11

Joerns Liing and Repositioning

Model HML400, C-HLA, C-HLA-2, C-HLA-2T

© 2015 Joerns Healthcare • IM-459001 RevC • 15-2003

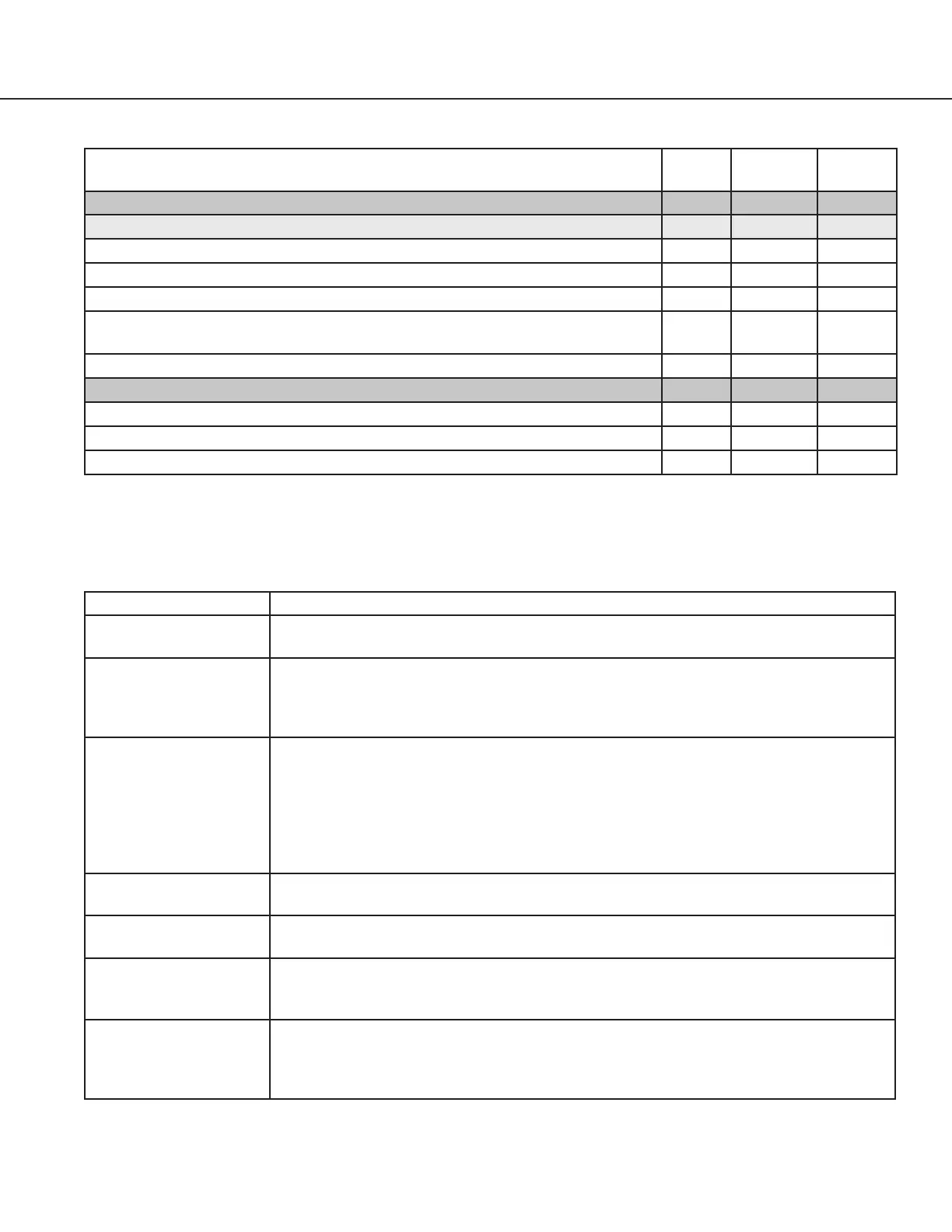

Troubleshooting, Power Unit

Symptom Action

Handle mounting holes

loosening or enlarging

• Periodically oil the pivot point

Jack lowers with patient

suspended

• Check to make sure the pressure release knob is completely closed.

• Check valve not sealing. Pump handle rapidly several times, then open pressure

release knob and pull down on boom. Repeat two or three times.

• Replace the jack

Jack fails to lift to

full height

• Air in oil under ram– pump unit up as far as it will go. Open pressure release knob and

pull down on boom to lowest position. Repeat until lift raises to full height.

• Unit may be low on oil– remove jack from lift, collapse ram. Remove socket screw

(located on top of top cap) and put 1oz. of #10 weight hydraulic oil in at a time until the

jack ram moves the proper distance.

NOTE– Proper amounts of oil for a jack when completely empty are 7 3/4 oz. for 12" stroke; 11 1/2 oz. for

17" stroke; 3 3/4 oz. for 6" stroke; 12 1/2 oz. for 19" stroke.

Oil leaking from

around piston

• Replace the jack

Oil leaking around rim of

top cap

• Replace the jack

Unit will not lower • Lay jack on its side. Remove and clean release cartridge making sure small holes are

cleaned out with pin or small diameter wire.

• Replace the jack.

Jack is noticeably loose

in the mounting bracket

located at the base of

the jack.

• Refer to “Inspection of Hydraulic Pump Stud” section to tighten the mounting stud for

the jack.

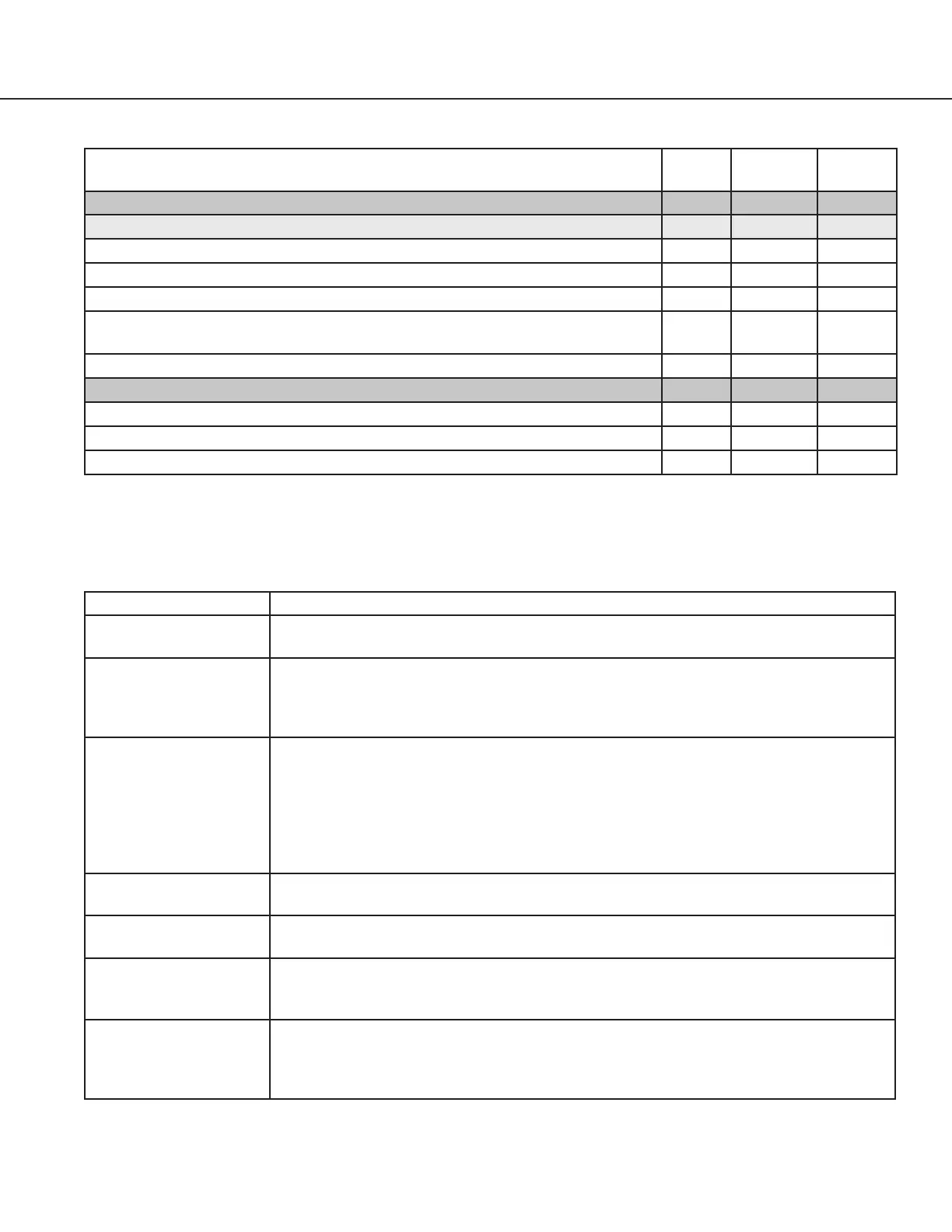

Lifter Maintenance Checklist continued...

Item Initially Before

each use

Bi-

Monthly

Lubrication

Oil all pivot joints, including:

Top of mast where boom attaches

✔

Top and bottom of actuator mounting

✔

Pump handle hinge

✔

Use a light grease to lubricate base adjustment lock plate and

all rotating hardware.

✔

Wheel and swivel bearings

✔

Cleaning*

Use mild soap to clean; dry thoroughly.

✔

Apply auto or appliance wax

✔

Keep painted surfaces clean from oil

✔

Loading...

Loading...