System 450™ Series Control Modules with Relay Outputs Installation Instructions12

Setting Up an Analog Output for Standard Control

or High Input-Signal Selection Control

Analog outputs provide an analog signal to control

equipment in you application based on the input from a

standard fixed setpoint sensor (Sn-1, Sn-2, or Sn-3) or

a High Input Signal Selection sensor (HI-2 or HI-3).

Note: The differential sensor, Sn-d, is used to set up

analog and relay outputs for Differential Control. See

Setting

Up an Output for Differential Control on page

16 for more information.

Analog outputs provide an auto-selecting analog signal

that is proportional to the sensed input condition. The

System 450 analog output senses the impedance of

the controlled equipment’s analog input circuit and

automatically delivers either a 0–10 VDC or 4–20 mA

signal to the controlled equipment.

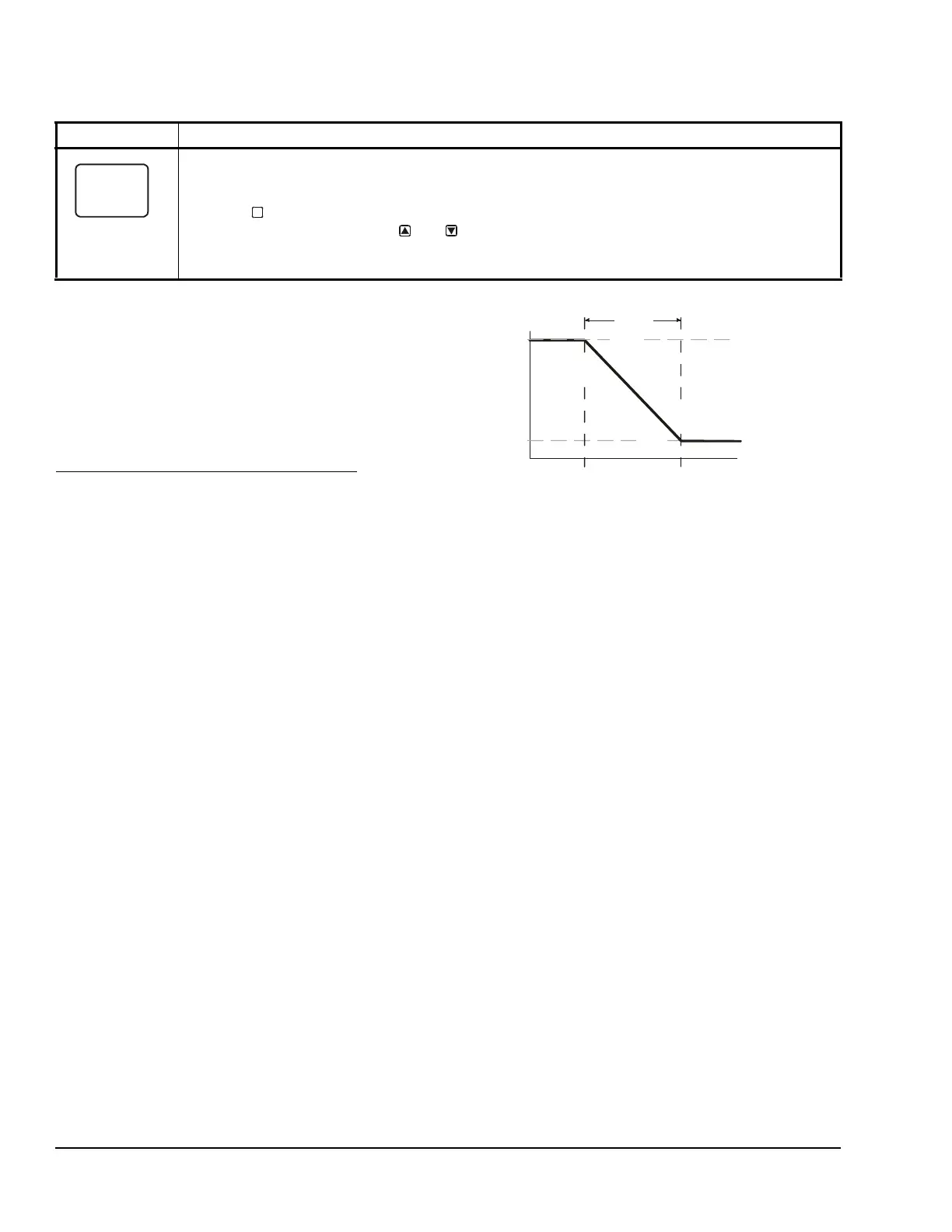

Figure 6 shows an example of the analog output setup

values and the resulting output signal in a typical space

heating application (SP > EP and OSP < OEP).

The control action between the input signal and the

output signal can be set up four ways, depending on

the values selected for the Setpoint (SP), End Point

(EP), Percent Output Signal Strength at Setpoint

(OSP), and Percent Output Signal Strength at End

Point (OEP). The LCD displays different Control Ramp

icons for the four control actions.

Relay Output Setup Start Screen

After you have set up this Relay Output, you can go to another Output Setup Start screen, the Sensor

Setup Start screen, or return to the Main screens.

9. Press to scroll through the remaining Output Setup Start screens and return to the Sensor

Setup Start screen, or press and simultaneously to return to the System 450 Main

screens.

The screen example shows a Relay Output Setup Start screen for Output 1.

Table 6: System 450 Setup Screen Information and Procedures for Relay Outputs with Standard Control

and High Input-Signal Selection Control (Part 3 of 3)

LCD Screen Name, Description/Function, User Action, and Example

M

System Output

Condition Value

Less Greater

65°F

10%

70°F

SP > EP

SP = 70 ( )

EP = 65 ( )

OSP = 10 (%)

OEP = 100 (%)

OSP

SP

EP

Proportional

Band

Fig:sys450_cntrl_rmp_exmpl

Figure 6: Control Ramp Example for a Typical

Heating Application (SP > EP and OSP < OEP)

Loading...

Loading...