2. When the holding charge is completely discharged,

loosen and remove the Schrader valve core.

3. Place a backup wrench on the distributor, and

loosen and remove the brass distributor nut. Retain

the brass nut for use on the liquid line. Keep the

PTFE washer in place and discard the sealing disk.

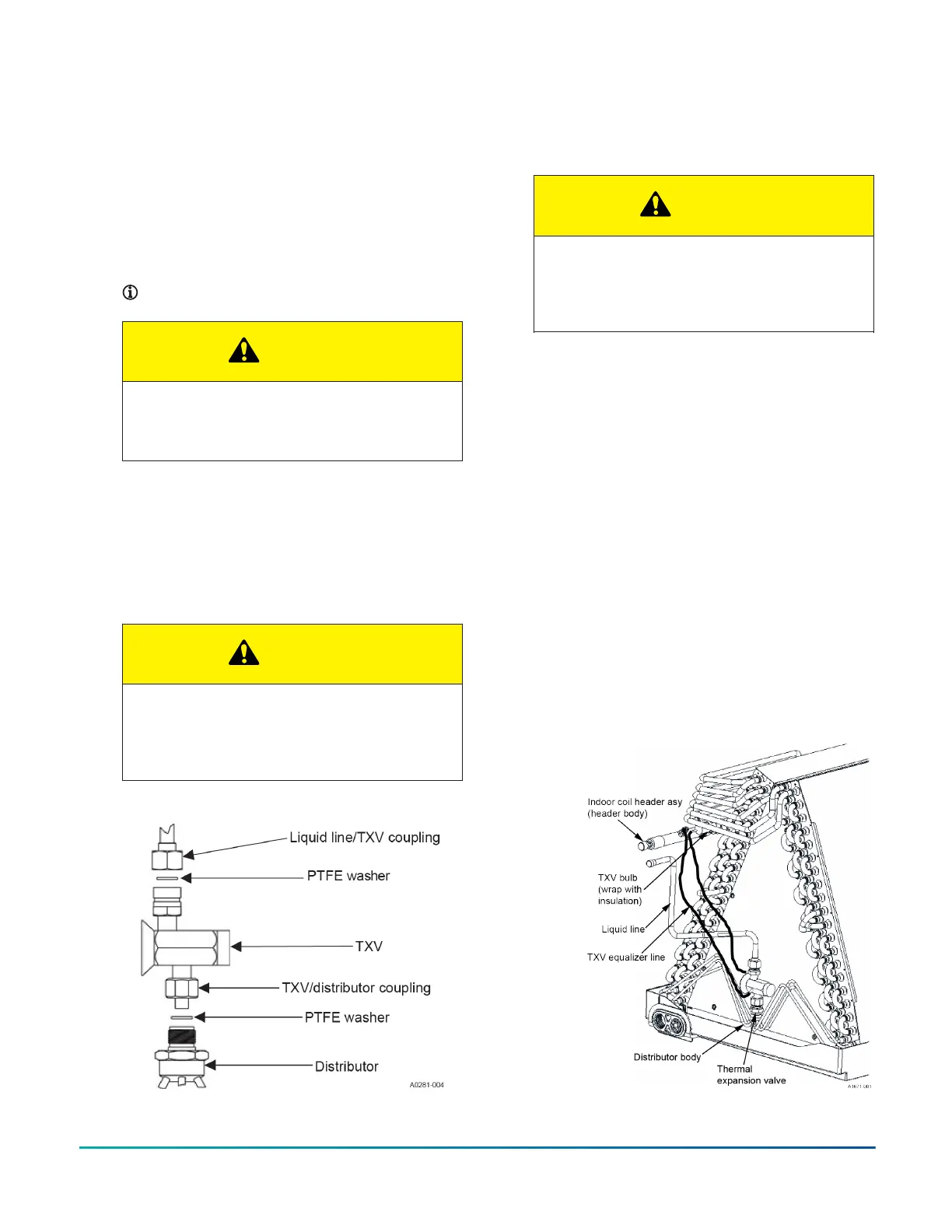

4. Install the TXV onto the distributor assembly with

the supplied fittings. Ensure the PTFE washer is

seated in the distributor. Hand tighten and turn an

additional 1/4 turn to seal. See Figure 8.

Note: Do not overtighten the fittings.

CAUTION

Do not over-tighten. Do not use slip joint pliers.

This distorts the aluminum distributor and the

brass fitting (potentially causing leaks).

5. Slide the nut removed in Step 3 over the supplied

liquid line. Place the supplied PTFE washer from

the TXV kit in place on the TXV and install the liquid

line to the top of the TXV. Adjust the distributor

assembly so the liquid line aligns with the hole in

the access panel. See Figure 8. Hand tighten the

liquid line and apply an additional 1/4 turn to seal.

CAUTION

The Schrader valve core must not be

installed into the suction line TXV equalizer

line fitting. Poor system performance or system

failure could result.

Figure 8: TXV installation

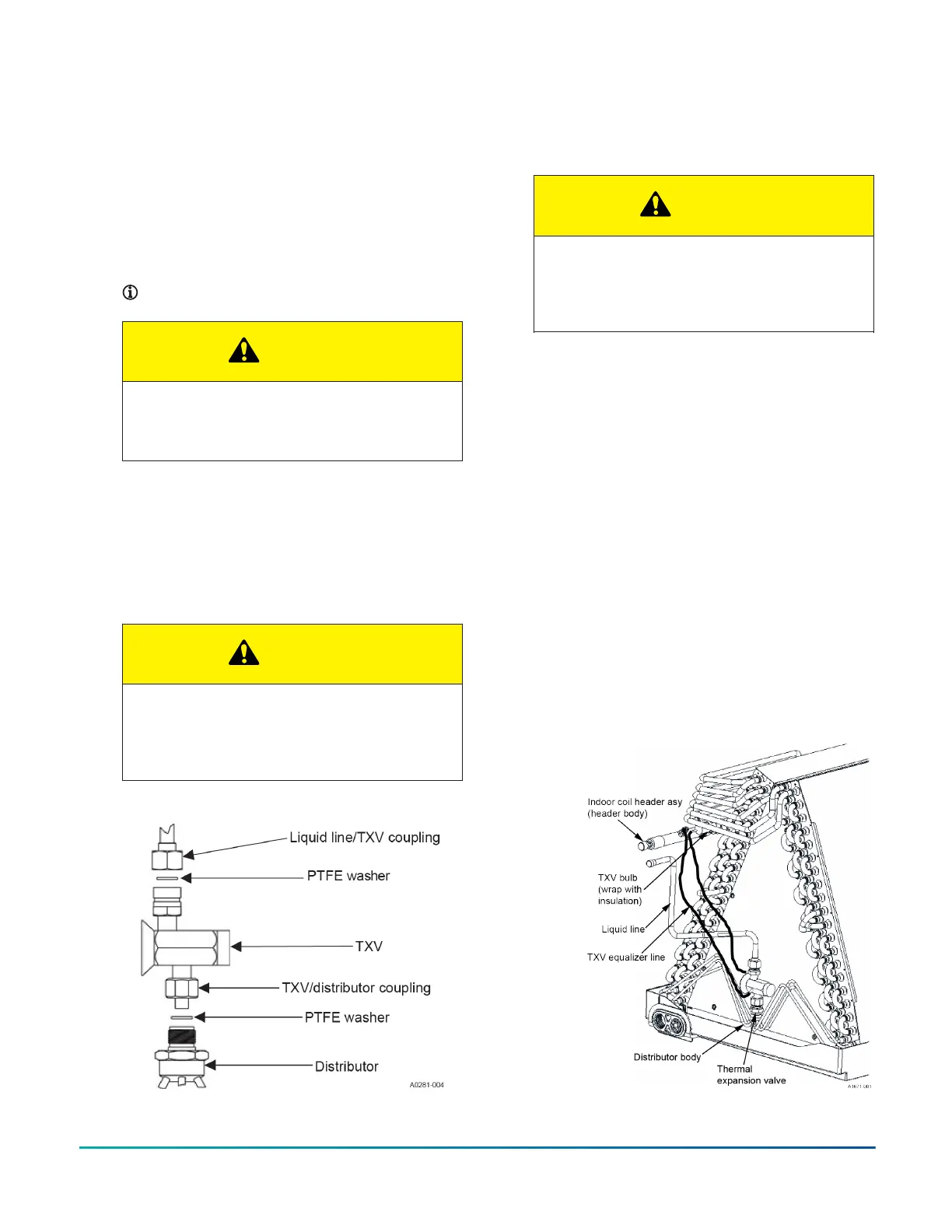

6. Install the TXV equalizer line onto the vapor line by

hand tightening the 1/4 in. SAE coupling nut to the

equalizer fitting and apply an additional 1/3 turn to

seal. See Figure 9.

CAUTION

Mount the TXV temperature sensing bulb after

the vapor line is brazed and sufficiently cooled.

Failure to use a suction-line split grommet may

result in TXV failure.

7. Route the temperature sensing bulb tube for the

TXV toward the vapor line header and the TXV

equalizer tube connection port on the vapor line

header.

8. Install the TXV bulb to the vapor line near the TXV

equalizer tube connection port, using the bulb

clamps supplied with the TXV assembly. Ensure

that the bulb makes maximum contact. See Figure

9 and Figure 10 and adhere to the following:

a. Install the TXV bulb on the vapor line suction

header near the TXV equalizer tube connection

port. Ensure that the bulb is installed at a 10

o’clock or 2 o’clock position.

b. Insulate the TXV bulb using the thermal

insulation provided to protect it from the effect

of the surrounding ambient temperature. Cover

the bulb completely to insulate it.

9. When the refrigeration piping is installed, leak test

the system.

Figure 9: TXV bulb and equalizer line installation

Installation Manual: R-410A Outdoor Split-System Air Conditioner12

Johnson Controls Ducted Systems

Loading...

Loading...