Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

58/168

008831 en 2020.10

Technical description

It is imperative that an uninterrupted supply of high-pressure liquid refrigerant is provided to

the injection system at all times. Two items are of extreme importance, the design of the re-

ceiver/liquid injection supply and the size of the liquid line.

It is recommended that the receiver is oversized sufficiently to retain a five minute supply of re-

frigerant for oil cooling. The evaporator supply must be secondary to this consideration. Two

methods of accomplishing this are shown below.

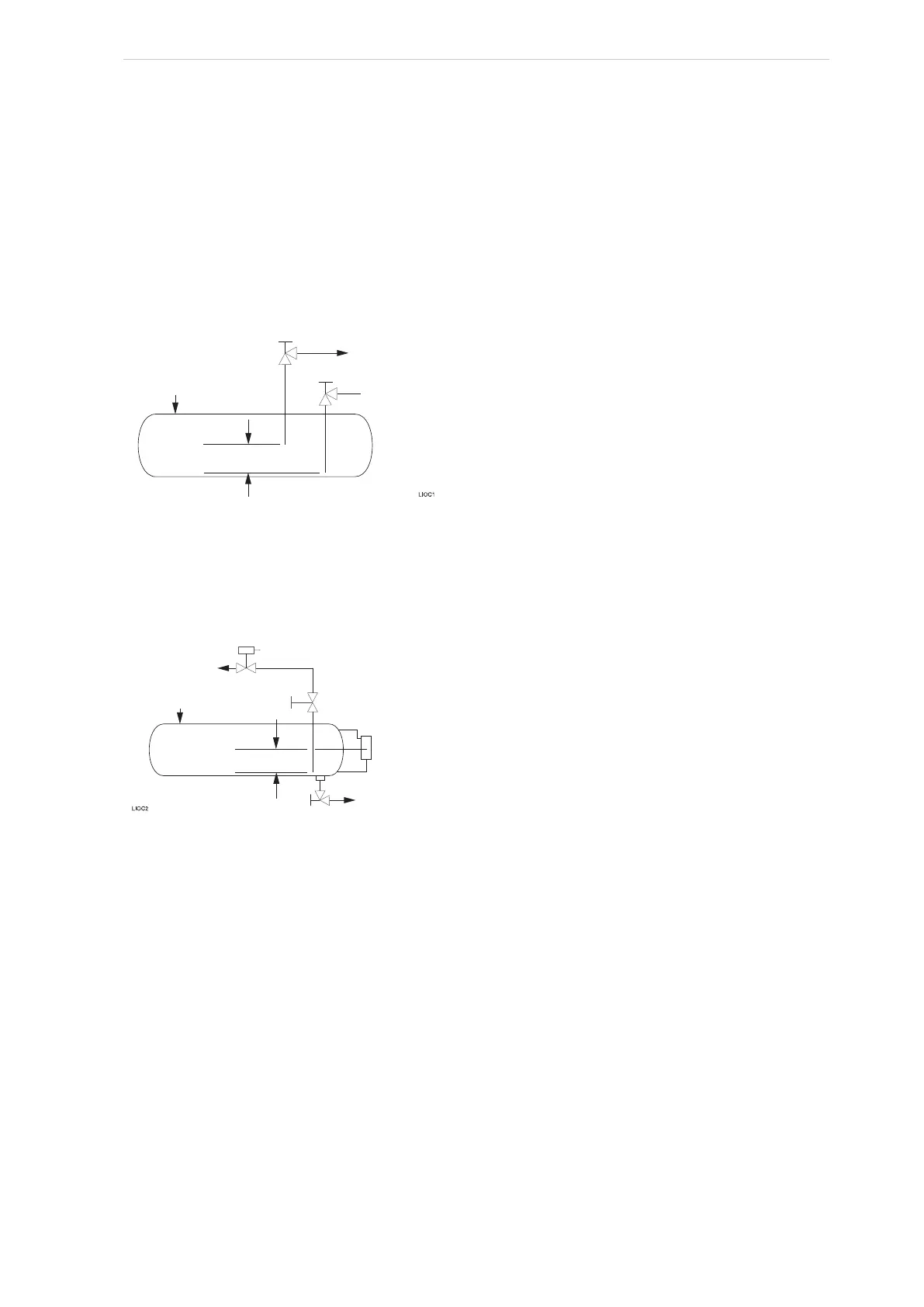

The dual dip tube method, Fig. 35, uses two dip tubes in the receiver. The liquid tube is below the

evaporator tube to ensure continued oil cooling when the receiver level is low.

Fig. 35: Dual dip tube method

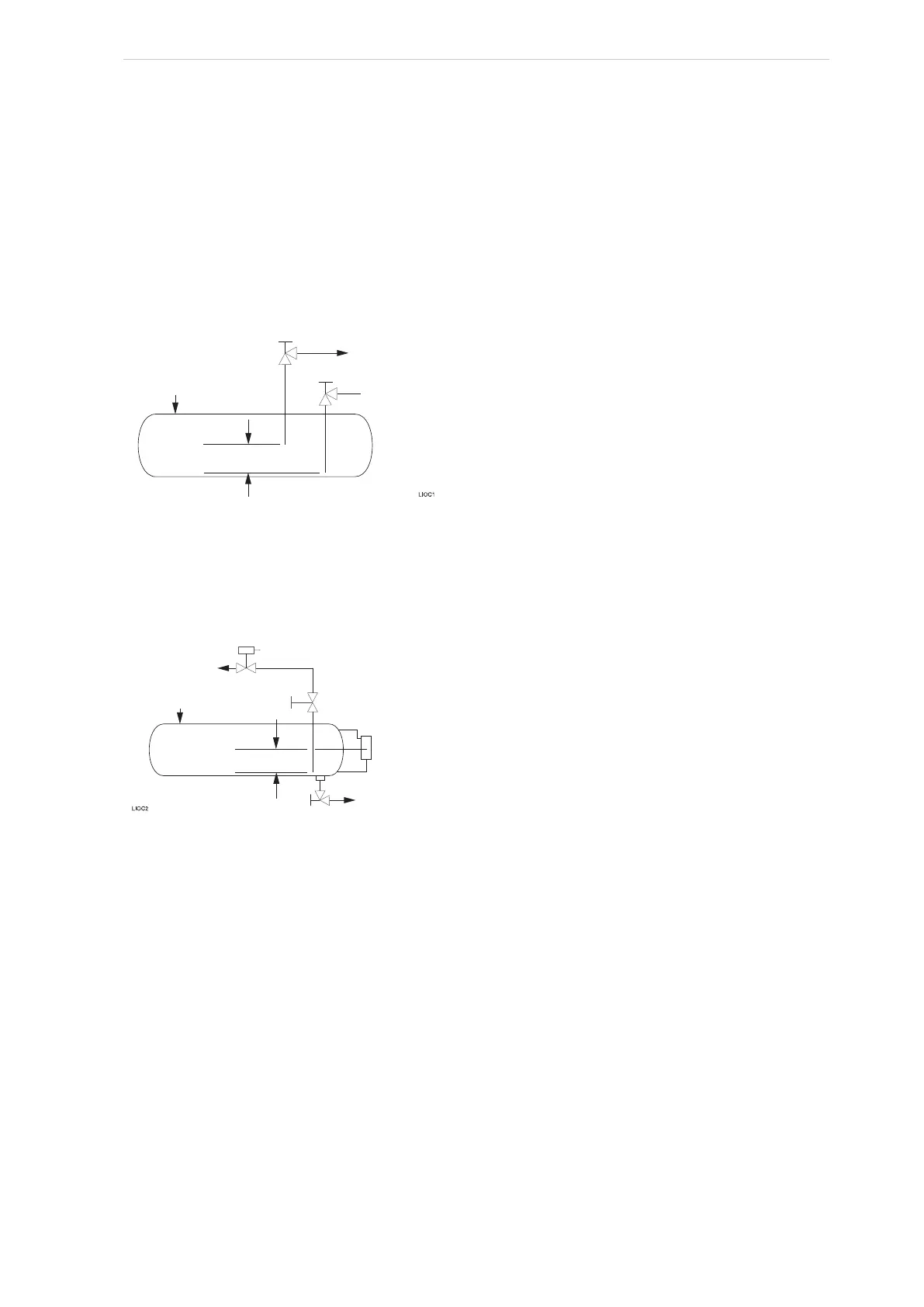

The level control method, Fig. 36, uses a float level control on the receiver to close a solenoid

valve feeding the evaporator when the liquid falls below the amount necessary for five minutes of

liquid injection oil cooling.

Fig. 36: Level control method

Liquid line sizes and the additional receiver volume (quantity of refrigerant required for 5 minutes

of liquid injection oil cooling) are given in Table 6.

To evaporator

To compressor

oil c

ooling system

From condenser

Receiver

Locate to provide

5 min. liquid supply

To evaporator

From condenserKing valve

Low level

floa

t switch

To compressor

oil c

ooling system

Locate to provide

5 min. liquid supply

Loading...

Loading...