−5 −

Adjustment Procedures Results of Improper Adjustment

1. Adjust the timing by the needle rocking drive pinion.

<How to check after the adjustment>

Place a sheet of paper at the needle entry position, turn the

hand pulley by hand and make sure that the needle sways in

the lateral direction.

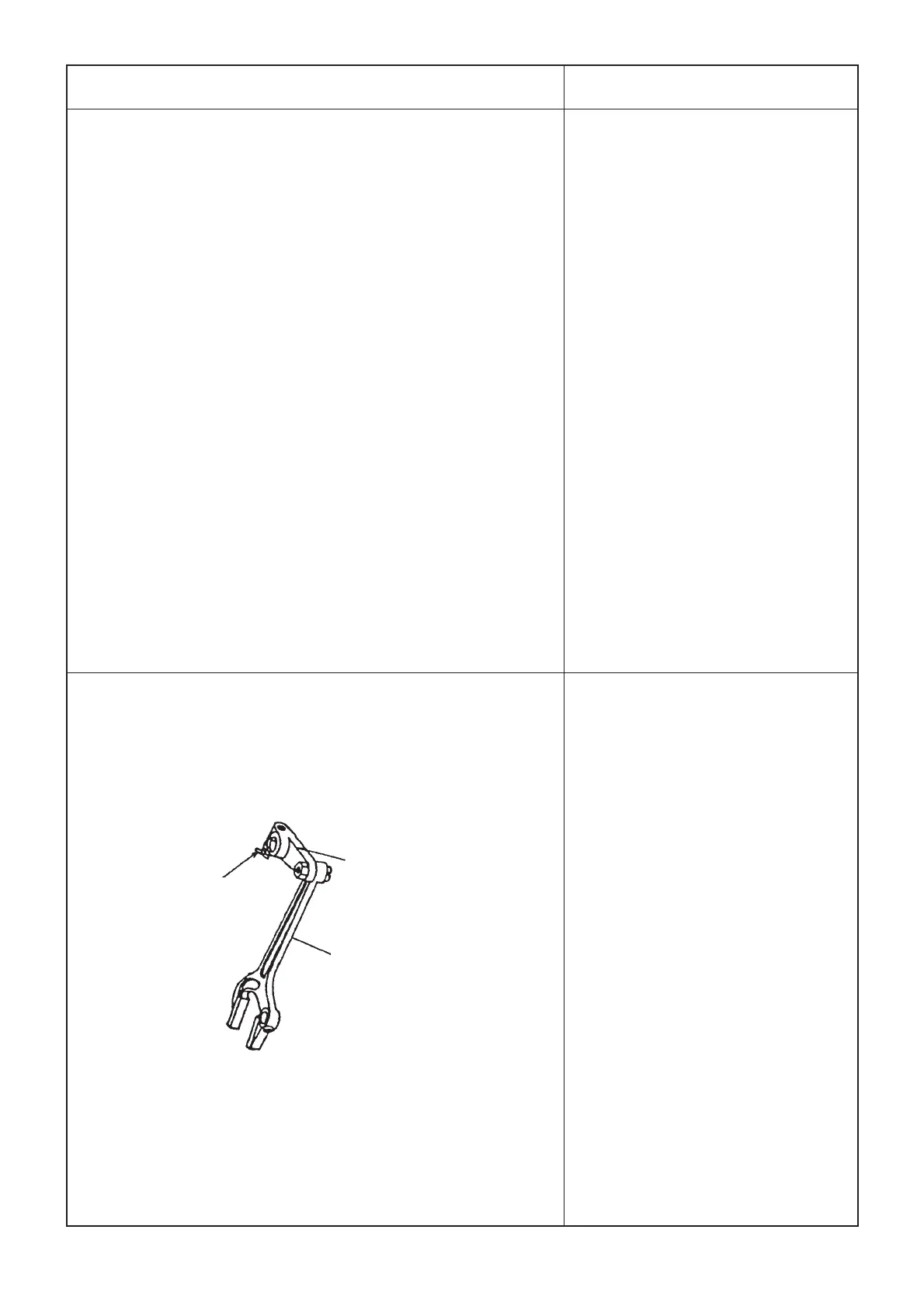

Place a block of 8 mm under the rod and press down the needle

bar rocking rod. Then, the rod comes down. In this state, loosen

the setscrew in the needle bar rocking arm, rear to adjust the

height.

(Caution) When tightening the setscrew in the needle bar

rocking arm, rear, tighten it so that there is no

thrust play between the needle bar rocking arm,

rear and the needle bar rocking shaft bushing.

Setscrew

Needle bar rocking

arm, rear

Needle bar rocking rod

™ When the engraved marker line is

not aligned, needle sways to cause

needle breakage, stitch skipping,

etc.

™ When the height of the needle bar

rocking rod is improper, stitch width

of parallel section of the right and

left sides will change.

™ If the needle entry position is

improper, when the needle stitch

width is increased, the other side

comes in contact with the needle

and the hole in the throat plate. As

a result, needle breakage or thread

breakage will result.

Loading...

Loading...