– 12 –

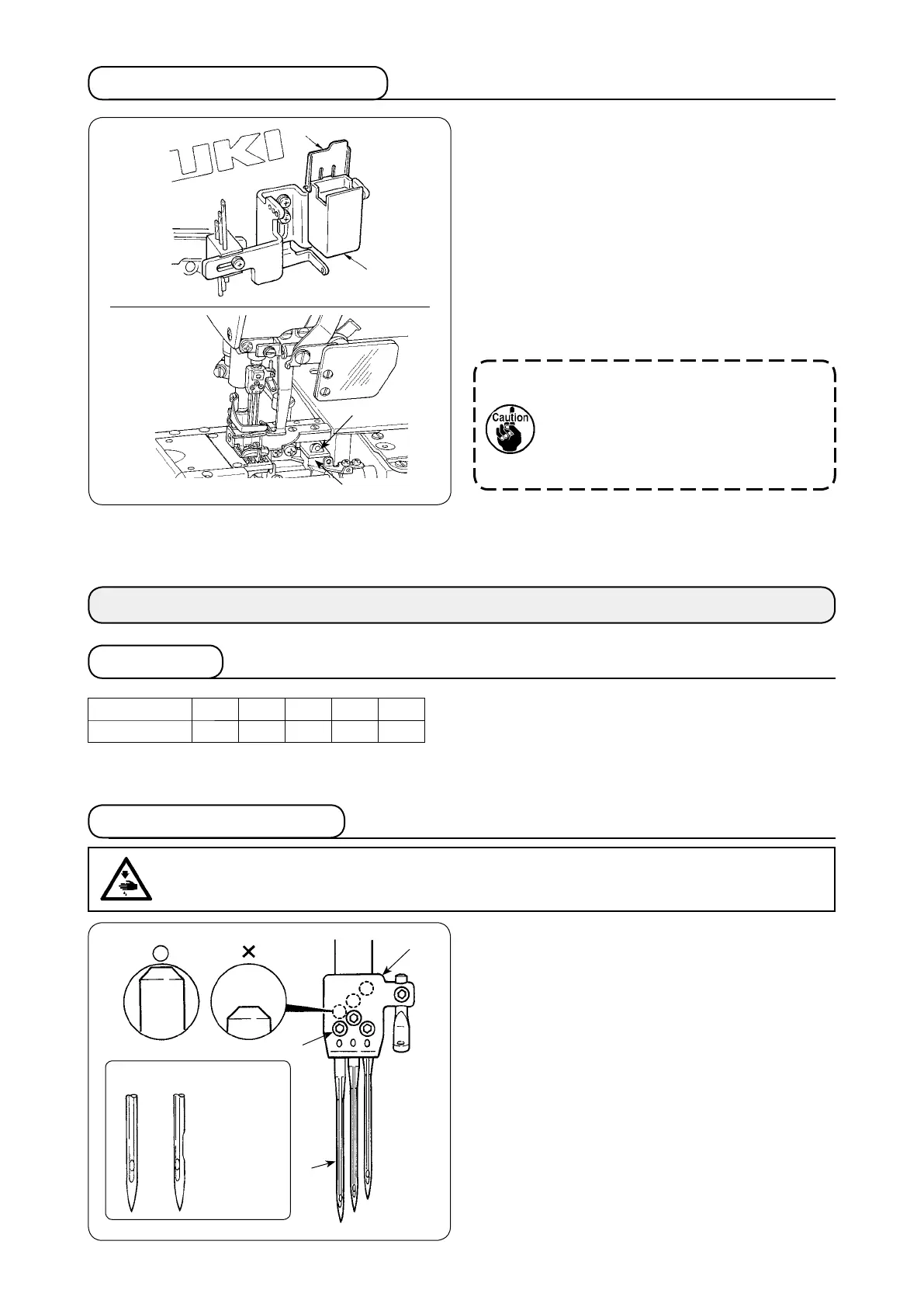

This sewing machine is provided with the silicon oil

lubricating unit as standard. In case of sewing at a high

speed, or using chemical thread or chemical fabric, use

the silicon oil lubricating unit to prevent thread break-

age or stitch skipping.

Oil used is silicon oil (dimethyl silicon).

Open cover

2

of silicon container

1

and make sure

that silicon oil enters needle thread, needle tip and sili-

con oil lubricating unit. If silicon oil is insufcient there,

supply it (dimethyl silicon).

When silicon oil adhered to the components

other than the silicon oil lubricating unit,

be sure to wipe it out. If the components to

which silicon oil adhered are kept without

wiping out the oil, sewing machine trouble

will be caused.

3. Silicon oil lubricating unit

1

2

%

.

OPERATION

1. Needle

The needle used for this sewing machine is UY128GAS.

For the needle No., select a proper needle in accordance with

the sewing conditions.

Japan No.

9 10 11 12 14

German No.

65 70 75 80 90

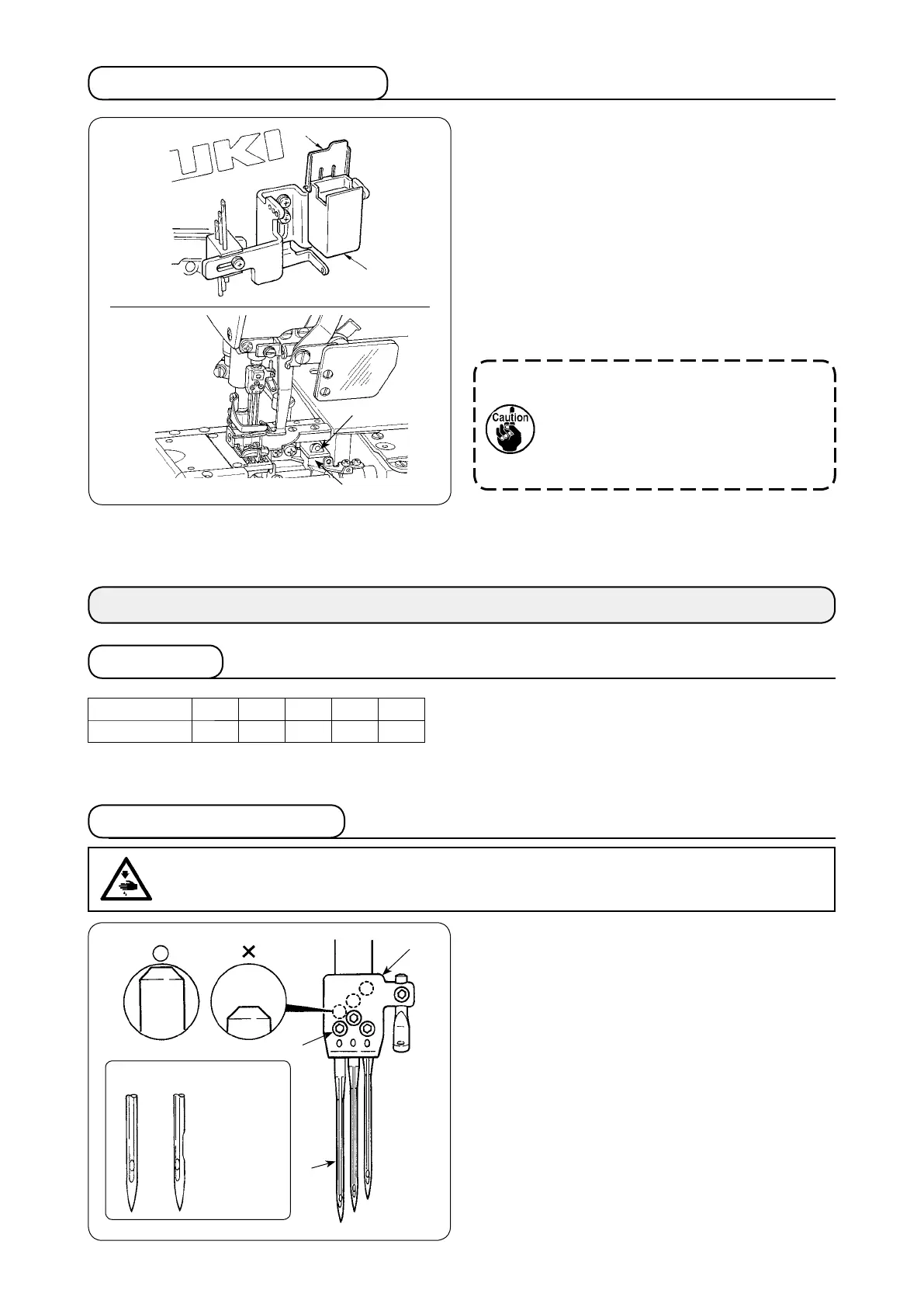

2. Attaching the needle

1) Loosen setscrew

2

of needle

1

with a screwdriver.

2) Hold the new needle with indented part facing to the

rear and insert it into the hole in needle clamp

3

un-

til the end of hole is reached.

3) Securely tighten setscrew

2

of the needle.

[

Scarf

○

×

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the fol-

lowing work after turning the power off and ascertaining that the motor is at rest.

1

2

1

2

3

Loading...

Loading...