Insulation Equipment + Supply 8 InsulationEquipmentSupply.com

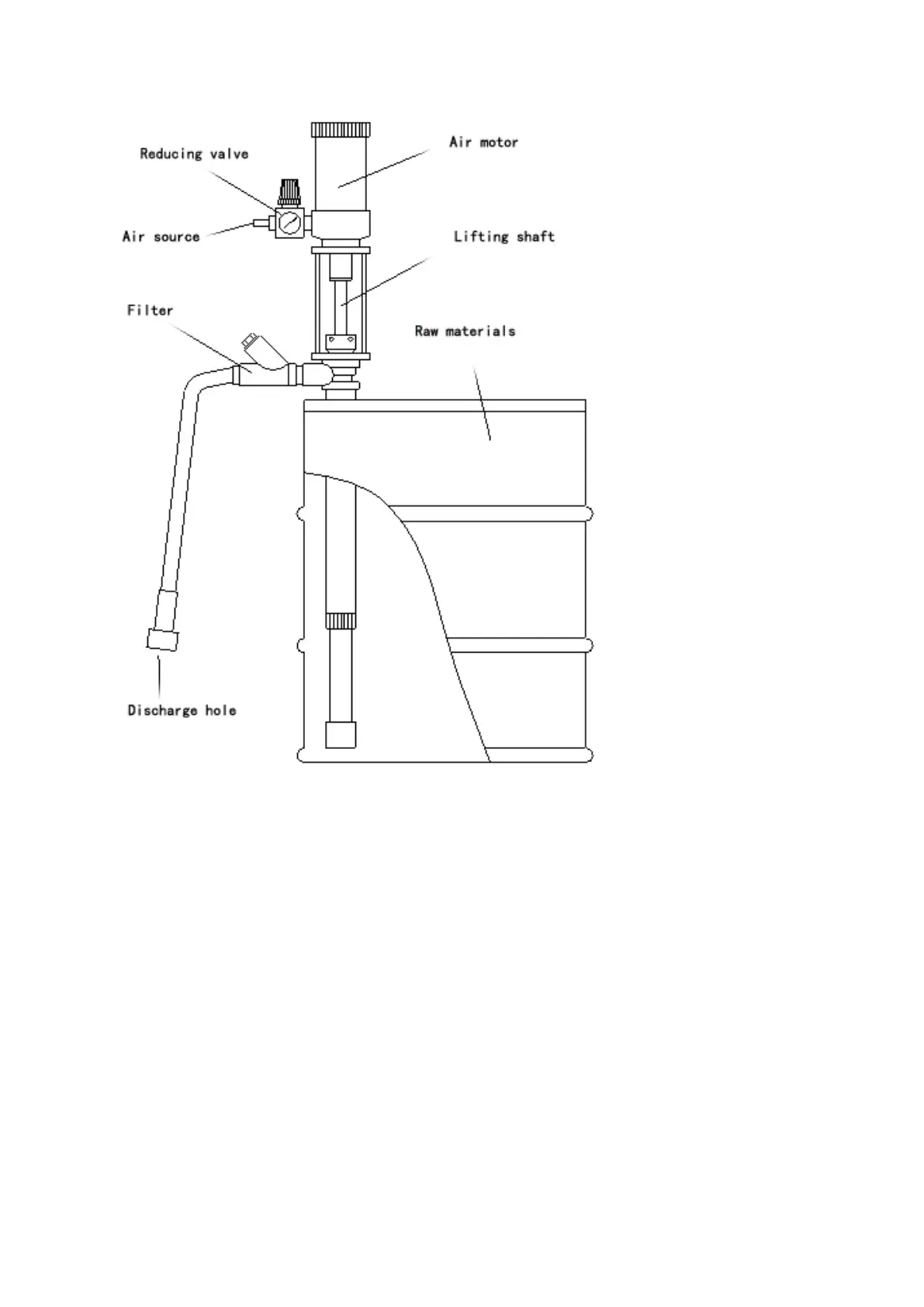

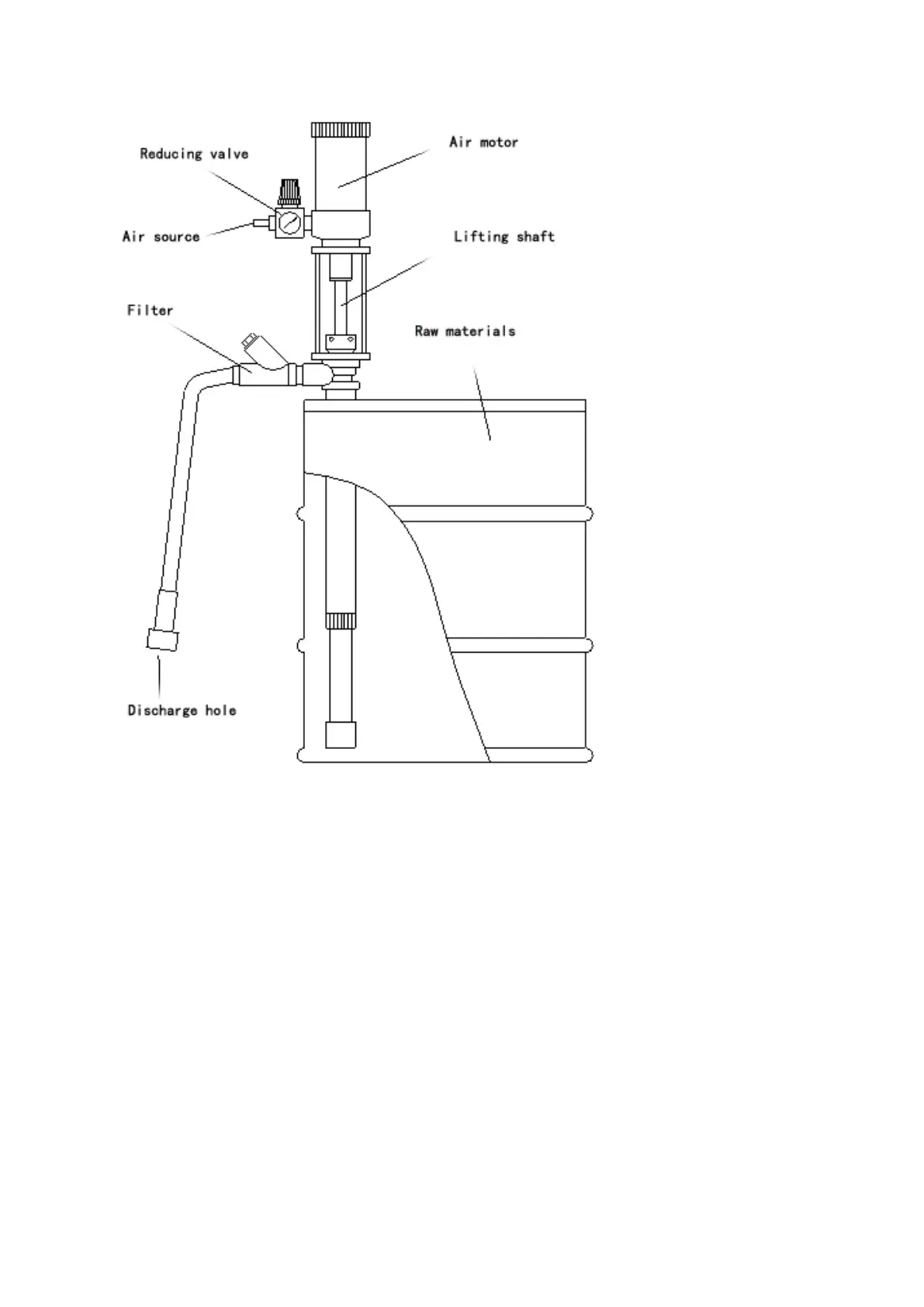

Figure 2

Step 2 , connect the feed pump conveying hose to the discharge hole filtered by the feed pump and the

inlet of pump body of the host respectively. See Figure 3.

(2) Installation of the discharging system:

Firstly, remove the plastic insulation sleeve that outside of the temperature sensor wholly, feed the

temperature sensor (armored extra-long thermocouple) at the exit of the main machine exit slowly into the

black material pipe through the black material joint of the heat preservation hose group (the hose end is

protruding). Attention shall be needed to avoid hard bending of the sensor sleeve and care shall be paid to

protect the sensor on the tip. Then, the feed material is delivered out of the heat preservation hose set in

sequence and is sent to the sprinkler gun via the main machine. This step is very easy. The hose run shall be

clearly identified to avoid incorrect connection. When the connection from the main machine to the

polyurethane sprinkler gun feed hose set is completed, it should look like Figure. 3.

(3) If it is necessary to lengthen the hose because of the construction condition, then the hose shall be

connected according to Figure(4) and the output voltage of the transformer for hose heating needs to be

adjusted to increase the heating power and satisfy the power requirement. The output voltage shall be

compatible with the pipe run length. For adjustment, observe “connect point for pipe extension” label on

the equipment and choose the voltage and connection location from Table 1 below.

Note: The factory standard configuration of this equipment is the 15m heat tracing pipe and insulation pipe,

the output voltage of the transformer for the insulation pipe is 12V.

Loading...

Loading...