6139716-UIM-A-0422

Johnson Controls Ducted Systems 7

Section VI: Line power connections

Power can be brought into the unit through the supply air end of the unit

(top left when unit is vertical) or the left side panel. Use the hole appro-

priate to the unit’s orientation in each installation to bring the conduit

from the disconnect.

The power lead conduit must be terminated at the electrical control box.

See Table 10 to Table 13 and the latest edition of the National Electric

Code, or in Canada the Canadian electrical Code, and local codes to

determine correct wire sizing.

To minimize air leakage, seal the wiring entry point on the outside of the

unit.

All electrical connections to air handlers must be made with copper con-

ductors. Direct connection of aluminum wiring to air handlers is

not approved.

If aluminum conductors are present, all applicable local and national

codes must be followed when converting from aluminum to copper con-

ductors prior to connection to the air handler.

The chosen conductor and connections must all meet or exceed the

amperage rating of the overcurrent protector (service disconnect or

fuse) in the circuit.

Existing aluminum wire within the structure must be sized correctly for

the application according to the National Electric Code and local codes.

Use caution when sizing aluminum rather than copper conductors, as

aluminum conductors are rated for less current than copper conductors

of the same size.

Section VII: Low voltage control

connections

The 24 V power supply is provided by an internally wired low voltage

transformer that is standard on all models. If connecting the unit to a

208 V power supply, the low voltage transformer must be rewired to the

208 V tap. See the Wiring diagram.

Field supplied low voltage wiring can exit the unit through the top right

(when unit is vertical upflow) or the right side panel. See Figure 2.

Remove the knockout and pierce the foil faced insulation to allow wiring

to pass through.

Use as small of a hole as possible to minimize air leakage. Install a 7/8

in. plastic bushing in the selected hole and keep low voltage wiring as

short as possible inside the control box.

To further minimize air leakage, seal the wiring entry point at the outside

of the unit. Connect the field wiring at the pigtails supplied with the air

handler. See Figure 14 to Figure 22 for system wiring.

Section VIII: Blower speed connections

Adjust the blower motor speed to provide airflow within the minimum

and maximum limits approved for indoor coils, electric heat, and out-

door units. Make speed tap adjustments at the motor terminal block.

See Table 14 for airflow data. Connect the motor wires to the motor

speed tap receptacle for the speed required.

WARNING

Before obtaining access to terminals, all supply circuits must be dis-

connected.

WARNING

A fused disconnect switch must be field provided for the unit to be in

compliance with UL 60335-2-40 Clause 7.12.2.

!

!

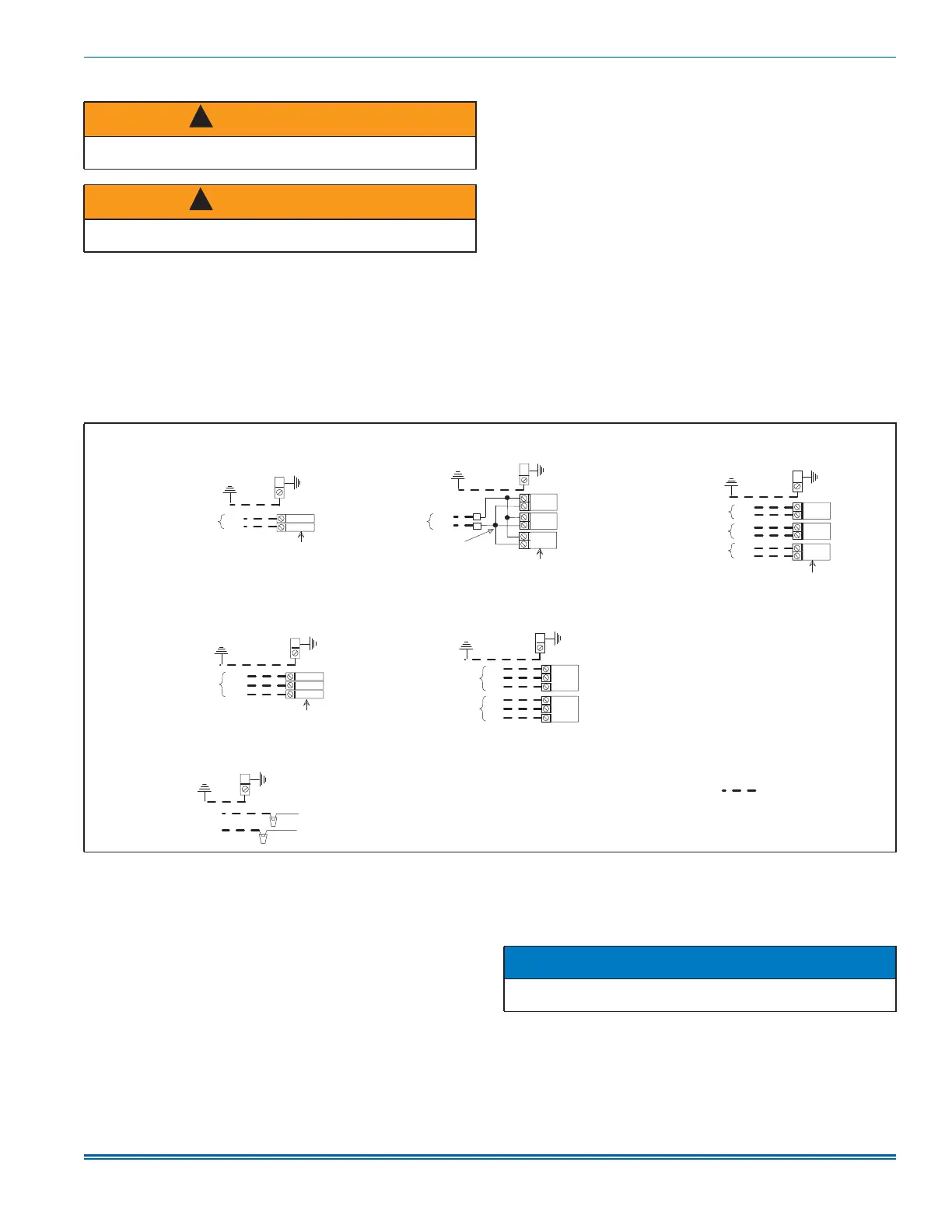

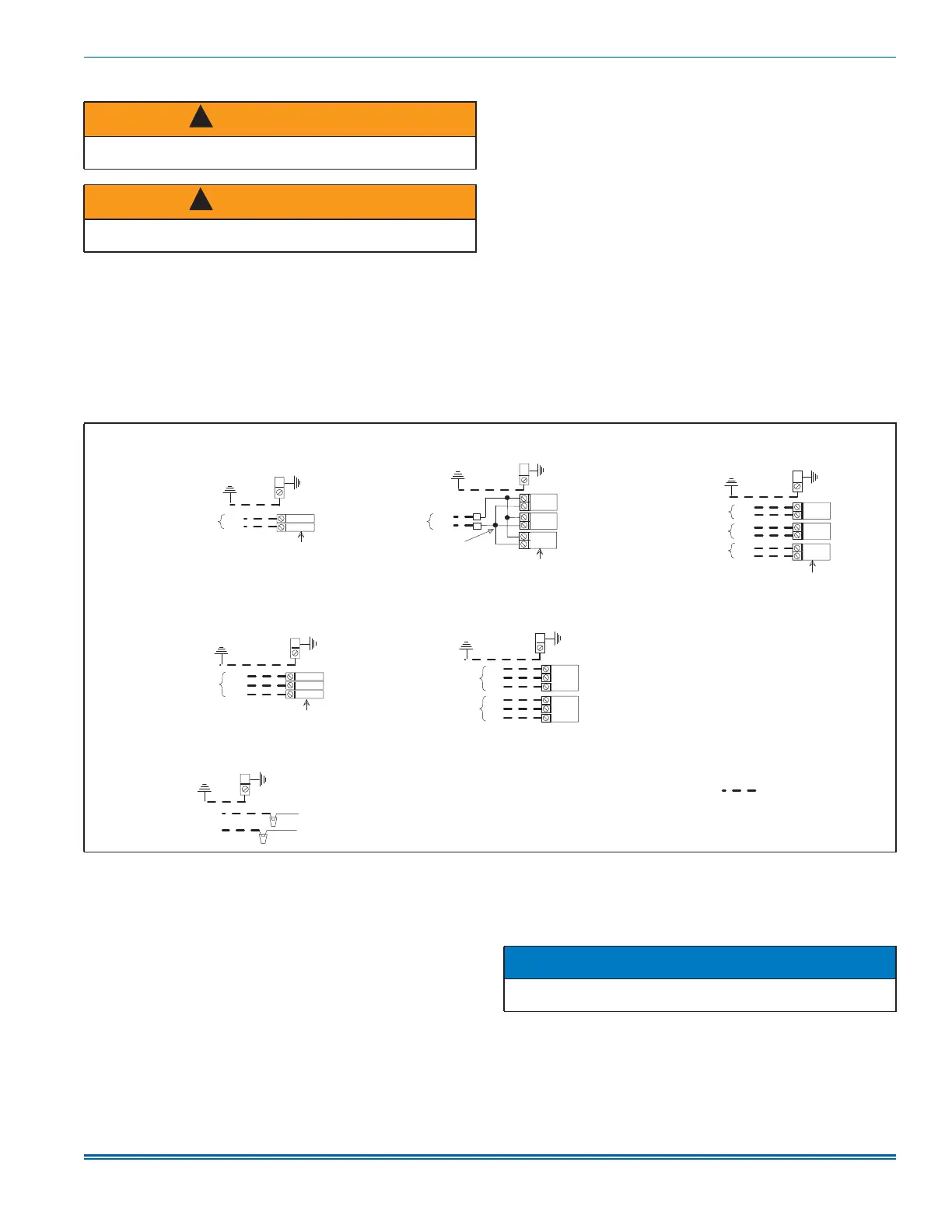

Figure 11: Line power connections

.

A1699-001

3

2

1

GND

SD

SD

SD

GND

GND

CKT

L1

L2

L1

L2

SD

SD

SD

CKT

CKT

2

1

L1

L2

L3

L1

L2

L3

L1

L2

L3

GND

CN

CN

CKT

CKT

SD

SD

GND

GND

L1

L2

L1

L2

L1

L2

Two circuits on 15 kW to 20 kW

Three circuits on 25 kW

Field power wiring

(208/230 V)

Component Codes:

GND - Ground lug

SD - Service disconnect

CKT - Circuit

CN - Wire connector/nut

1 Phase Electric Heat Power Options:

3 Phase Electric Heat Power Options:

Single source power

Power supply Power supply Power supply

Terminal block or service disconnect

Jumper bar

Two circuits on 15 kW to 20 kW

Three circuits on 25 kW

Multi-source power with jumper bar Multi-source power

No Electric Heat:

Power supply

Single source power Multi-source power

Power supply

Terminal block or service disconnect

Power supply

NOTICE

All wiring must comply with local and national electrical code require-

ments. Read and heed all unit caution labels.

Loading...

Loading...