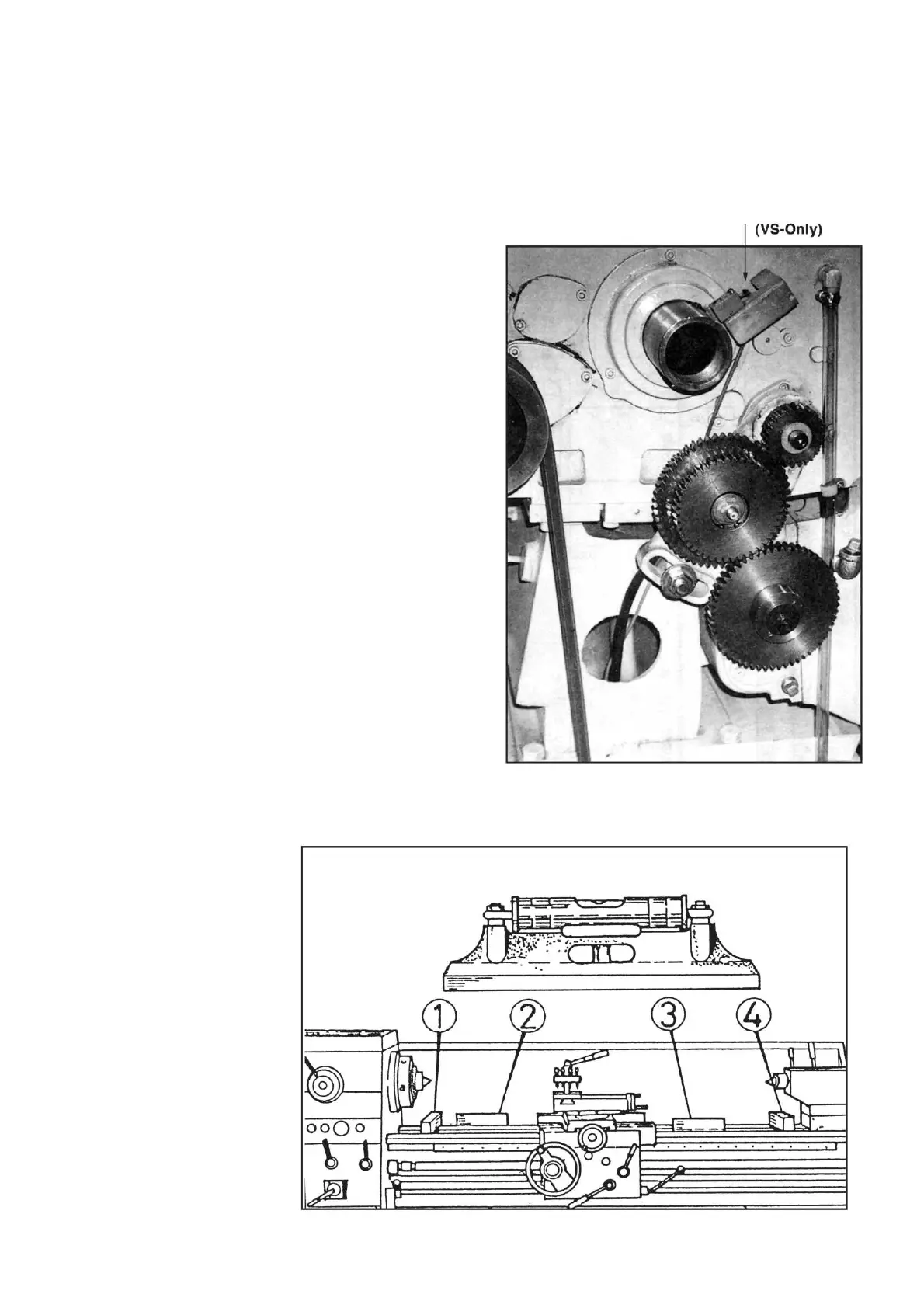

Position lathe on foundation and adjust each of the eight/ten

mounting feet to take equal share of the load. Then using a

machinist’s precision level on the bedways (as in Fig 2) adjust

the feet to level up machine. Periodically at least every six (6)

months check bed level to ensure continued lathe accuracy.

FIXED-INSTALLATION

Position lathe over four bolts (1/2 in. or 13mm. diam.) set into

the foundation to correspond with holes in the mounting feet;

dimensions are shown on foundation plan. Accurately level the

machine, as in Fig. 2 then tighten hold-down bolts. Re-check

bed level.

Fig.1

Fig. 2

Loading...

Loading...