If several measuring runs are necessary to balance

a wheel because balance weight size and position

have to be adjusted repeatedly, this is often due to

insufcient measurement accuracy.

If this is the case the operator can electronically

calibrate the rotating masses on the machine; which

is called User Calibration.

A calibration run takes longer than a regular measuring

run.

Following User Calibration any residual compensation

will be cancelled.

Readjustment

Make sure that no clamping tool (and no wheel or

other device) is mounted on the machine shaft.

From the MAIN MENU (Fig. 6-1) press the F2 key

three times and select the F1 CALIBRATION key

(1, Fig. 6-2).

The CALIBRATION 1 screen (Figure 6-5) page will

open.

Close the wheel guard, press the START key and

launch the rst calibration run (if the run takes a

long time it means residual imbalances have been

detected).

The CALIBRATION screen 2 will open.

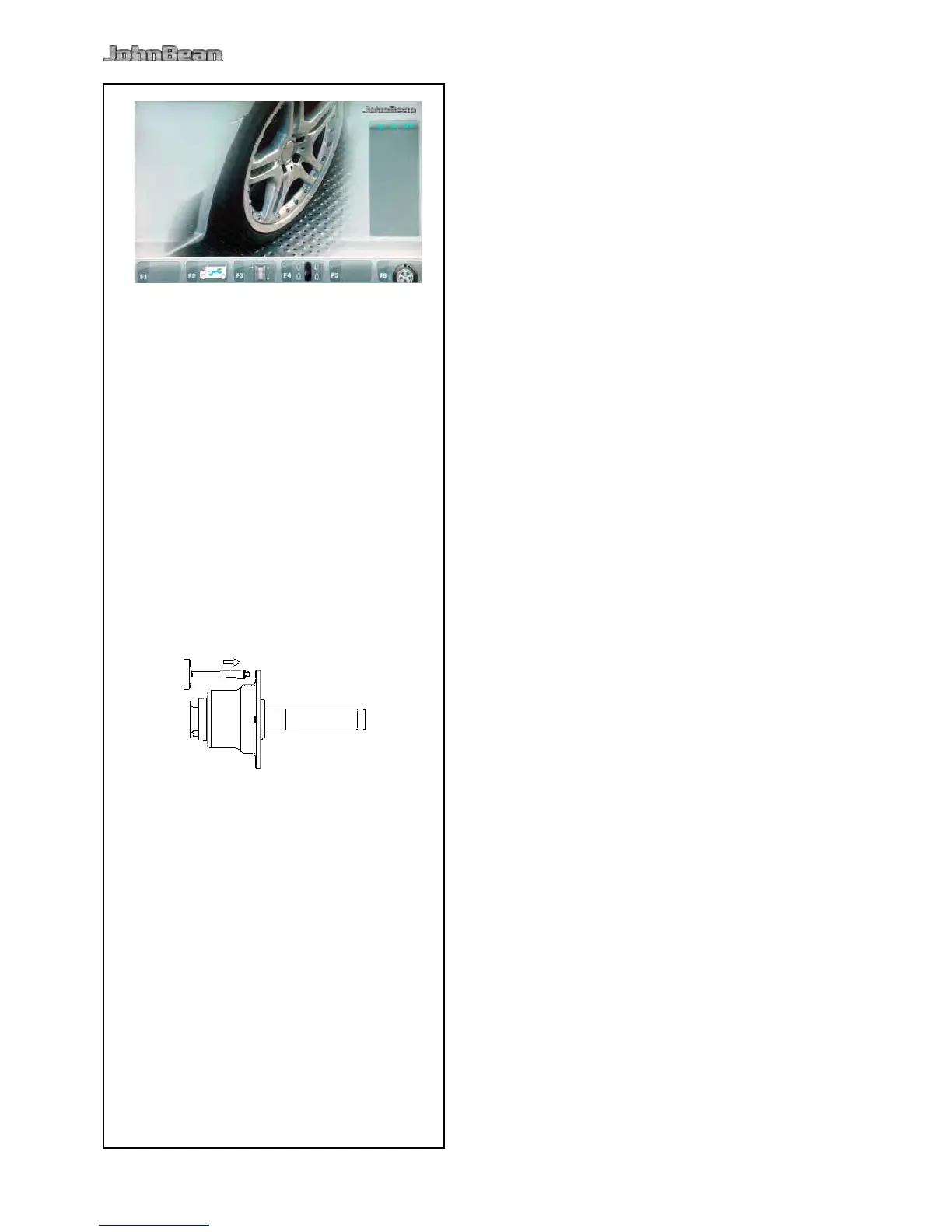

Screw the Calibration weight onto the threaded hole

in the wheel support ange (Figure 6-6).

Press the START key and launch a second

calibration run (to detect correction values).

After the second run the electronic control unit

processes the values taken during the calibration runs

and writes them in the permanent memory. When

this has nished an audible 3-tone signal is heard to

indicate that User Calibration has terminated.

Unscrew the Calibration weight from the ange and

put it back in its designated place in the Weight

Holder Tray.

Press the ESC key to return to the INTRODUCTION.

Loading...

Loading...