12

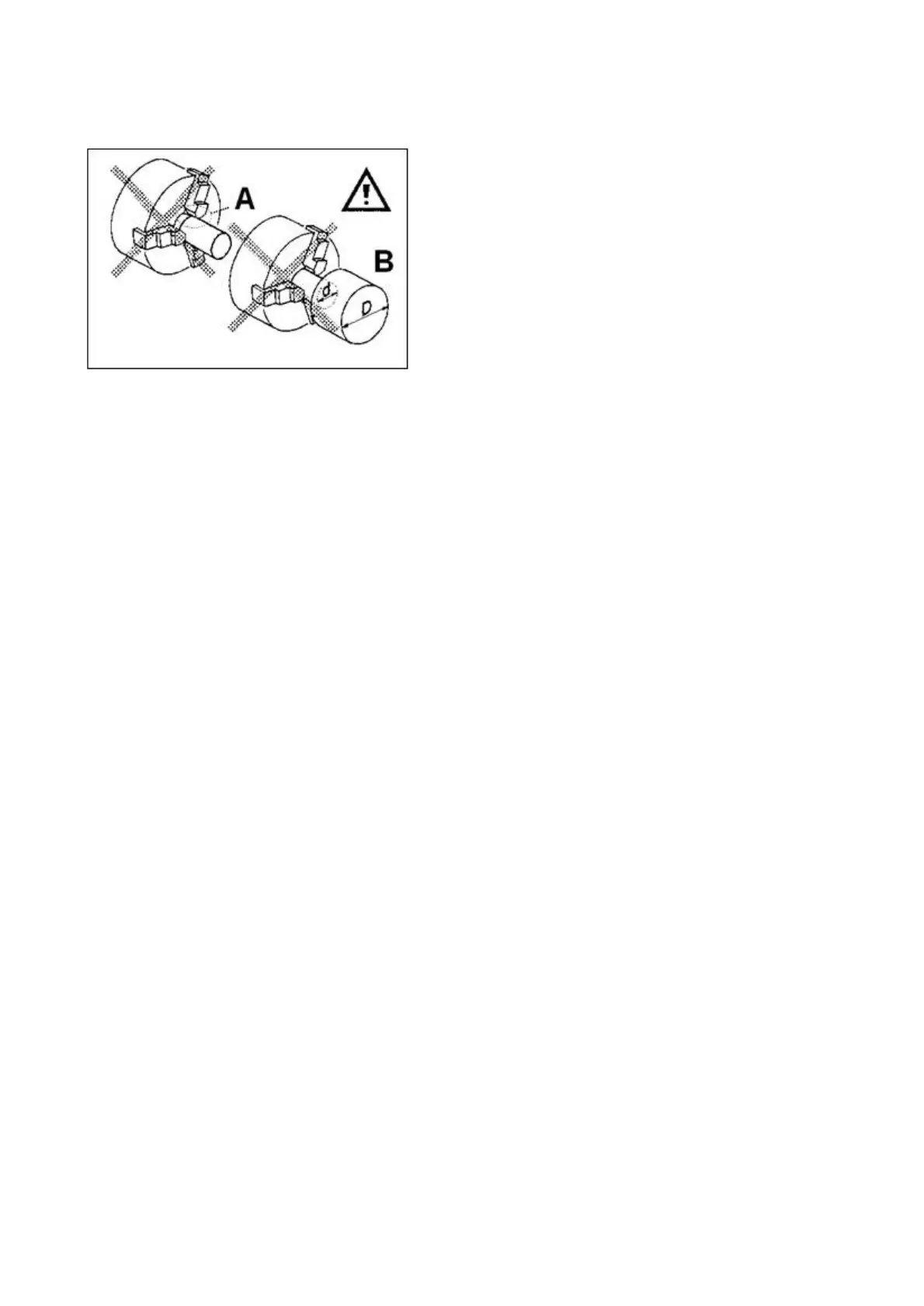

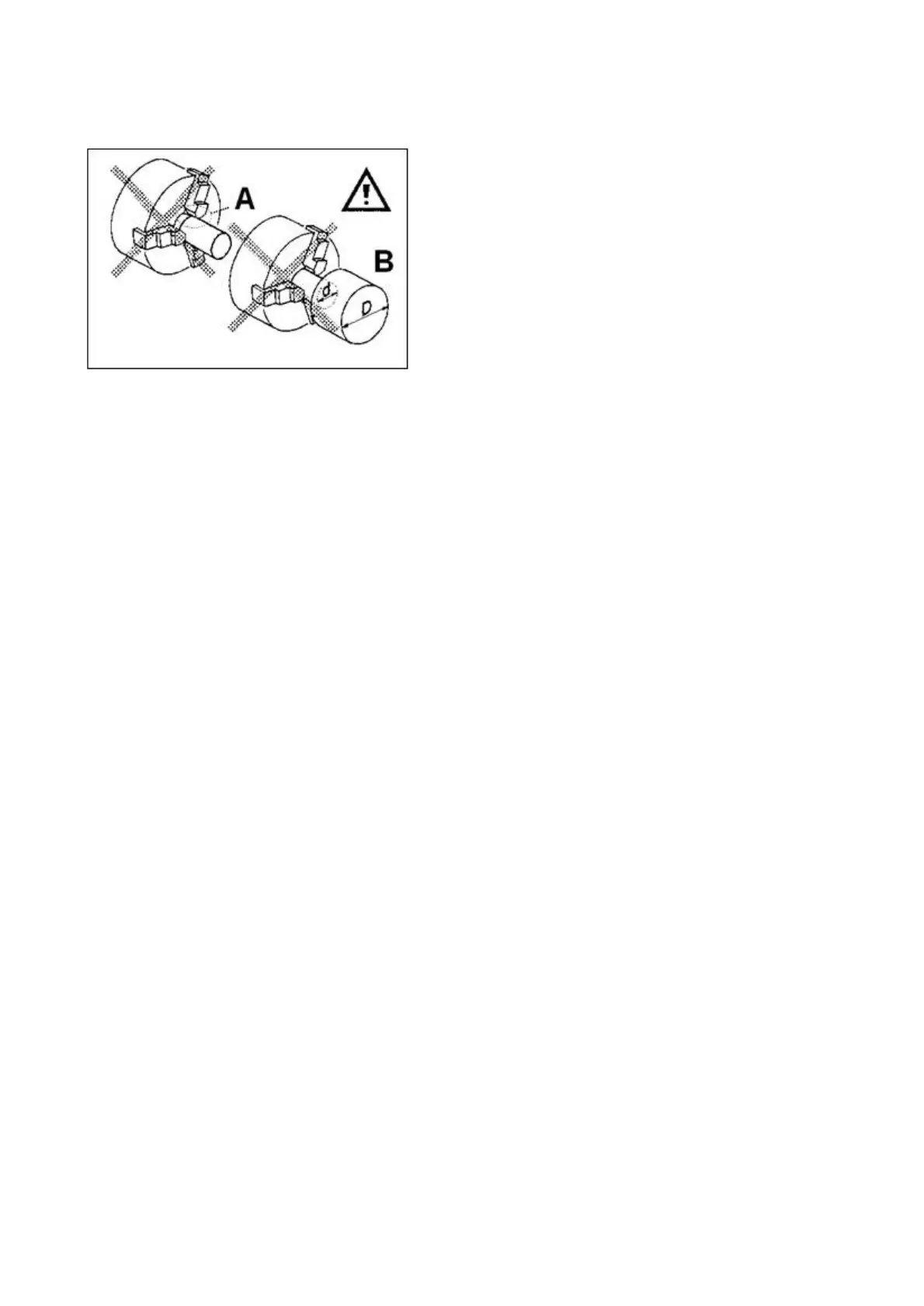

Fig 10

Face locate the workpiece for added support.

6.2 Tool setup

The cutting angle is correct when the cutting edge is in

line with the centre axis of the work piece. Use the point

of the tailstock centre as a gauge and shims under the

tool to obtain the correct centre height.

Use a minimum of two clamping screws when installing

the cutting tool to the four way tool post.

Avoid big tool extensions.

6.3 Spindle speeds selection

The correct spindle speed depends on the type of

machining, the cutting diameter, the material to be

machined and the cutting tool.

These are recommended max. speeds for a 50mm

cutting diameter with carbide (HM) tools:

Aluminium, brass 1500 RPM

Cast iron 1000 RPM

Mild steel 800 RPM

High carbon steel 600 RPM

Stainless steel 300 RPM

If high speed steel (HSS) tools are used about 5 times

lower speeds must be chosen.

Generally speaking, the larger in relation the cutting

diameter, the smaller the possible RPM.

For example:

Turning mild steel at a diameter of 25mm allows a

speed of

1600 RPM max. with carbide tool

320 RPM max. with HSS tool

To change the spindle speed:

The speed may never be changed when the spindle

or motor are still running.

Move the speed select levers (2, Fig 1) according to

the speed you desire.

It may be necessary to turn the chuck by hand to help

the gears to engage.

6.4 Turning with auto feed

Several automatic longitudinal and cross feeds are

readily available by selection on the gearbox levers

(20, 22, 23, Fig 1).

Do not shift levers while the machine is running.

Move the feeding lever (14, Fig 2):

- left /right for longitudinal feed.

- up/down for cross feed

The correct feed depends on the material to be

cut, the cutting operation, the type of tool, the

rigidity of the work piece chucking, the depth of

cut and the desired surface quality.

For example:

Longitudinal OD-turning, mild steel of 25mm diameter

with a carbide tool at 1200 RPM and with rigid

chucking.

Stock removal and roughing cut:

Depth of cut 2mm

Feed per revolution 0,25mm

Finishing cut:

Depth of cut 0,5mm

Feed per revolution 0.1mm

Loading...

Loading...