6139716-UIM-A-0422

6 Johnson Controls Ducted Systems

Note: Applications shown are with XAH indoor coils that do not contain

a horizontal right hand extension pan.

Duct flanges

Duct flanges are integrated into the casing. Fold the flanges into posi-

tion and use screws to anchor the flanges.

Unit connections

There are several ways to handle the supply and return air duct connec-

tions. The location and sizing of the connections depends on the situa-

tion and the method best suited to the installation. Upflow, horizontal or

downflow applications may be used.

Use a transition to match unit opening to correctly size the supply air

duct. See Table 1 for air handler unit inlet and outlet dimensions.

Ductwork that is not designed to match the supply air opening can

cause turbulence inside the plenum. This turbulence can change the

airflow patterns across the electric heater limit switch/switches. If the

factory suggested transition cannot be fabricated, attach a block off

plate (approximately 8 in. high and running the full width of the plenum)

to the supply opening. See Figure 10. The use of this block off plate

enables better air circulation across the limit switches.

Air filters

.

Return air filters are required and must be field supplied. Filtration must

be accomplished external to the unit.

Section V: Electric heater installation

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

Use only 8HK heater kits, as listed on the air handler name plate and in

these instructions. Use data from Table 4 to Table 13 for information on

the required minimum motor speed tap to use for heating operation and

the maximum over-current protection device required as listed for com-

bination of air handler and heater kit.

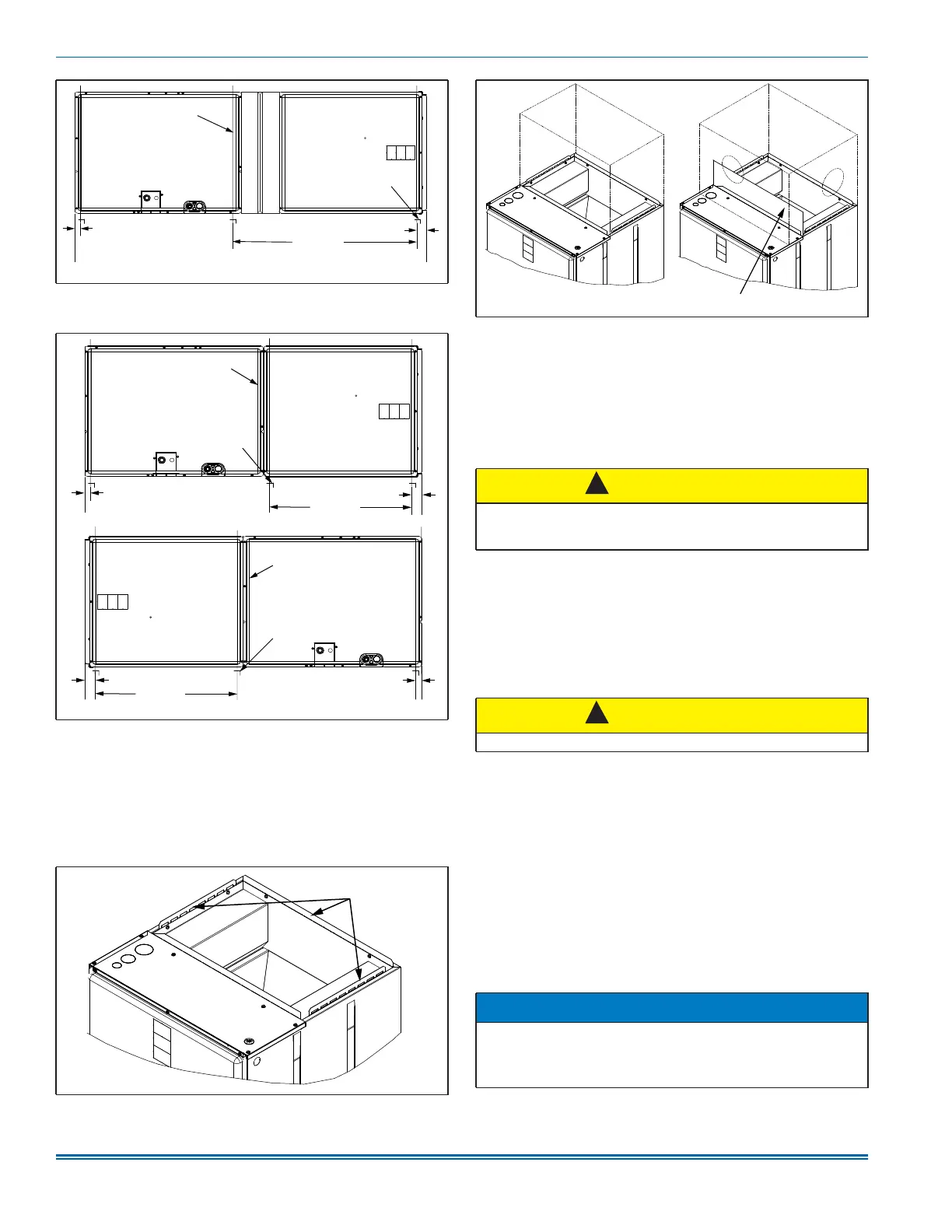

Figure 7: Suspension support locations for horizontal applications that

require the drain pan extension

Figure 8: Suspension support locations for horizontal applications that

do not require the drain pan extension

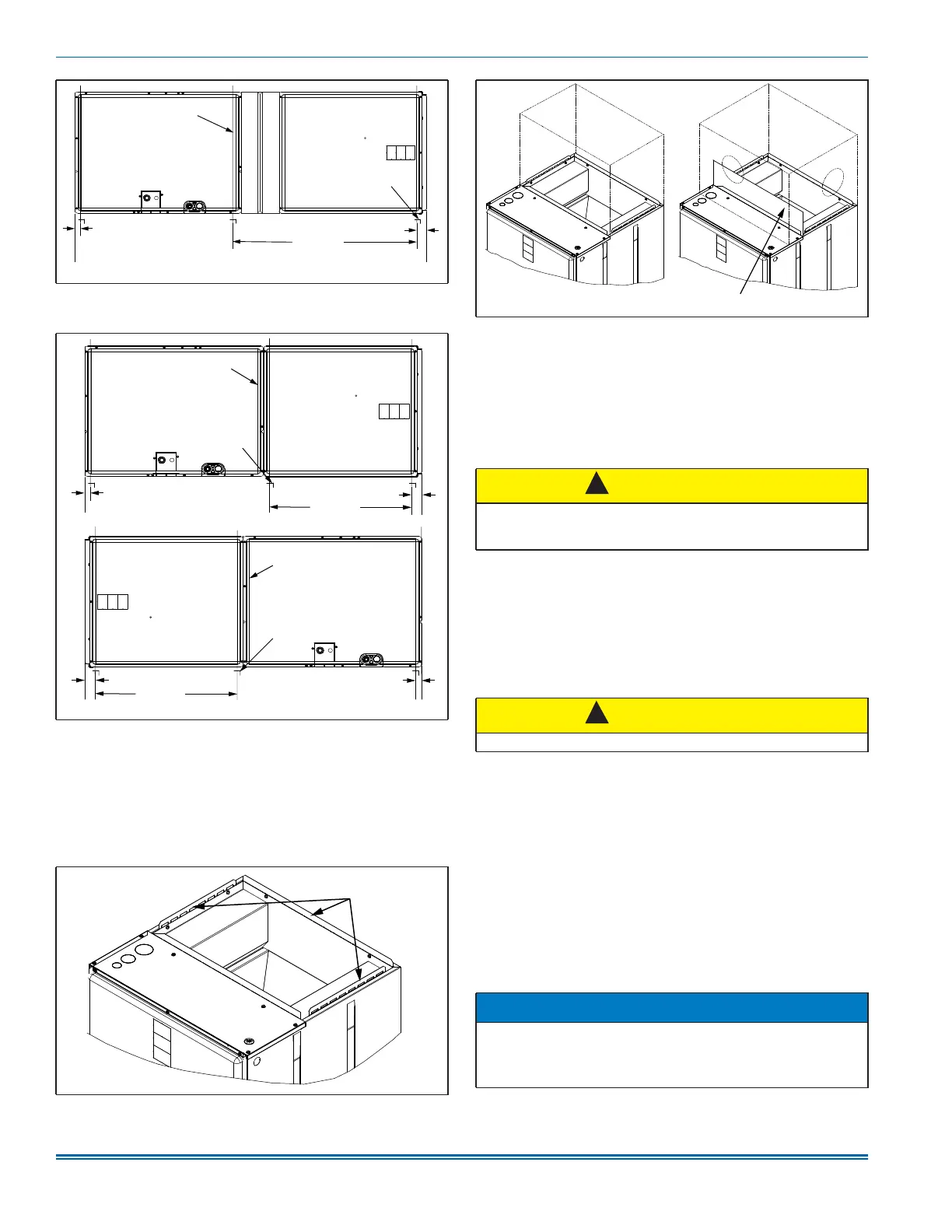

Figure 9: Duct attachment

A1769-001

28 3/4 in.

1 1/2 in.

1 in.

Minimum 3/8 in.

threaded rod

Minimum

1 1/2 in. x 1 1/2 in.

(Angle recommended

length 26 in. minimum with

2 in. clearance on both

sides of the air handler)

A1771-001

21 3/4 in.

1 1/2 in.

1 in.

Minimum 3/8 in. threaded rod

Minimum 1 1/2 in. x 1 1/2 in.

(Angle recommended length 26

in. minimum with 2 in. clearance

on both sides of the air handler)

1 in.1 1/2 in.

21 3/4 in.

Minimum 3/8 in. threaded rod

Minimum 1 1/2 in. x 1 1/2 in.

(Angle recommended length 26

in. minimum with 2 in. clearance

on both sides of the air handler)

A1696-001

Duct flanges

Figure 10: Ductwork transition

CAUTION

Use 1/2 in. screws to connect ductwork to the unit. Longer screws

may pierce the drain pan and cause leakage. If drilling pilot holes, drill

only though the field duct and the unit bottom duct flange.

CAUTION

Never operate the equipment without filters.

NOTICE

In some horizontal applications, the service disconnects on the elec-

tric heat kits must be rotated 180° so the up position of the discon-

nect is the ON position. This service disconnect orientation change is

required by UL 60335-2-40 (in reference to all circuit breakers).

A1697-001

Suggested location of block off plateRecommended transition

!

!

Loading...

Loading...