Controls

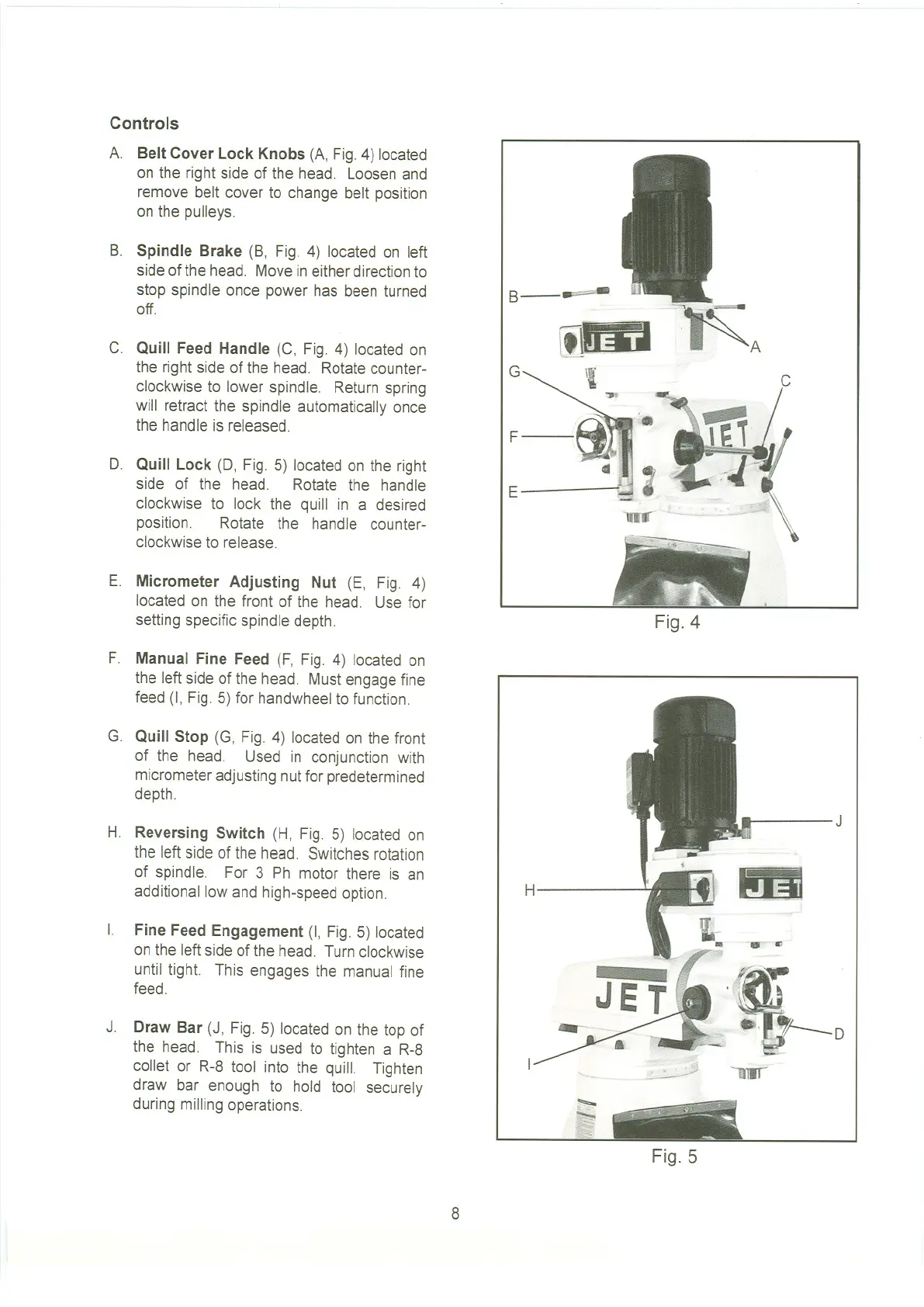

A. Belt Cover Lock Knobs (A, Fig. 4) located

on the right side of the head. Loosen and

remove belt cover to change belt position

on the pulleys.

B. Spindle Brake (B, Fig. 4) located on left

side of the head. Move ineither directionto

stop spindle once power has been turned

off.

C. Quill Feed Handle (C, Fig. 4) located on

the right side of the head. Rotate counter-

clockwise to lower spindle. Return spring

will retract the spindle automatically once

the handle is released.

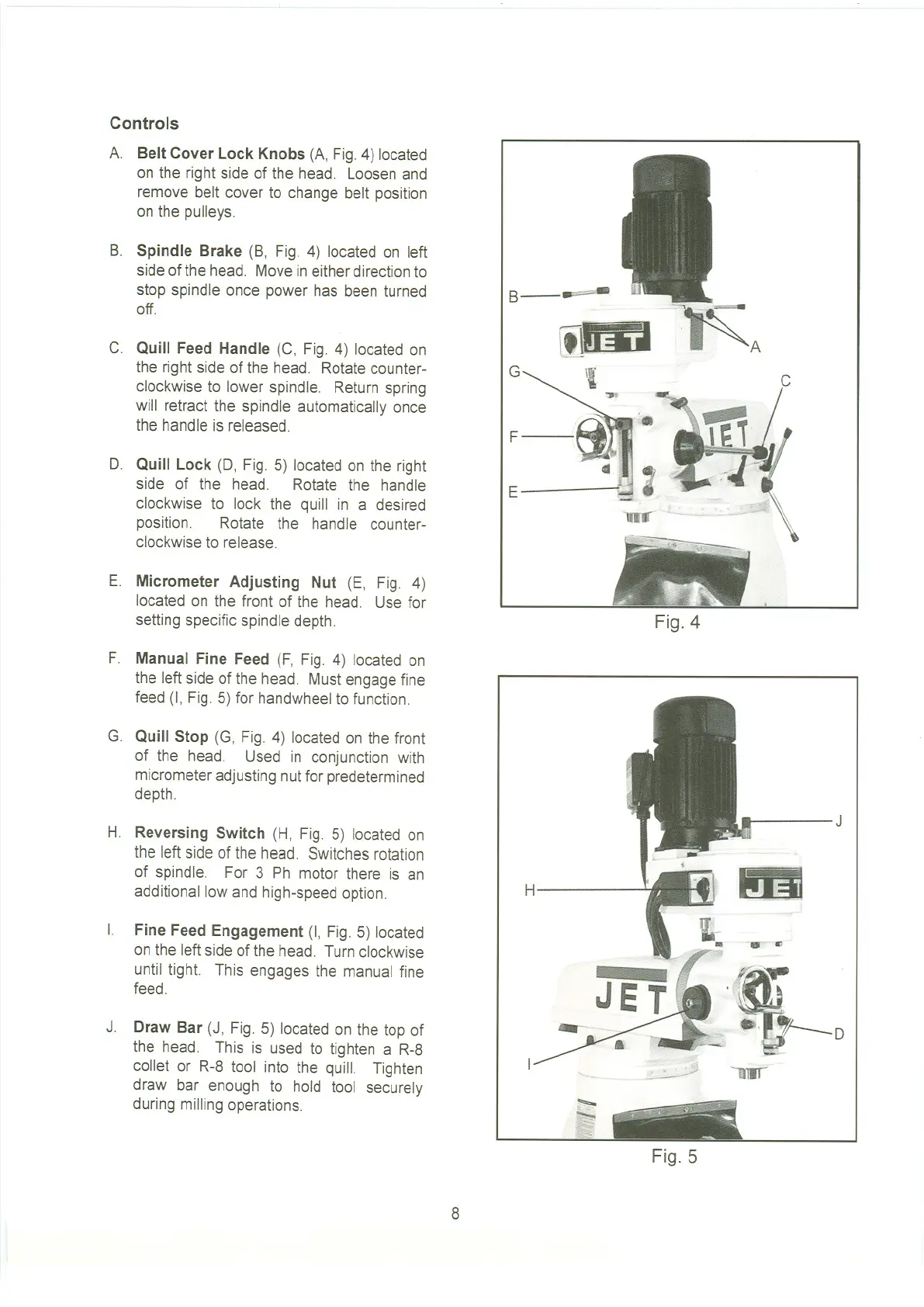

D. Quill Lock (0, Fig. 5) located on the right

side of the head. Rotate the handle

clockwise to lock the quill in a desired

position. Rotate the handle counter-

clockwise to release.

E. Micrometer Adjusting Nut (E, Fig. 4)

located on the front of the head. Use for

setting specific spindle depth.

F. Manual Fine Feed (F, Fig. 4) located on

the left side of the head. Must engage fine

feed (I, Fig. 5) for handwheelto function.

G. Quill Stop (G, Fig. 4) located on the front

of the head. Used in conjunction with

micrometer adjusting nut for predetermined

depth.

H. Reversing Switch (H, Fig. 5) located on

the left side of the head. Switches rotation

of spindle. For 3 Ph motor there is an

additional low and high-speed option.

I.

Fine Feed Engagement (I, Fig. 5) located

on the left side of the head. Turn clockwise

until tight. This engages the manual fine

feed.

J. Draw Bar (J, Fig. 5) located on the top of

the head. This is used to tighten a R-8

collet or R-8 tool into the quill. Tighten

draw bar enough to hold tool securely

during milling operations.

G

B-II"""-"-

F

E

Fig. 4

J

H

".. CI

Fig. 5

8

Loading...

Loading...