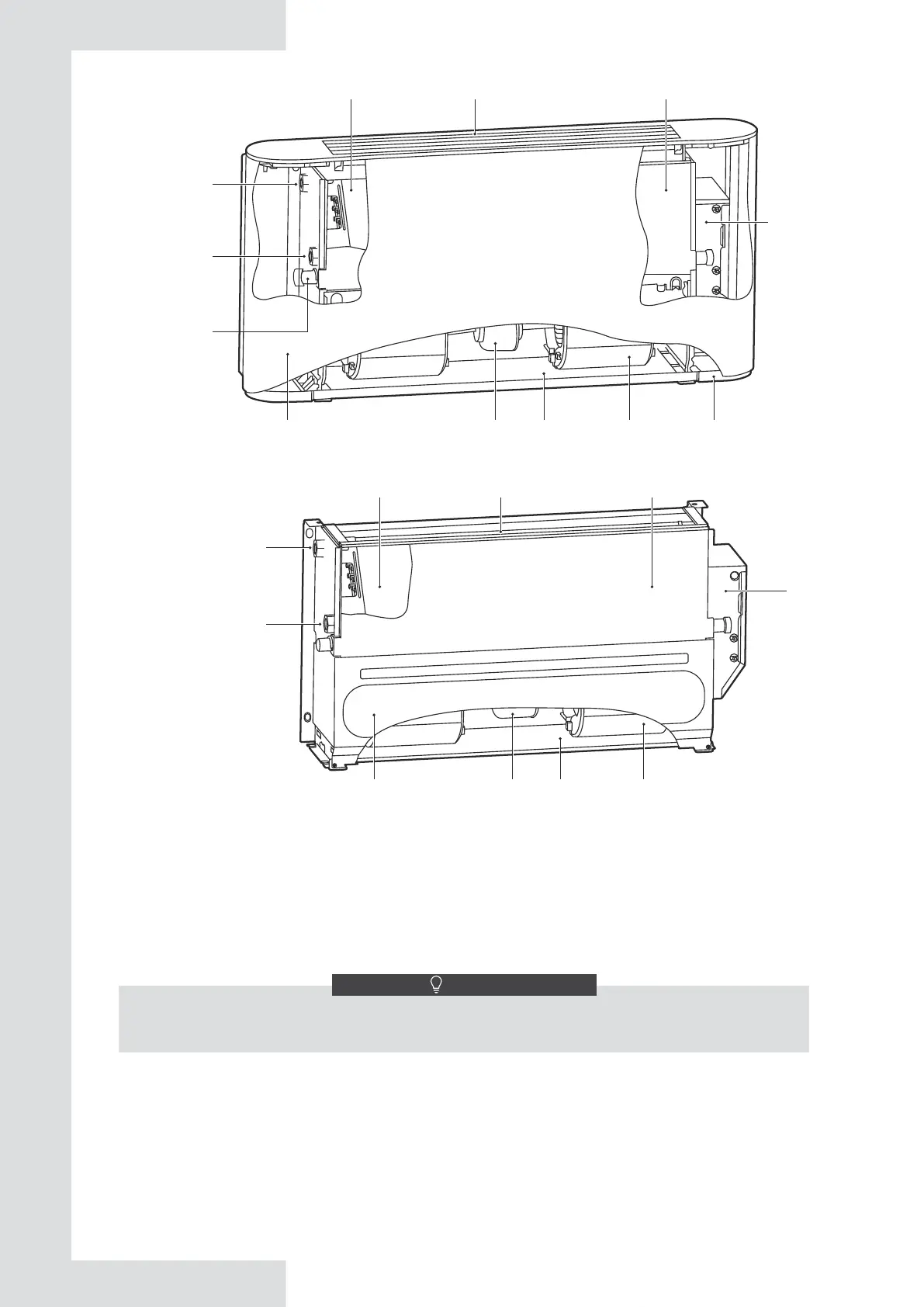

Figure 4-2 Diagram of unit (exposed)

4.2.2 Maintenance

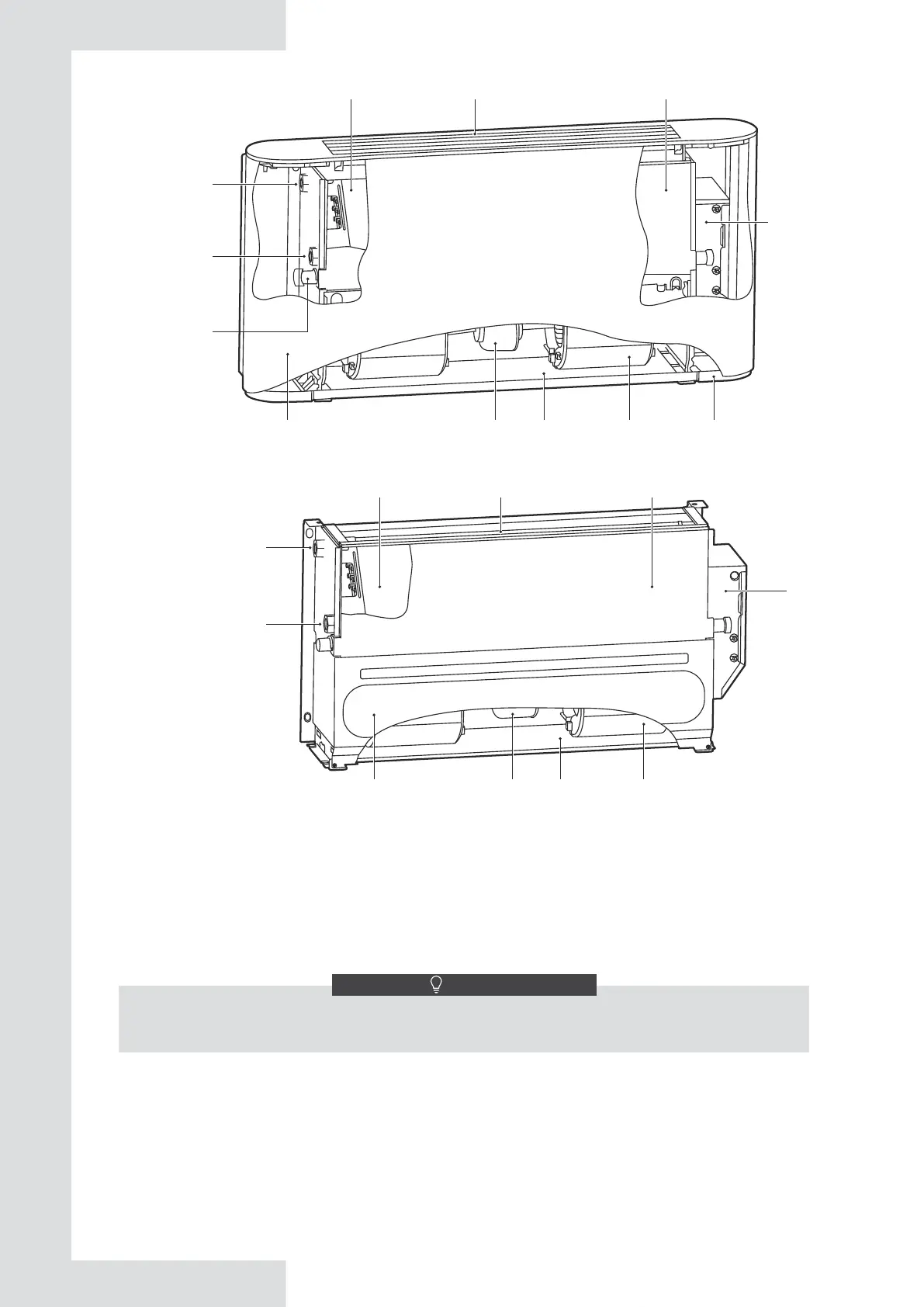

Figure 4-3 Diagram of unit (concealed)

NOTE

Only qualified technicians who have unit and refrigeration system experience can perform maintenance operation.

Proper gloves are required.

For dual-pipe system and four-pipe cold water coil, the water inlet and outlet joints are G3/4. For four-pipe hot water coil,the

water inlet and outlet joints are G1/2.

The casing of the unit is made of galvanized steel; the air filter is made of nylon fibre, and the aluminum alloy air filter can be

customized; the motor has internal overheat protection and overcurrent protection; a centrifugal rotating fan is used; a

soundproof material such as sponge is used; the fin type heat exchanger is composed of copper pipe and aluminum foil, and

the heat exchanger pipe connection can be changed on site.

Before maintenance or check, disconnect the unit from power supply, keep the main switch closed with warning sign attached,

to prevent others from resuming the power accidentally.

1) Routine maintenance

2) Once every month

Check whether the air filter is clean. The air filter is washable as it is made of fibre. When the unit is operational, make sure you

check the air filter every month.

3) Once every six months

Check whether the heat exchanger and condensate drain pipe are clean. After power disconnection, disassemble the unit to

check the heat exchanger and condensate drain pipe.

Heat exchanger Air outlet grille Drain pan

Electric

control

box

BaseFanFilterMotorCasing

Water

inlet

joint

Water

outlet

joint

Heat exchanger Air outlet grille Drain pan

Electric

control

box

FanFilterMotorReturn air cover

Water

inlet

joint

Water

outlet

joint

06

Drain

pipe

connection

Loading...

Loading...