−7 −

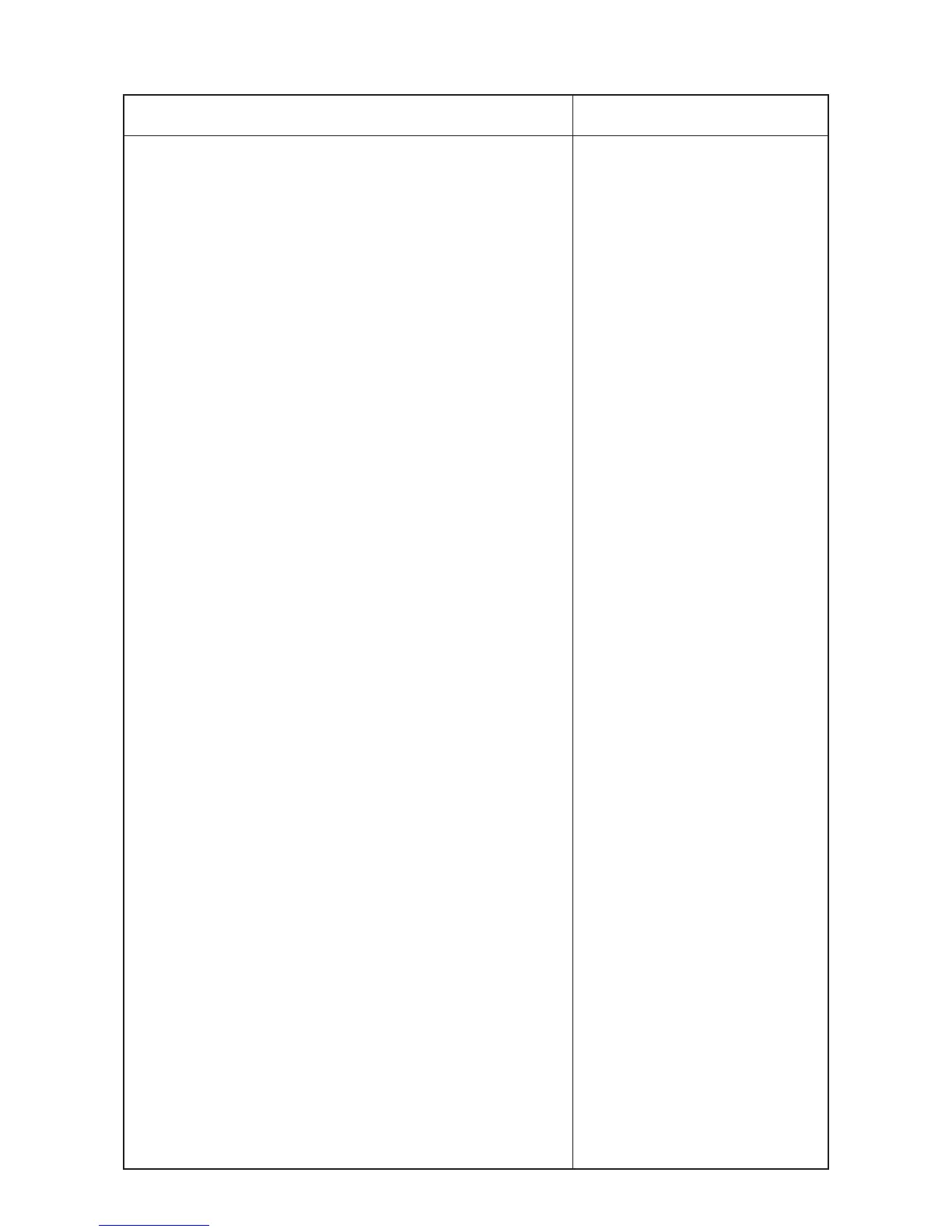

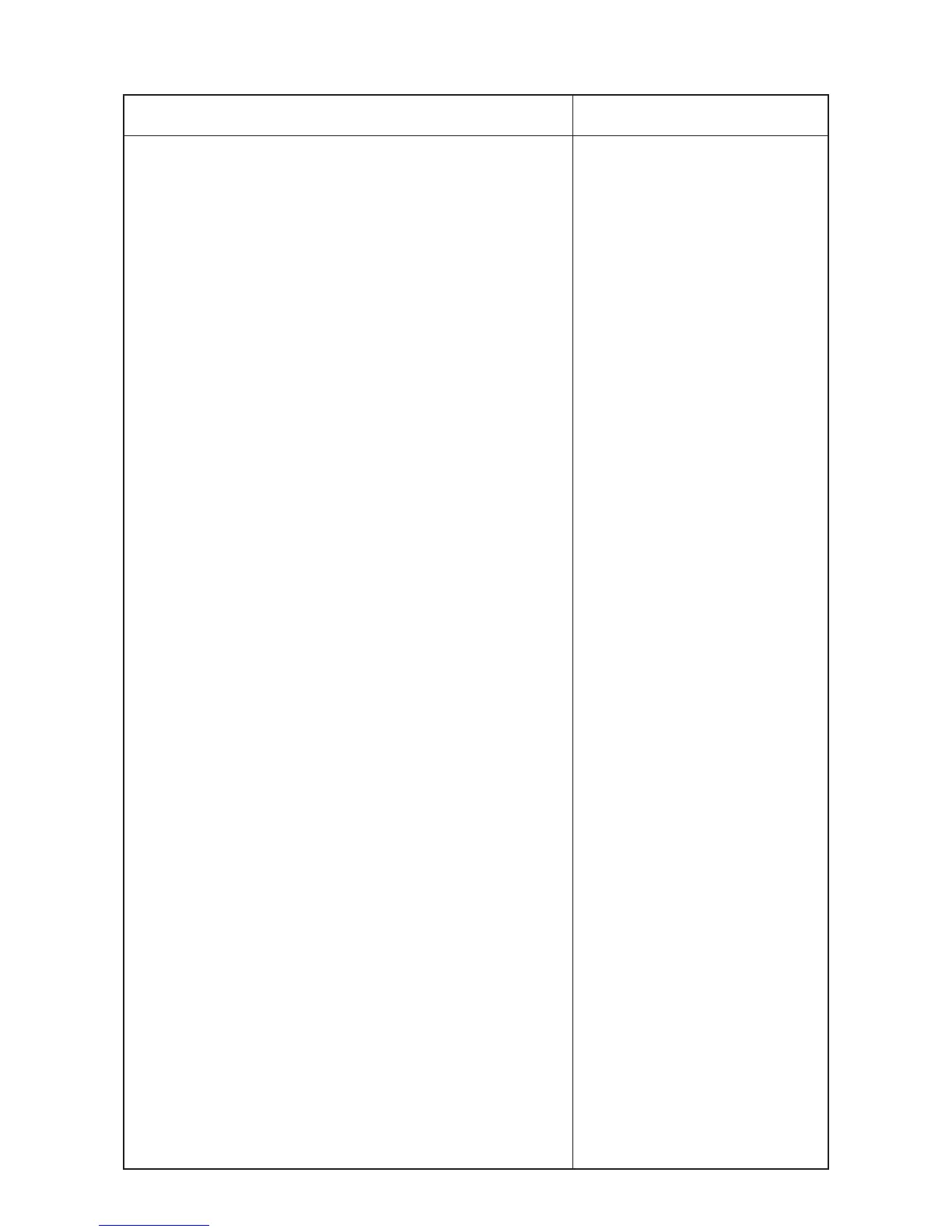

Adjustment Procedures Results of Improper Adjustment

1. Stop position after thread trimming

1) The standard needle stop position is the position where pointer

A on the machine arm aligns with white marker dot B on the

handwheel. (Main shaft timing : 57.5˚)

2) Stop the needle at UP position, and loosen screw 1 to perform

adjustment within the range of the slot.

™ To advance UP stop position a direction of C

™ To retard UP stop position a direction of D

2. DOWN stop position

1) The needle DOWN stop position when the pedal is returned to

the neutral position after the front part of the pedal is depressed

can be adjusted within the range of the slot by loosening screw

2 after making needle 3 stop at DOWN stop position.

™ To advance DOWN stop position a direction of E

™ To retard DOWN stop position a direction of F

(Caution) 1. Do not operate the machine with screws 1

and 2 loosened. In addition, just loosen

the screws, and do not remove them.

2. When the UP stop position is excessively

advanced, the sewing machine stops before

completion of the thread trimming motion,

and there is a possibility of the occurrence

that thread is not trimmed. In addition, when

it is excessively retarded, there is a

possibility that the needle tip projects the

bottom surface of the presser foot or the

sewing machine overruns at the time of UP

stop.

Use the sewing machine at the position

where pointer A on the machine arm aligns

with white marker dot B on the handwheel.

3. Do not move the pointer on the arm since it

has been factory-adjusted according to the

base of the height of the needle bar at the

time of delivery. In case it has been moved,

adjust the needle feed dial to “P = 0”, and

precisely adjust the distance from the top

end of needle bar 4 to the top surface of

throat plate 5 to 44.1 mm when the needle

comes down. In this state, make white

marker dot B on the handwheel align with

pointer A on the machine arm.

4. When the UP stop position is adjusted,

check whether the needle comes in contact

with the wiper.

Loading...

Loading...