ELECTRICAL

ELECTRIC STARTER SERVICING

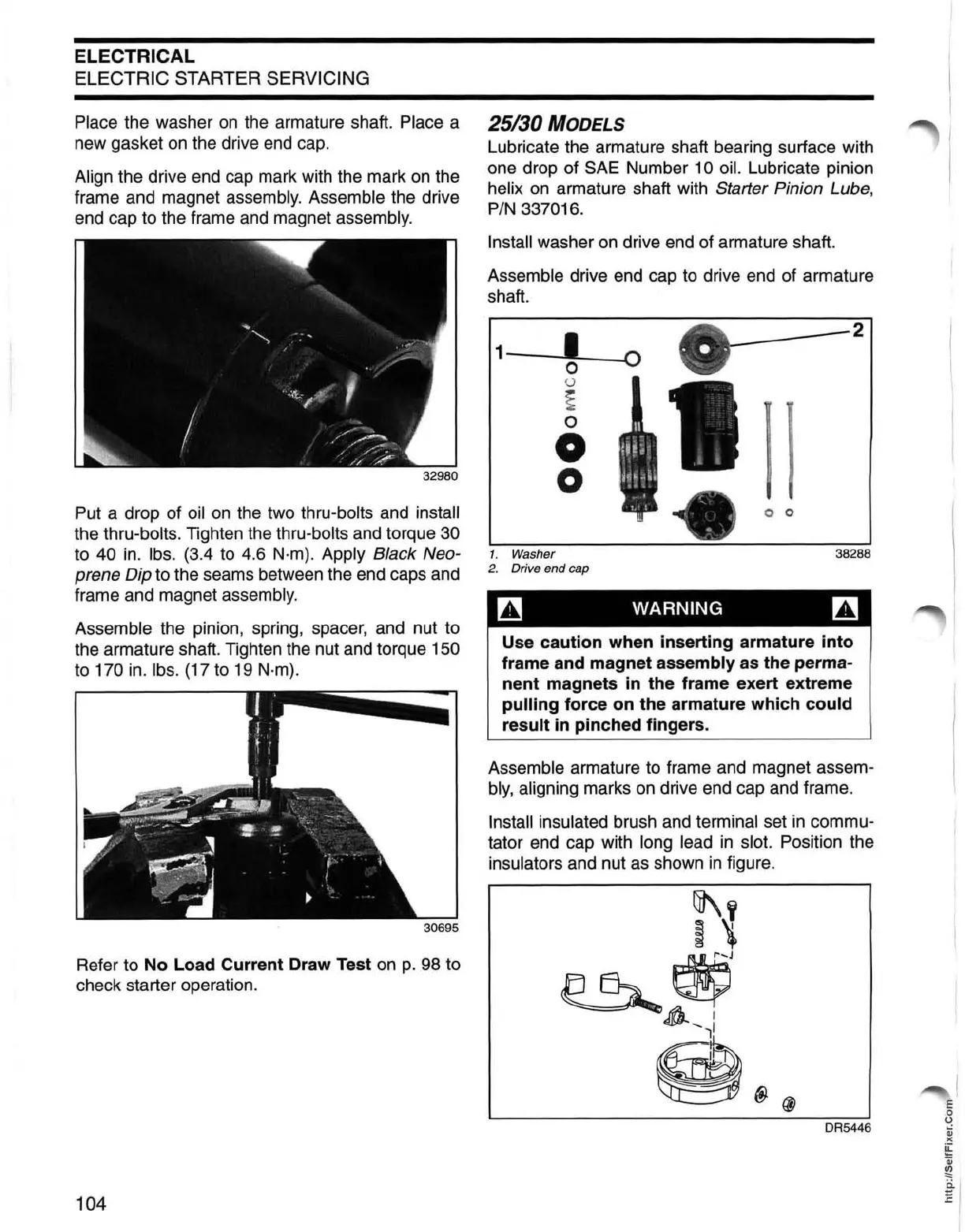

Place the washer

on

the armature shaft. Place a

new gasket on the drive end cap.

Align the drive end cap mark with the mark

on

the

frame and magnet assembly. Assemble the drive

end cap to the frame and magnet assembly.

Put a drop of

oil

on

the two thru-bolts and install

the thru-bolts. Tighten the thru-bolts and torque

30

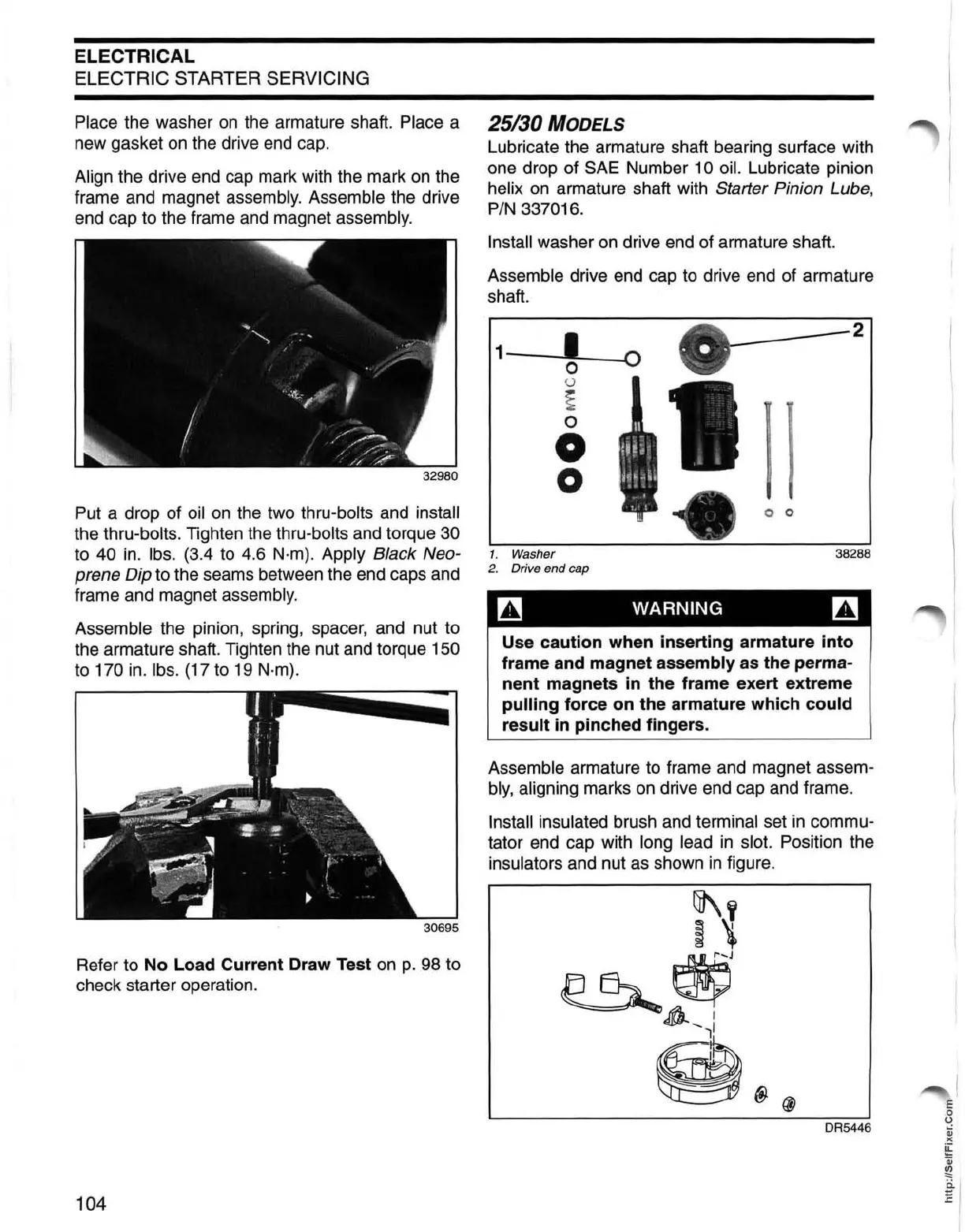

25/30 MODELS

Lubricate the armature shaft bearing surface with

one drop of SAE Number

10 oil. Lubricate pinion

helix

on

armature shaft with Starter Pinion Lube,

PIN

337016.

Install washer

on

drive end of armature shaft.

Assemble drive end cap to drive end of armature

shaft.

1_~I--O

o

<.)

~

o

o

o

O

~

___

--2

o 0

to 40

in.

Ibs. (3.4 to 4.6 N·m). Apply Black Neo- 1. Washer

38288

prene Dip to the seams between the end caps and 2. Drive end cap

frame and magnet assembly.

Assemble the pinion, spring, spacer, and nut to

the armature shaft. Tighten the nut and torque 150

to 170 in. Ibs. (17 to 19 N·m).

Refer to No Load Current Draw Test

on

p.

98 to

check starter operation.

104

m

WARNING

m

Use caution when inserting armature

into

frame and magnet assembly as the perma-

nent magnets in the frame exert extreme

pulling force on the armature which could

result in pinched fingers.

Assemble armature to frame and magnet assem-

bly,

aligning marks

on

drive end cap and frame.

Install insulated brush and terminal set

in

commu-

tator end cap with long lead

in

slot. Position the

insulators and nut as shown

in

figure.

DR5446

Loading...

Loading...