Important: Utiliser ce appareil uniquement en

tant que dispositif de contrôle de fonctionnement.

Lorsqu'une défaillance ou un dysfonctionnement

du appareil risque de provoquer des blessures

ou d'endommager l'équipement contrôlé ou un

autre équipement, la conception du système de

contrôle doit intégrer des dispositifs de protection

supplémentaires. Veiller dans ce cas à intégrer de

façon permanente d'autres dispositifs, tels que

des systèmes de supervision ou d'alarme, ou des

dispositifs de sécurité ou de limitation, ayant une

fonction d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du appareil.

Important:

• Do not apply power to the device before you

complete and check connections. Short circuits

or improperly connected wires may result in

permanent damage to the equipment.

• Use copper conductors only. Make all wiring in

accordance with local, national, and regional

regulations.

• The device is a low-voltage device. Do not exceed

the device electrical ratings. If you apply a high

voltage to the device, it voids any warranties and

may result in permanent damage.

• Do not remove the terminal block keys.

The terminal block plugs and the terminal

sockets are keyed to fit together in the correct

configuration only.

• Prevent any electrostatic discharge (ESD) to the

device. Static electric discharge can damage the

device and void any warranties.

Follow these guidelines when you wire the device:

• Route the supply power wires and communication

cables at least 50 mm (2 in.) away from the vent slots

in the sides of the device housing.

• Provide slack in the wires and cables. Keep cables

routed neatly around the device to promote good

ventilation, LED visibility, and ease of service.

• Ensure that the building automation network wiring

meets the specifications, rules, and guidelines in

Wiring considerations and guidelines.

• Follow the transformer manufacturer’s instructions

and the project installation drawings. Power supply

wire colors may be different on transformers not

manufactured by Johnson Controls

®

.

• Verify that transformer phasing is uniform across

the devices. Powering network devices with uniform

24 VAC supply power phasing reduces noise,

interference, and ground loop problems.

• Do not connect the device to an earth ground

connection.

Method for tightening terminal blocks

If you over-torque the terminal block screws during

installation of the device, the pole gap in the terminal

block may increase and create a loose connection. This

can affect any of the terminal blocks. Torquing the

terminal screws while the terminal blocks are attached to

the pin can damage the contact and can also cause loose

connections.

To prevent over-torquing and damage to the contacts:

Note: It is best practice to remove the connector

block from the pin headers on the unit before wiring

the terminal blocks. The best way to prevent any

contact damage and loose connections is to avoid

torquing the terminal screws while the plugs are

attached to the pin headers.

1. If available, use a torque screwdriver to tighten the

screw to .25 NM (2.212 in. lbs.). The recommended

bit size for the universal screws on the terminal

blocks is a slotted 1/8 in. (3 mm) bit.

2. If a torque screwdriver is not available, tighten the

terminal screws until the screw is snug on wire, and

then tighten the screw an additional quarter (90°)

to half (180°) turn.

Note: The design of the terminal block screw

helps to prevent over torque. Do not attempt

to tighten by using more down force than

necessary.

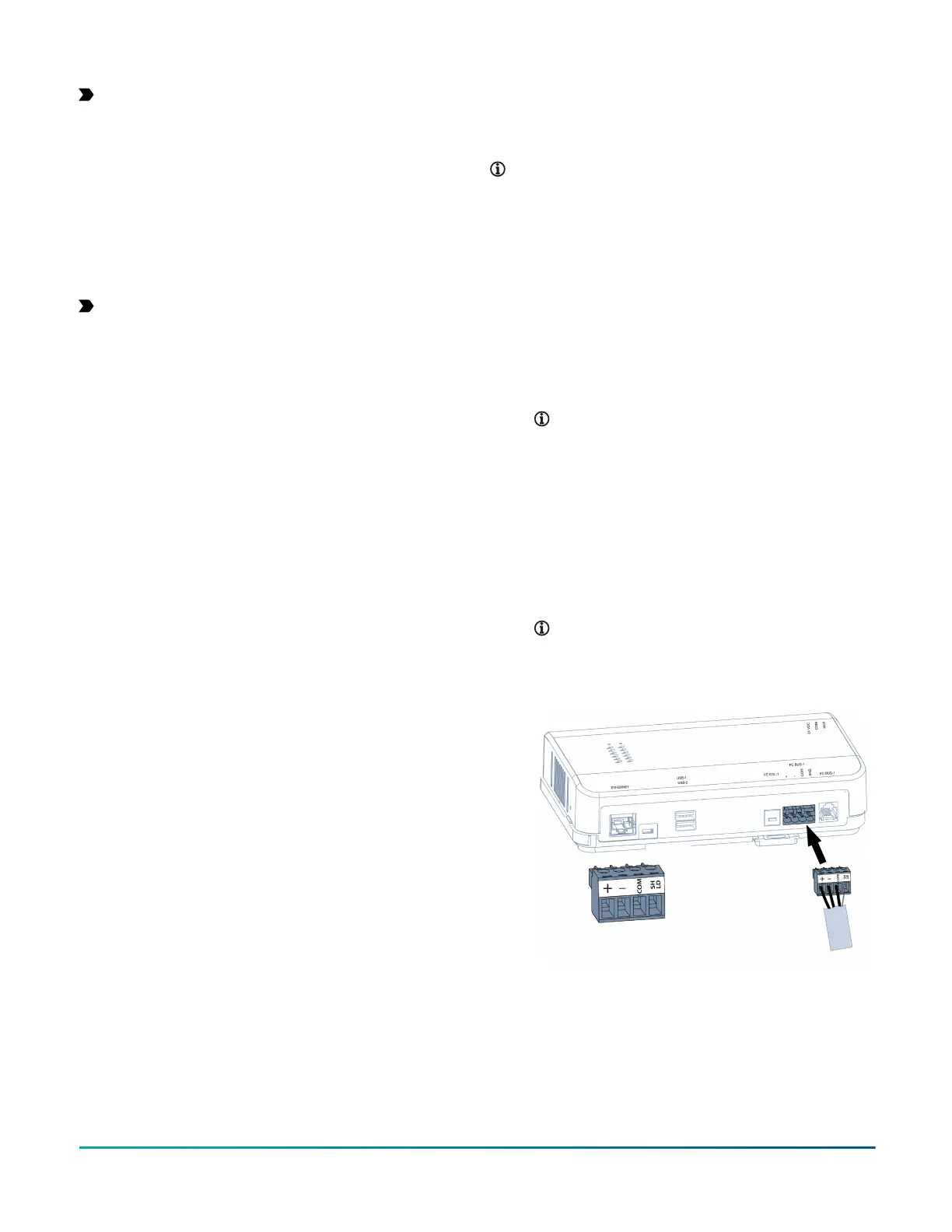

Connecting MS/TP devices

Supported field bus integrations include BACnet MS/TP

bus. The device has one field bus connection.

1. Connect the 3-wire bus cable to the removable 4-

terminal plugs labeled FC BUS-1 as shown in Figure

4.

Note: The FC bus terminal blocks on the

device are blue.

Figure 4: FC bus terminal blocks and wiring

connections

JC-RTR11002-0 BACnet Router Installation Guide4

Loading...

Loading...