1083163-UIM-J-0918

Johnson Controls Unitary Products 41

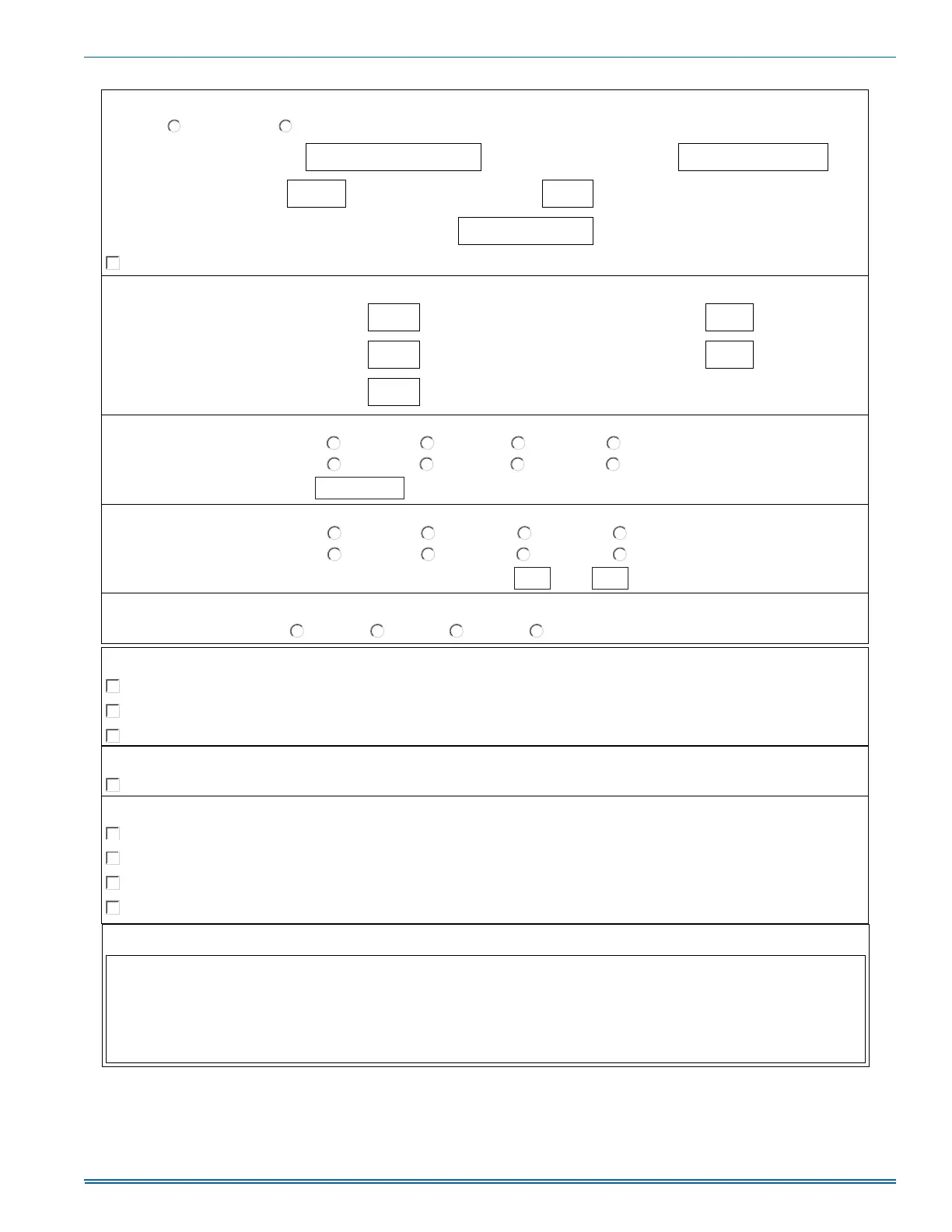

Natural Gas LP Gas (Requires LP conversion kit)

LP Conversion Kit Installed By

Supply static after evaporator coil (in w.c.")

Return Static (in w.c.") before lter

Total External Static Pressure

Installation debris disposed of and furnace area cleaned up?

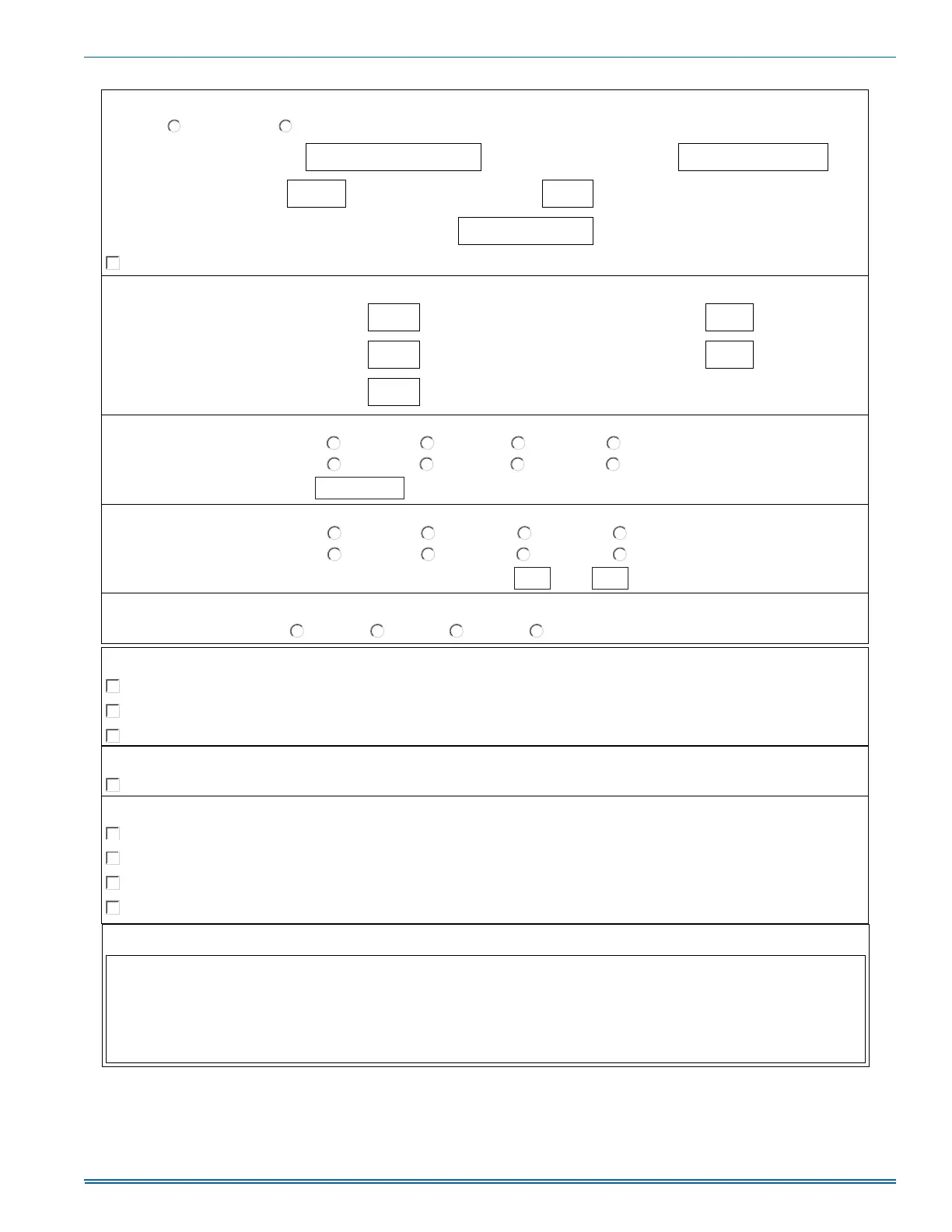

Explain operation of system to equipment owner

Explain the importance of regular lter replacement and equipment maintenance

Gas Side

Air Side: System External Static Pressure

Owner Education

Additional Job Detail

Supply static before evaporator coil (in w.c.")

Calculated input in btuh - clock the gas meter (Nat Gas Only)

Manifold Gas Pressure (in. w.c.")Inlet Gas Pressure (in. w.c.")

LP Gas Conversion Kit Part # Used

Burner ame inspected -- ames are blue and extending directly into the primary heat exchanger cells

Return Static (in w.c.") after lter (furnace side)

Air Side: Heating

Air Side: Cooling

Air Side: Continuous Fan

Clean Up

Give owner the owner's manual provided

Gas Type

Explain thermostat use and programming (if applicable) to owner

Cycle Test

Operate the furnace through several heating cycles from the thermostat, noting and correcting any problems

Operate the furnace through continuous fan cycles from the thermostat, noting and correcting any problems

Operate the furnace through cooling cycles (as applicable), noting and correcting any problems

Low Heat Blower Speed Selected

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

1 2 3 4 5

High Heat Blower Speed Selected

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5) 1 2 3 4 5

Temperature rise in degrees F

Low Cool Blower Speed Selected

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

1 2 3 4 5

High Cool Blower Speed Selected

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

1 2 3 4 5

Cooling CFM delivery (use Blower Performance Data Chart)

Hi Low

Blower Speed Selected

Lo Heat HI Heat Lo Cool

Hi Cool

Loading...

Loading...