−37 −

Adjustment Procedures Results of Improper Adjustment

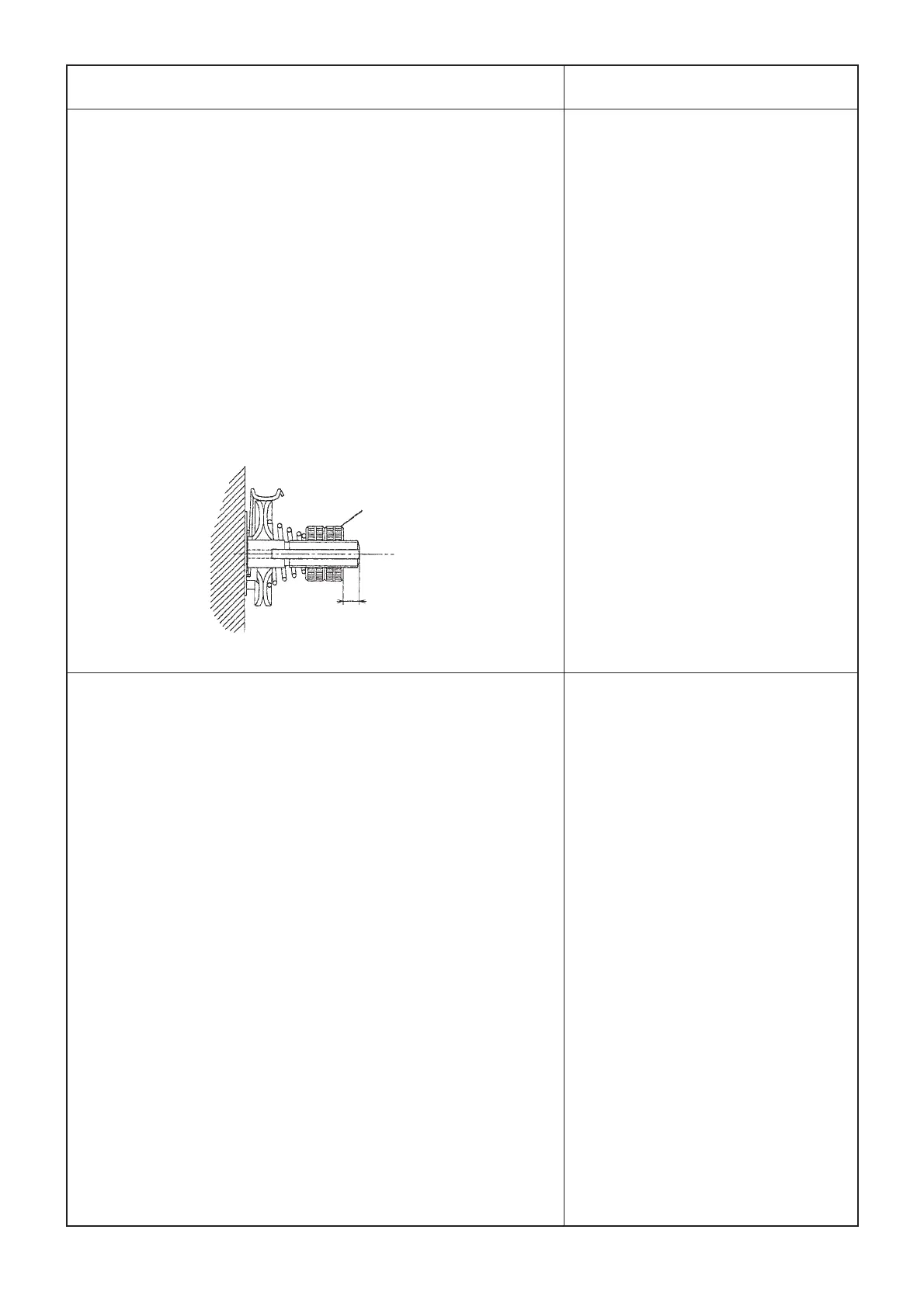

(3 to 4 mm)

1. Adjust so that thread breakage detecting plate 1 comes in

contact with thread take-up spring 2 without fail when the

machine head is not threaded. (Slack of the thread take-up

spring has to be 0.5 mm.)

2. When the stroke of thread take-up spring 2 has been

changed, loosen screw 3 and be sure to adjust thread

breakage detecting plate 1.

(Caution) Adjust so that thread breakage detecting plate 1

does not come in contact with any metallic part

other than thread take-up spring 2.

Assemble the nuts of the thread tension asm. as

shown in the figure.

1. Adjust so that a clearance of 0.5 to 1 mm is provided between

presser lifting lever 1 and stopper 2 when the presser lifting

solenoid works.

2. Loosen nut 4 in the presser lifting solenoid, turn the chain to

adjust the position, and securely fix the solenoid with shaft

section 3 of the presser lifting solenoid and nut 4.

(Make sure that presser lifting lever 1 comes in contact with

boss 5 of the bobbin thread trimmer driving arm when presser

lifting lever 1 has returned.

(Caution) When the needle thread trimer bounds even with

the aforementioned dimensions, adjust so that the

chain does not slacken when presser lifting lever

1 has returned.

(Assembling thread tension asm.)

Nut

™ If the detecting plate does not come

in contact with the spring, the needle

thread breakage cannot be

detected and the cloth cutting knife

works.

™ If the contacting force is too strong,

early breakage of the thread take-

up spring will occur.

™ If the clearance is small, presser

lifting lever 1 does not return to the

initial position and presser lifting

error will occur.

™ If the clearance is large, the needle

thread trimmer may bound when

presser lifting lever 1 has returned.

Loading...

Loading...